Method for preparing metal soft magnetic powder core by adopting inorganic insulation adhesive particles

A metal soft magnetic and inorganic insulation technology, applied in the direction of inorganic material magnetism, magnetic materials, magnetic objects, etc., can solve the problems of low tensile strength, reduced comprehensive magnetic properties, and increased power loss, so as to improve production efficiency and increase diameter effect on tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

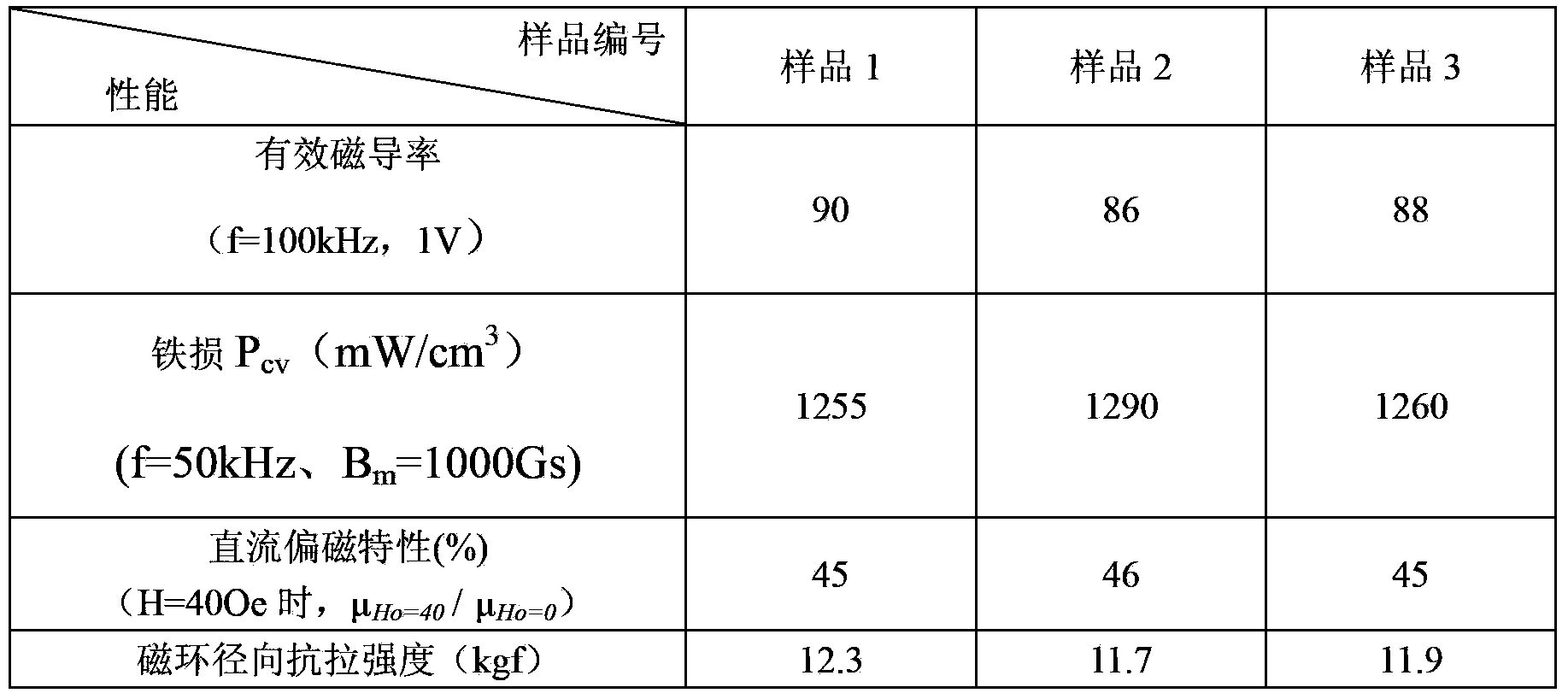

Embodiment 1

[0023] (1) Mix iron powders of different meshes, among which, iron powders of -100 mesh to +200 mesh account for 10% of the total mass, and iron powders of -200 mesh to +400 mesh account for 80% of the total mass. -400 mesh iron powder accounts for 10% of the total mass;

[0024] (2) Add hydrogen peroxide passivator to the iron powder prepared in step (1) for passivation treatment, the quality of hydrogen peroxide is 0.1% of the total weight of the magnetic powder;

[0025] (3) Fully mix the inorganic insulating particles directly with the passivated iron powder, the mass of the inorganic insulating particles is 0.1% of the total weight of the iron powder, and the mass percentage of the inorganic insulating bonding particles is 30%P 2 o 5 , 60%ZnO, 10%B 2 o 3 ;

[0026] (4) Add 0.01% by weight of kaolin insulating agent, and then add 0.2% by weight of zinc stearate release agent;

[0027] (5) Press the mixture obtained in step (4) under a pressure of 1200 MPa to form a ri...

