Preparation method of graphite

A technology of graphene and graphite, which is applied in the field of graphene preparation, can solve the problems of small specific surface area, complex process and high cost of graphene, and achieve the effects of short reaction time, simple process and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

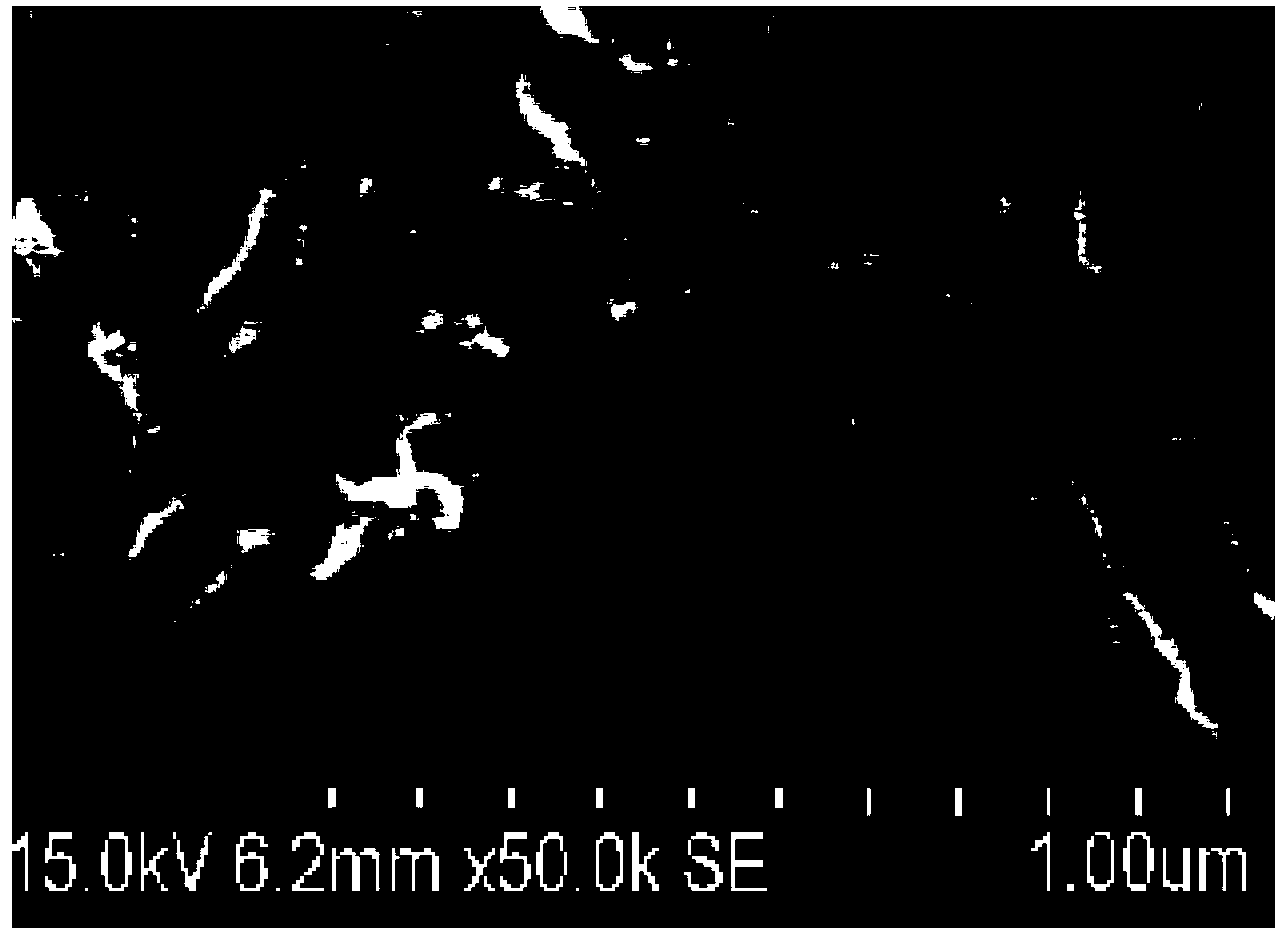

Image

Examples

Embodiment 1

[0030] A method for preparing graphene, comprising the steps of:

[0031] (1) Preparation of graphite oxide:

[0032] Get the graphite that purity is 99.5% and prepare graphite oxide, its concrete steps are:

[0033] Add 20g of 50-mesh graphite, 10g of potassium persulfate and 10g of phosphorus pentoxide into concentrated sulfuric acid at 80°C, stir evenly, cool for 6h, wash until neutral, and dry; add the dried sample to 230mL of concentrated sulfuric acid at 0°C Add 60g of potassium permanganate, keep the temperature of the mixture at 20°C, then keep it in an oil bath at 35°C for 2h, then slowly add 920mL of deionized water; after 15min, add 2.8L of deionized water (which contains 50mL of 30% hydrogen peroxide), after which the color of the mixture turned bright yellow, suction filtered while hot, then washed with 5L of 10% hydrochloric acid, suction filtered, and vacuum dried at 60°C for 48 hours to obtain graphite oxide.

Embodiment 2

[0039] A method for preparing graphene, comprising the steps of:

[0040] (1) Preparation of graphite oxide:

[0041] Get the graphite that purity is 99.5% and prepare graphite oxide, its concrete steps are:

[0042] Add 20g of 50-mesh graphite, 10g of potassium persulfate and 10g of phosphorus pentoxide into concentrated sulfuric acid at 80°C, stir evenly, cool for 7 hours, wash until neutral, and dry; add the dried sample to 230mL of concentrated sulfuric acid at 0°C Add 60g of potassium permanganate, keep the temperature of the mixture at 18°C, then keep it in an oil bath at 35°C for 2h, then slowly add 920mL of deionized water; after 15min, add 2.8L of deionized water (which contains 50mL of 30% hydrogen peroxide), after which the color of the mixture turned bright yellow, suction filtered while hot, then washed with 5L of 10% hydrochloric acid, suction filtered, and vacuum dried at 60°C for 48 hours to obtain graphite oxide.

[0043] (2) Drying: the obtained graphite ox...

Embodiment 3

[0047] A method for preparing graphene, comprising the steps of:

[0048] (1) Preparation of graphite oxide:

[0049] Get the graphite that purity is 99% and prepare graphite oxide, its specific steps are:

[0050] Add 20g of 50-mesh graphite, 10g of potassium persulfate and 10g of phosphorus pentoxide into concentrated sulfuric acid at 80°C, stir evenly, cool for 8 hours, wash until neutral, and dry; add the dried sample to 230mL of concentrated sulfuric acid at 0°C Add 60g of potassium permanganate, keep the temperature of the mixture at 16°C, then keep it in an oil bath at 35°C for 2h, then slowly add 920mL of deionized water; after 15min, add 2.8L of deionized water (which contains 50mL of 30% hydrogen peroxide), after which the color of the mixture turned bright yellow, suction filtered while hot, then washed with 5L of 10% hydrochloric acid, suction filtered, and vacuum dried at 60°C for 48 hours to obtain graphite oxide.

[0051] (2) Drying: The obtained graphite oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com