Temperature measurement structure suitable for growing SiC crystal system by PVT (physical vapor transportation) method

A technology of crystal and temperature measuring tube, which is applied in the field of temperature measurement in the growth process of SiC crystal, can solve the problems of affecting the temperature gradient of the growth system and the blockage of the temperature measuring hole, so as to avoid the temperature gradient change, improve the yield, and avoid polytype defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described with reference to the accompanying drawings and the following embodiments. It should be understood that the accompanying drawings and the following embodiments are only used to illustrate the present invention rather than limit the present invention.

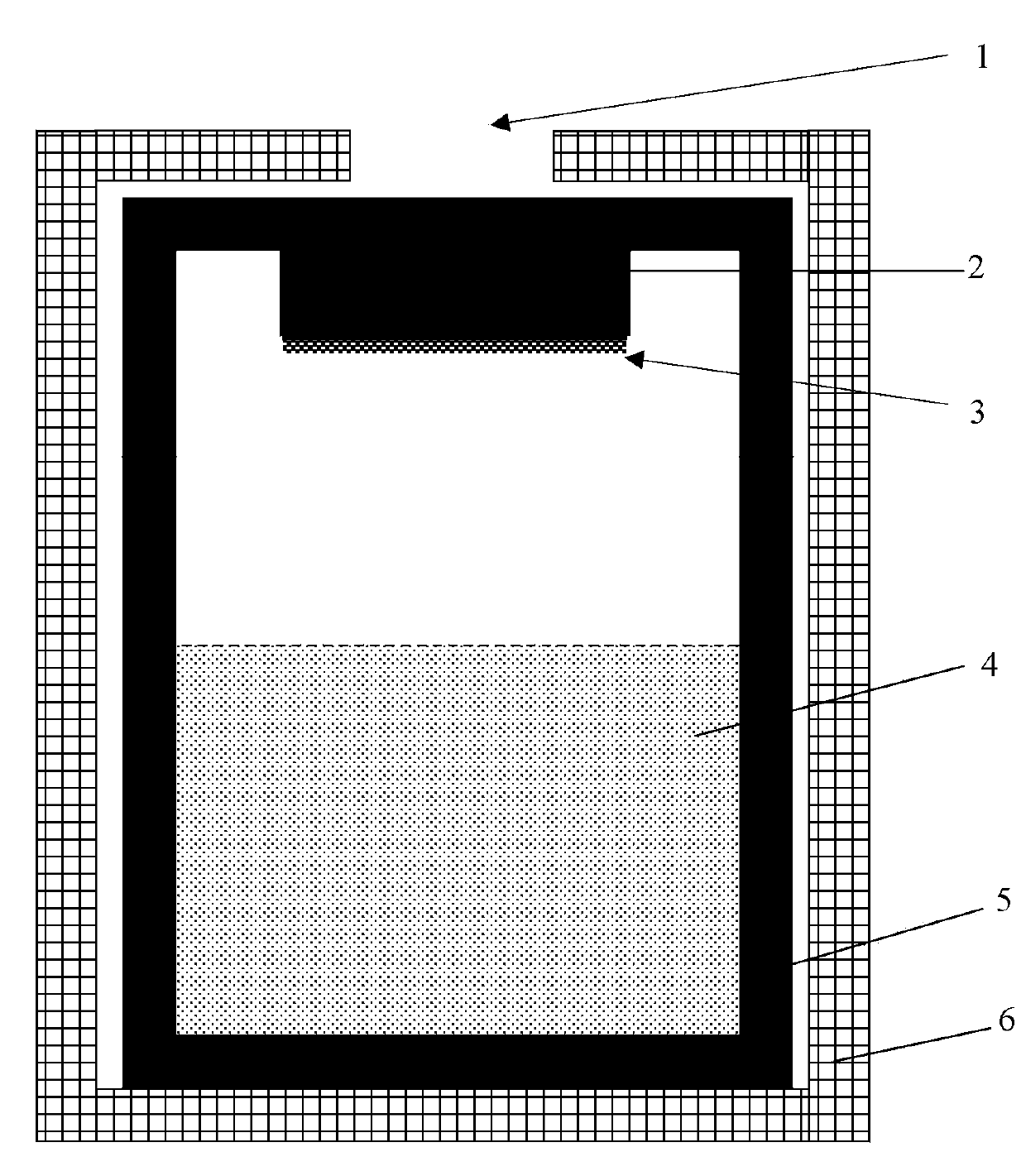

[0029] figure 1 It is a schematic diagram of a growth system for growing SiC crystals by the known physical vapor transport method. Such as figure 1 The known physical vapor transport method for growing SiC crystals has a crystal growth chamber surrounded by a crucible 5, a seed crystal support 2 arranged on the top of the growth chamber, and a crystal growth chamber around the crystal growth chamber. Insulation layer 6. Usually graphite crucible 5 is used, SiC raw material 4 is placed in the lower part of the growth chamber, and seed crystal support 2 with seed crystal 3 fixed is fixed on the top of the growth chamber surrounded by crucible 5 . By controlling the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com