Liquid crystal alignment agent, and liquid crystal alignment film and liquid crystal display element

A liquid crystal alignment agent and a technology of liquid crystal alignment, applied in liquid crystal materials, optics, instruments, etc., can solve problems such as inapplicability, reduced alignment ability of liquid crystal alignment film, poor uniformity of liquid crystal molecule tilt angle, etc., and achieve the best process stability , the effect of good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

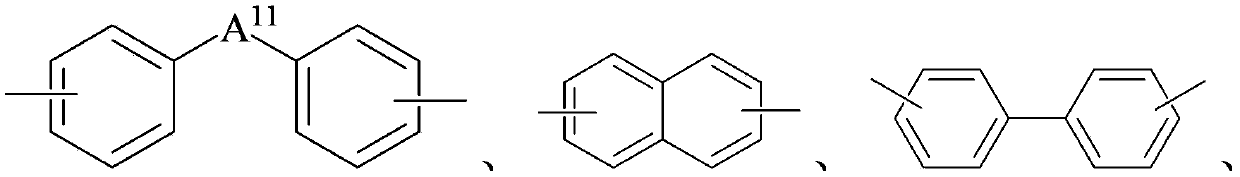

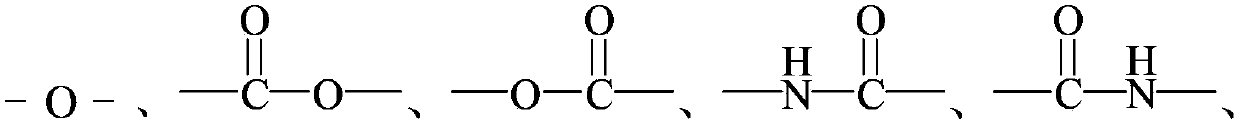

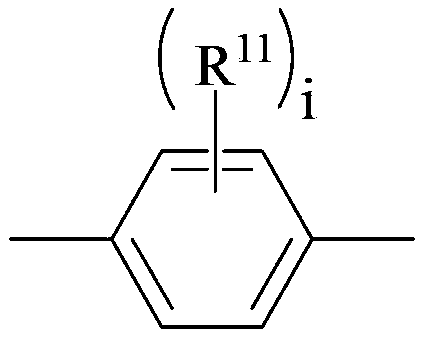

[0150] The preparation method of the polyimide polymer comprises dissolving the mixture comprising the tetracarboxylic dianhydride component, the polyamine component shown in formula (I) and the diamine component in a solvent, and performing a polymerization reaction to form a polyamide acid polymer, and in the presence of a dehydrating agent and a catalyst, further heating and dehydration ring-closing reaction, so that the amic acid functional group in the polyamic acid polymer is converted into an imide functional group (ie imide) through a dehydration ring-closure reaction. amination) to obtain a polyimide polymer.

[0151] Prepare the tetracarboxylic dianhydride component used in the polyimide polymer, the polyamine component and the diamine component shown in formula (I) and the tetracarboxylic acid used in the above-mentioned preparation polyamic acid polymer The dianhydride component and the polyamine component represented by the formula (I) are the same as the diamine ...

Synthetic example 1

[0189] A nitrogen inlet, a stirrer, a condenser tube and a thermometer are arranged on a four-necked conical flask with a capacity of 500 milliliters, and nitrogen is introduced, and the feed composition is added to include: 5.37 grams (0.01 mole) of the diamine compound of formula (1), 40.55 gram (0.0375 mol) of p-phenylenediamine, 0.31 gram (0.0025 mol) of 1,2,4-triaminobenzene and 80 gram of nitrogen-methyl-2-pyrrolidone were stirred at room temperature until dissolved. Then add 10.91 grams (0.05 moles) of pyromellitic dianhydride and 20 grams of nitrogen-methyl-2-pyrrolidone, and react at room temperature for 2 hours. After the reaction, the reaction solution is poured into 1500 milliliters of water to polymerize After the polymer was filtered, washed with methanol and filtered three times, it was placed in a vacuum oven and dried at a temperature of 60° C. to obtain the polyamic acid polymer (A-1-1).

Synthetic example 2~5

[0191] Synthesis example 2~5 is to prepare this polyamic acid polymer with the step identical with synthesis example 1, difference is: change the diamine compound shown in tetracarboxylic dianhydride component, formula (II), formula ( I) the polyamine component shown, or the kind and usage amount of other diamine compounds, as shown in Table 1.

[0192] [Preparation of polyimide polymer]

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com