Epoxy composite material and preparation method thereof

A composite material and epoxy technology, applied in the field of preparation of epoxy composite materials, can solve problems such as easy generation of bubbles, complexity, and poor rheological properties of the system, so as to simplify the production process, reduce production costs, and improve breakdown strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

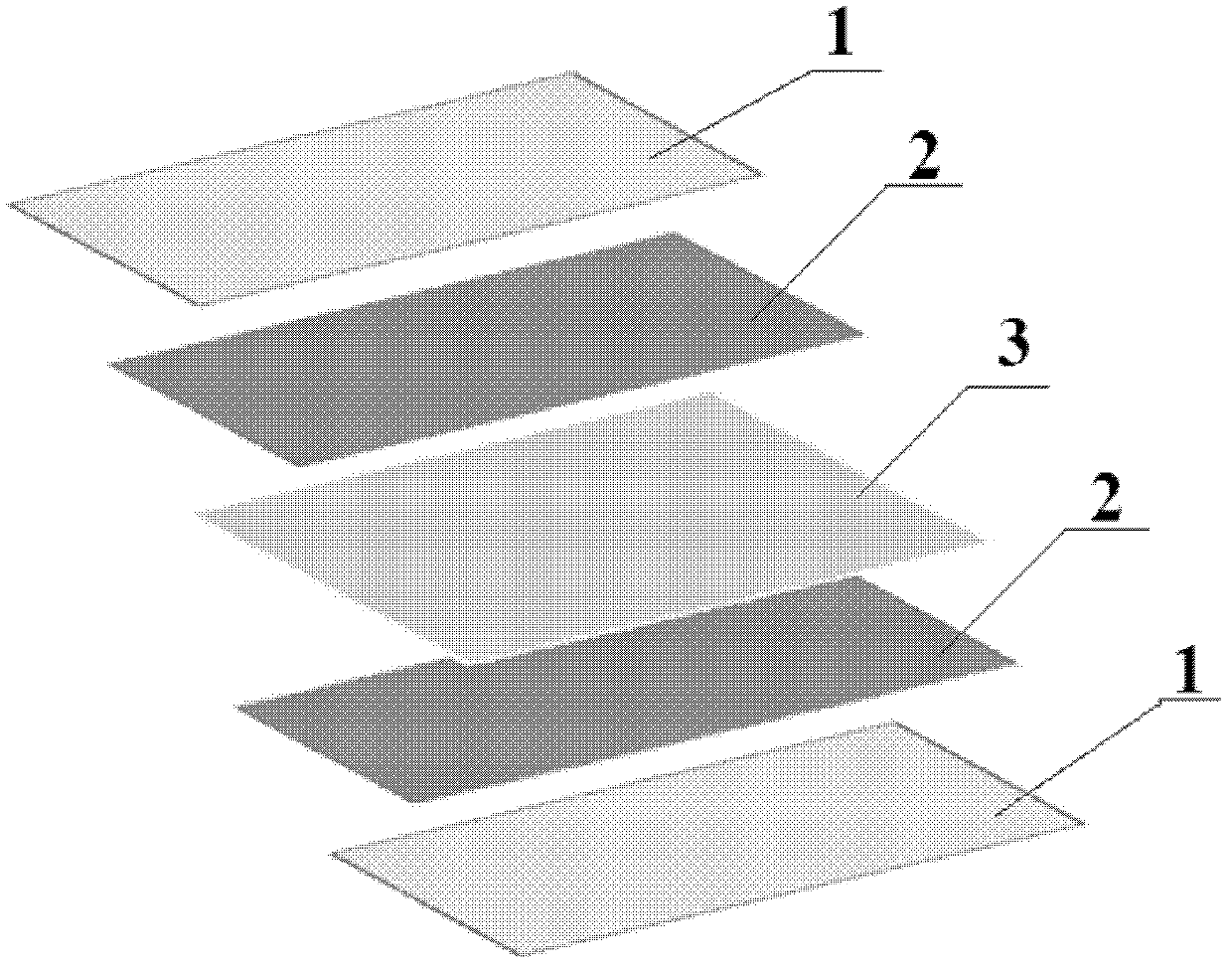

[0028] The invention provides a kind of preparation method of epoxy composite material, this method comprises:

[0029](1) stirring and mixing the conductive nanofiller with a part of epoxy resin, and grinding the mixture obtained after stirring and mixing to obtain a masterbatch;

[0030] (2) Mix the masterbatch obtained in step (1) with another part of epoxy resin and curing agent at 50-80°C, and then remove air bubbles;

[0031] (3) solidifying and molding the material obtained after removing air bubbles;

[0032] Wherein, the total consumption of epoxy resin in step (1) and (2) is 100:0.001-0.5 with the weight ratio of conductive nanofiller in step (1), the consumption of epoxy resin in step (1) and step (2 The weight ratio of epoxy resin in ) is 1:0.1-100, and the stirring and mixing conditions in step (1) make the kinematic viscosity of the mixture obtained after stirring and mixing at 60° C. be 5-18 Pa·s.

