Bidirectional continuous glass fiber reinforced PP (polypropylene) flame-retardant aging-resistant plate as well as preparation method thereof

An anti-aging and anti-aging agent technology, which is applied in the field of two-way continuous glass fiber reinforced polypropylene resin sheet and its preparation, can solve the problems of anti-aging agent compounding, mechanical property decline, short service life, etc., and achieve good compoundability , high mechanical properties, the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

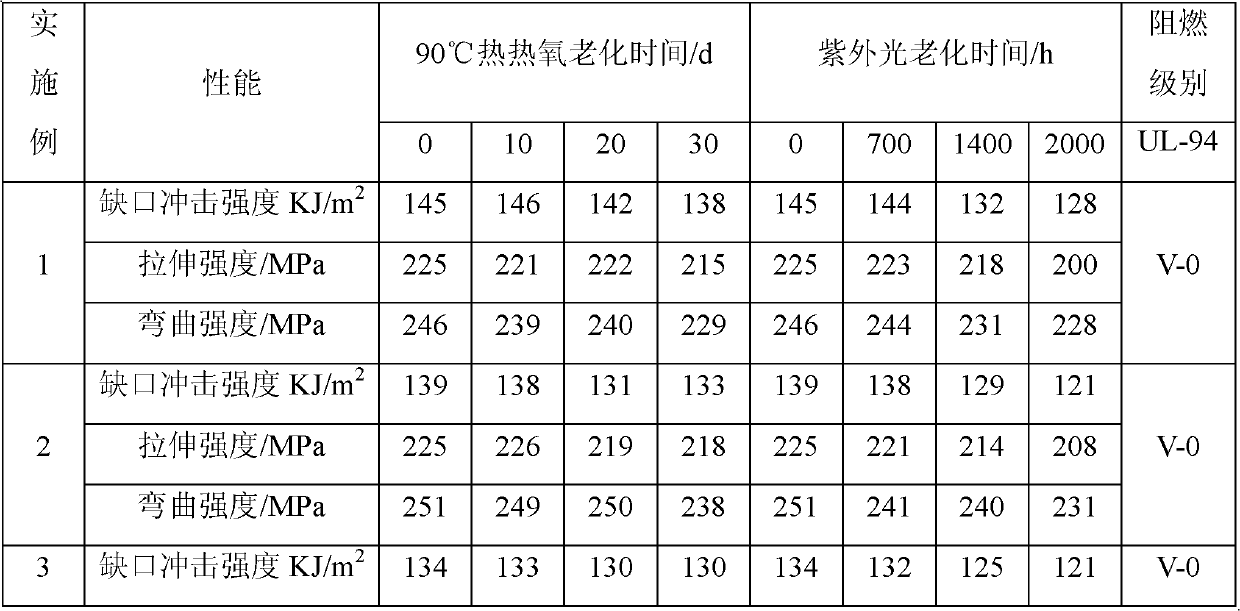

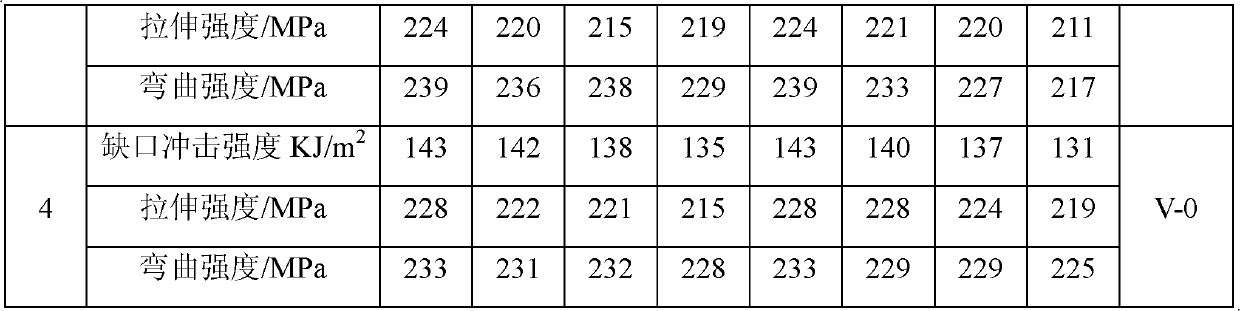

Examples

Embodiment 1

[0053] (1) the polypropylene resin of 10 parts by weight, the PP-based flame retardant masterbatch of 40 parts by weight, the antioxidant 1010 of 0.3 part (tetrakis [β-(3 ', 5 '-di-tert-butyl -4'-hydroxyphenyl) propionic acid] pentaerythritol ester), 0.9 parts of antioxidant 168 (three [2.4-di-tert-butylphenyl] phosphite), 0.15 parts of main antiaging agent UV326 (2-( 2'-hydroxyl-3'tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole) and 0.15 parts of auxiliary anti-aging agent HALS770 (bis(2,2,6,6-tetra Methyl-4-piperidinyl) sebacate) mixture, after fully mixing in a high-speed mixer, dry the mixture at 80°C for 1 hour, add it to the extruder, and melt it at 240°C Composite with 50 parts by weight of oven-dried continuous glass fibers with a moisture content of less than 0.01%, and flatten to make continuous glass fiber reinforced polypropylene (PP / GF) unidirectional prepreg tape;

[0054] (2) Cut the continuous glass fiber reinforced polypropylene unidirectional prepreg tape ...

Embodiment 2

[0059] (1) the polypropylene resin of 15 parts by weight, the PP base flame retardant masterbatch of 35 parts by weight, the antioxidant 1010 of 0.4 part (tetrakis [β-(3 ', 5 '-di-tert-butyl -4'-hydroxyphenyl) propionic acid] pentaerythritol ester), 1.2 parts of antioxidant 168 (three [2.4-di-tert-butylphenyl] phosphite), 0.17 parts of main antiaging agent UV326 (2-( 2'-hydroxyl-3'tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole) and 0.15 parts of auxiliary anti-aging agent HALS770 (bis(2,2,6,6-tetra Methyl-4-piperidinyl) sebacate) mixture, after being thoroughly mixed in a high-speed mixer, the mixture was dried at 80°C for 1 hour, and melted at 235°C with 50 parts by weight After oven drying, the moisture content is less than 0.01% continuous glass fiber composite, and flattened to make continuous glass fiber reinforced polypropylene unidirectional prepreg tape;

[0060] (2) Cut the continuous glass fiber reinforced polypropylene unidirectional prepreg tape (prepreg tape s...

Embodiment 3

[0065] (1) the polypropylene resin of 20 parts by weight, the PP base flame retardant masterbatch of 30 parts by weight, the antioxidant 1010 of 0.5 part (tetrakis [β-(3 ', 5 '-di-tert-butyl -4'-hydroxyphenyl) propionic acid] pentaerythritol ester), 1.5 parts of antioxidant 168 (three [2.4-di-tert-butylphenyl] phosphite), 0.2 parts of main antiaging agent UV326 (2-( 2'-hydroxyl-3'tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole) and 0.2 parts of auxiliary anti-aging agent HALS770 (bis(2,2,6,6-tetra Methyl-4-piperidinyl) sebacate) mixture, after fully mixing uniformly in a high-speed mixer, drying the mixture at 80°C for 1 hour, melting at 240°C with 50 parts by weight Parts are oven-dried and the moisture content is less than 0.01% continuous glass fiber composite, and flattened to make a unidirectional prepreg tape;

[0066] (2) Cut the continuous glass fiber reinforced polypropylene unidirectional prepreg tape (prepreg tape specifications: thickness 0.25mm, width 650mm, le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com