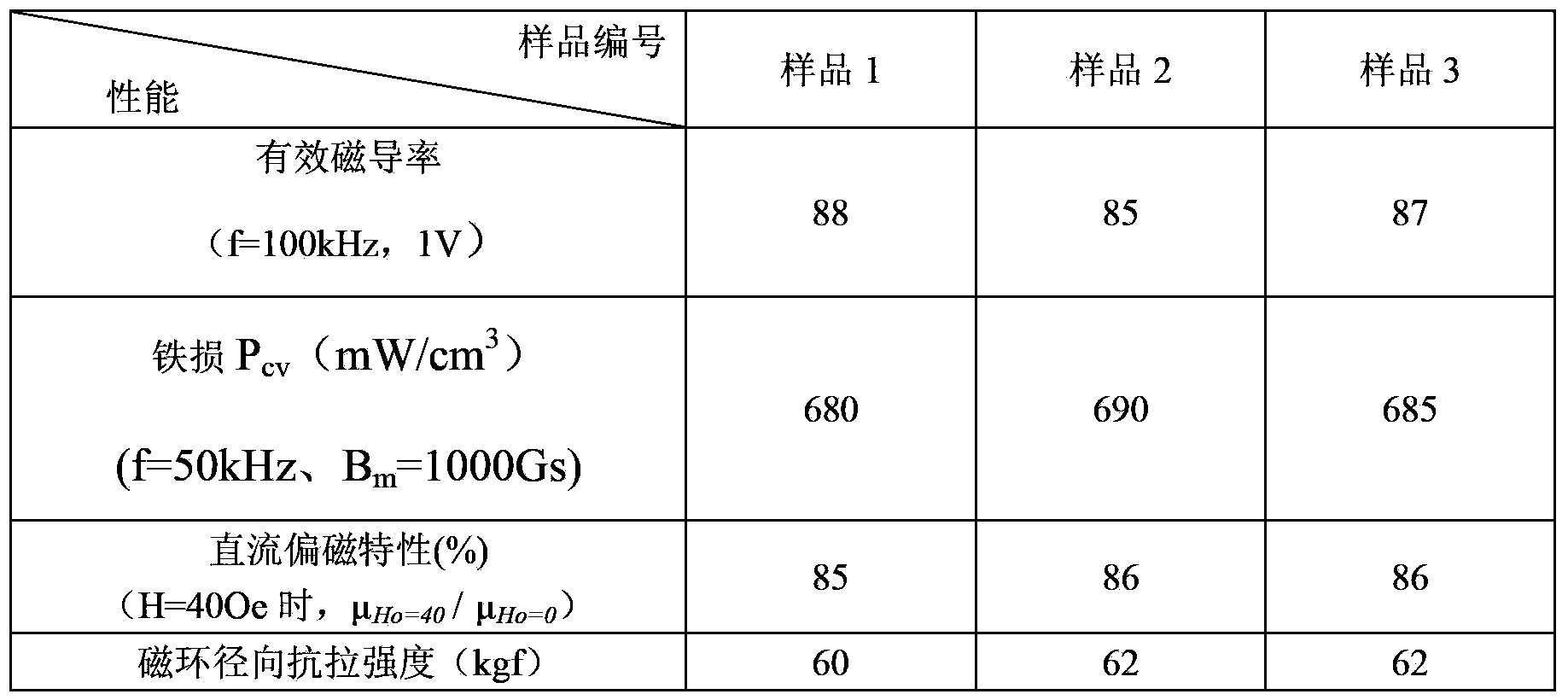

Embodiment 2

[0031] (1) Mix iron-silicon powders of different meshes, among which, iron-silicon powders of -100 mesh to +200 mesh account for 30% of the total mass, and iron-silicon powders of -200 mesh to +400 mesh account for 40% of the total mass. -400 mesh iron-silicon powder accounts for 30% of the total mass;

[0032] (2) Add a phosphoric acid passivator to the iron-silicon powder prepared in step (1) for passivation treatment, and the quality of phosphoric acid is 5% of the total weight of the iron-silicon powder;

[0033] (3) Fully mix the inorganic insulating particles directly with the passivated iron-silicon powder, the mass of the inorganic insulating particles is 3% of the total weight of the iron-silicon powder; the mass percentage component of the inorganic insulating bonding particles is 30%P 2 o 5 , 59.9%ZnO, 10%B 2 o 3 , 0.02%CuO, 0.02%Bi 2 o 3 , 0.02%SrO 5 , 0.01%Al 2 o 3 , 0.01%Na 2 O, 0.01%Li 2 o 5 , 0.01%PbO;

[0034] (4) Add 0.1% by weight of mica powder ...