[0033] In step (1), stirring and mixing the conductive nanofi...

Embodiment 1

[0054] This example is used to illustrate the epoxy composite material of the present invention and its preparation method.

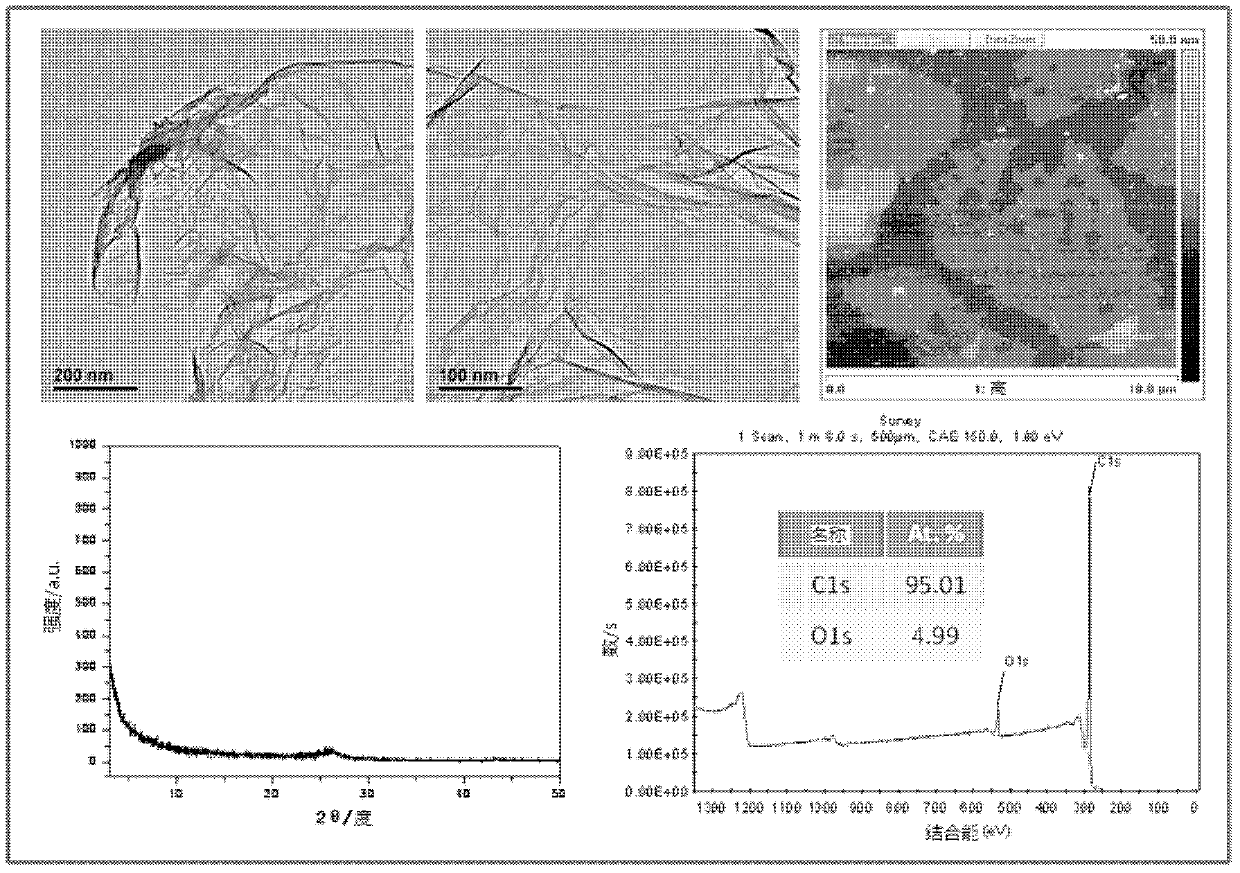

[0055] With the bisphenol A epoxy resin of 30 weight parts (Huntsman company, model is Epoxy value is about 0.52mol / 100g, the same below) is added into high-speed stirrer (Germany VMA-Getzmann company, model DISPERMAT AE), then the reduced graphene oxide of 0.01 weight part (purchased from Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, Its relevant parameters such as figure 2 shown) was added into two batches evenly, stirred and mixed for 1.5 hours at a rotating speed of 3000 rpm to obtain a mixture with a dynamic viscosity of 10 Pa·s at 60°C, and then place the obtained mixture in an airtight container at room temperature for 20 Hours, after which the obtained material was ground with a three-roll mill (model EXAKT 80E), operating in two modes successively. Among them, in the spacing mode, the ratio of the front and rear roller s...

Embodiment 2-6

[0063] This example is used to illustrate the epoxy composite material of the present invention and its preparation method.

[0064] Epoxy composites were prepared according to the method of Example 1, except that the amount of reduced graphene oxide was added as shown in Table 1 below, so that epoxy composite films with a thickness of about 200 microns were correspondingly prepared.

[0065] Table 1

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com