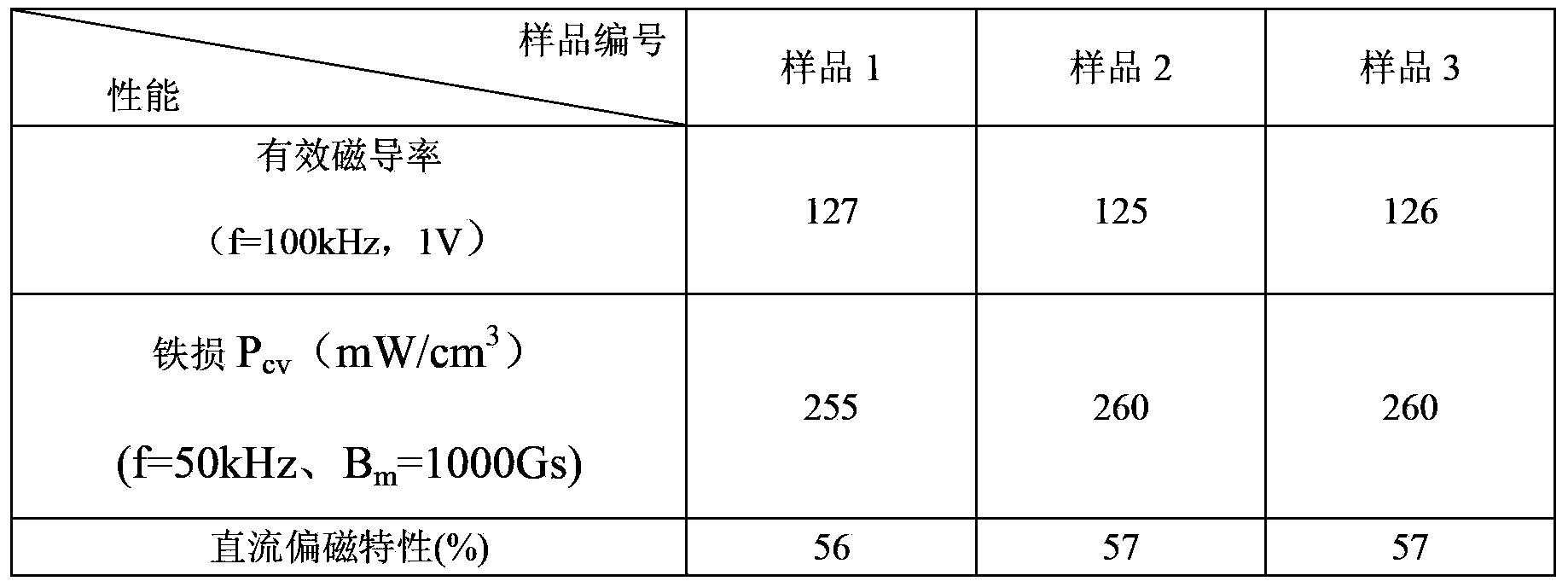

Embodiment 3

[0039] (1) Mix sendust powders of different meshes, among them, -100 mesh to +200 mesh sendust powder accounts for 10% of the total mass, and -200 mesh to +400 mesh sendust powder accounts for 10% of the total mass 70%, -400 mesh sendust powder accounts for 20% of the total mass;

[0040] (2) Add a passivating agent to the sendust powder prepared in step (1) for passivation treatment, the passivator is phosphoric acid and hydrogen peroxide; wherein, the mass of phosphoric acid is the total mass of sendust mixed powder 0.3%, the mass of hydrogen peroxide is 0.5% of the total mass of sendust mixed powder;

[0041] (3) Fully mix the inorganic insulating particles directly with the passivated sendust powder, the mass of the inorganic insulating particles is 0.8% of the total weight of the sendust powder; the mass percentage component of the inorganic insulating bonding particles is 30%P 2 o 5 , 35%ZnO, 10%B 2 o 3 , 20%CuO, 1%Bi 2 o 3 , 1%SrO 5 , 1%Al 2 o 3 , 1%Na 2O, 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com