Preparation method for synthesizing CdSe/CdS core-shell structure quantum dots through one step

A technology of core-shell structure and quantum dots, which is applied in the field of preparation of metal oxide quantum dots, can solve the problems of difficult nanomaterial synthesis, long reaction time, and highly toxic raw materials, and achieve uniform size distribution, simple preparation method, and easy The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

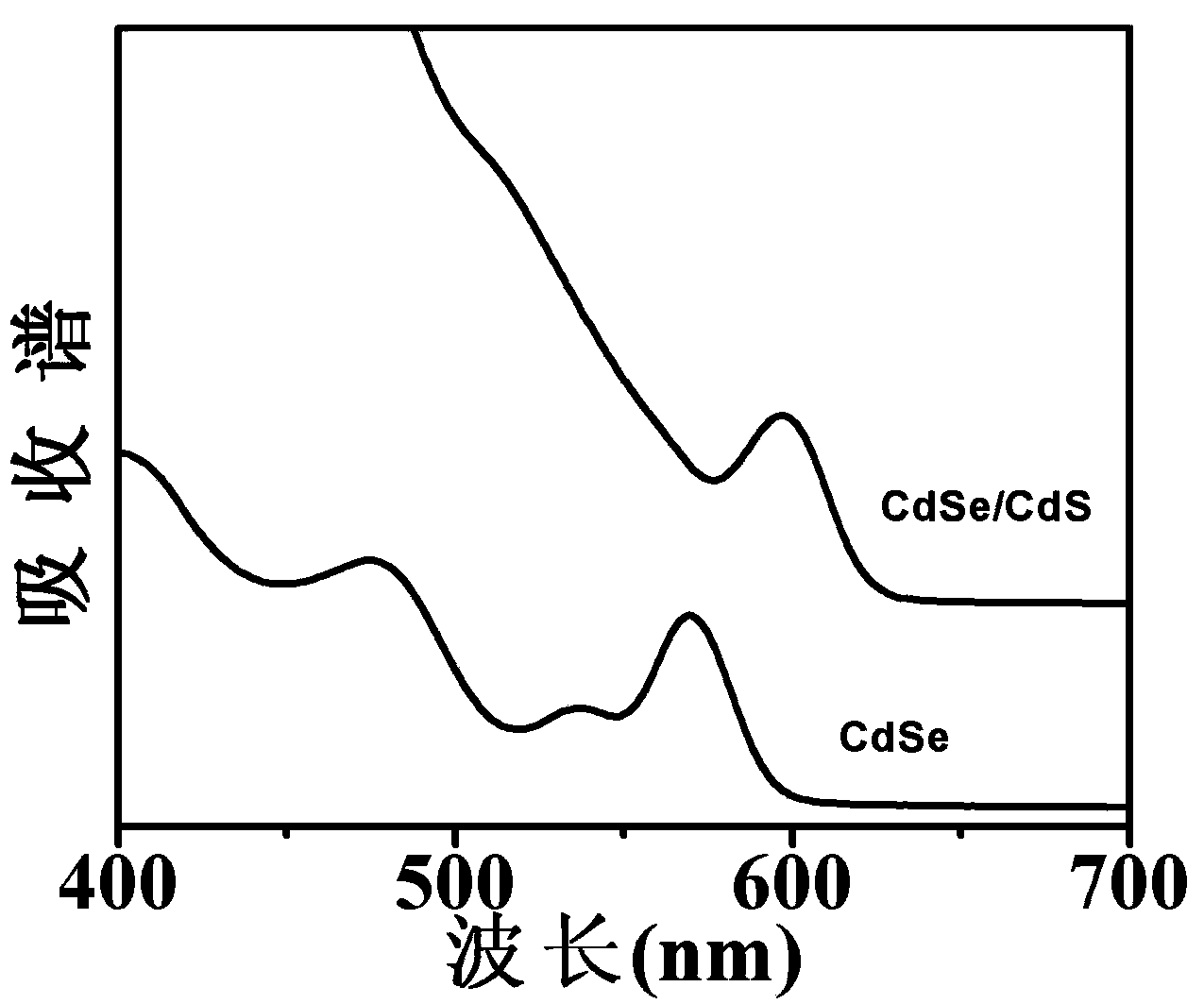

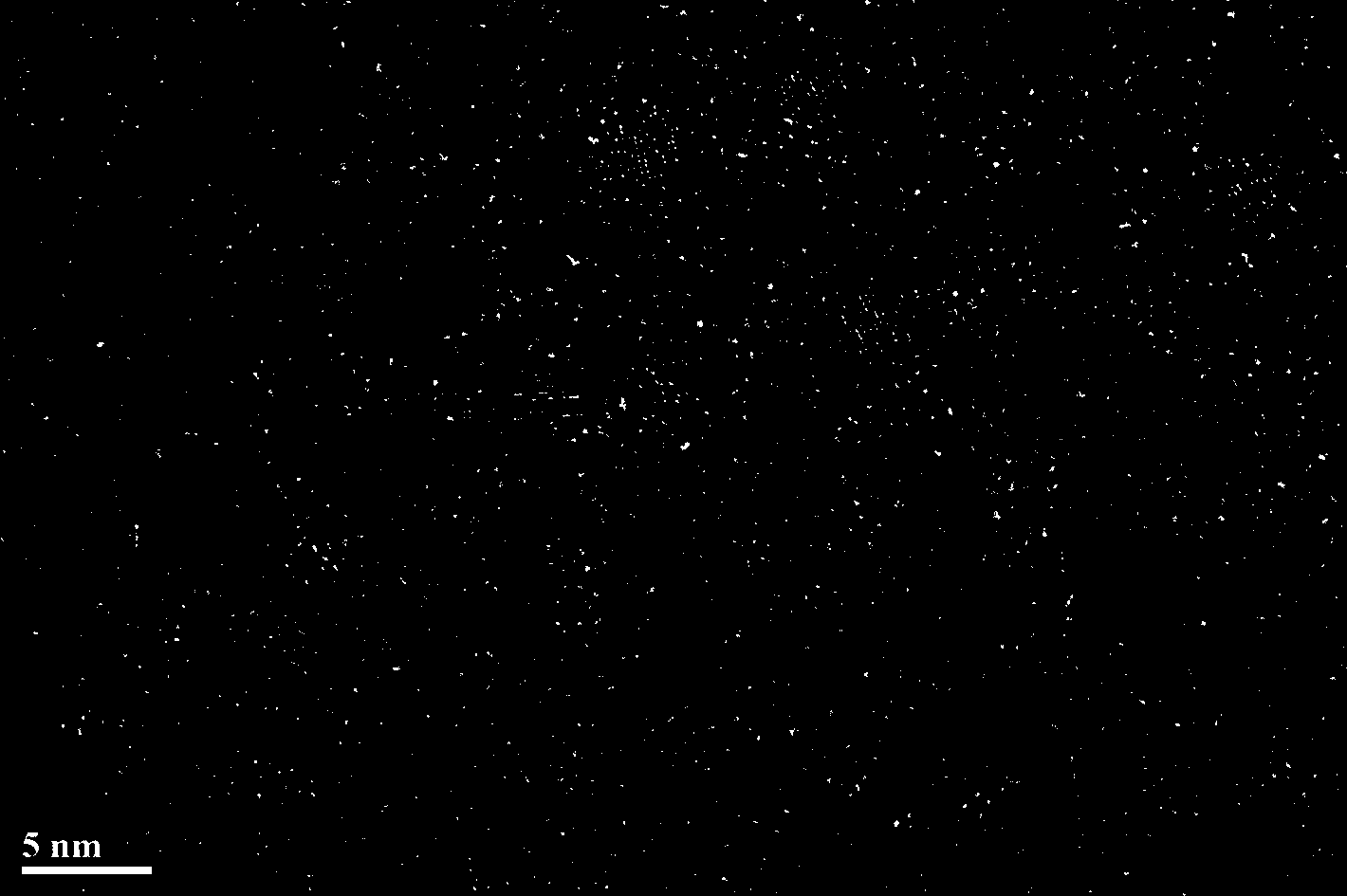

[0026] Weigh 0.2842 g of selenium powder and place it in a pear-shaped bottle, inject 2 ml of TOP into the pear-shaped bottle in an anhydrous and oxygen-free glove box and seal it; take out the pear-shaped bottle from the glove box, and the Se powder can be dissolved after ultrasonication, Prepare TOPSe solution; weigh 0.018 g of cadmium ethyl xanthate, 0.1032 g of cadmium stearate and place it in a 10 ml centrifuge tube, inject 1 ml of oleic acid, 1 ml of oleylamine and 3 ml of ten Octacene, ultrasound, to obtain the cadmium precursor; weigh 0.077 g of CdO powder and place it in a three-necked flask, inject 1 ml of oleic acid (OA) and 8 ml of octadecene (ODE) into the three-necked flask, and set up an anhydrous In the anaerobic system, pass high-purity Ar (99.999%), heat the solution in the three-necked flask to 280 °C after 30 min, and stop heating after the CdO is completely dissolved; take 1 g of TOPO and 6.4 ml of oleylamine into the three-necked flask, continue After pas...

Embodiment 2

[0029] Weigh 0.1421 g of selenium powder and place it in a pear-shaped bottle, inject 2 ml of tributylphosphine (TBP) into the pear-shaped bottle in an anhydrous and oxygen-free glove box and seal it; take out the pear-shaped bottle from the glove box, and after ultrasonication Se powder can be dissolved to prepare TBPSe solution; weigh 0.018 g of cadmium ethyl xanthate and 0.1032 g of cadmium stearate into a 10 ml centrifuge tube, inject 1 ml of oleic acid into the centrifuge tube, and 1 ml of Oleylamine and 3 ml octadecene were ultrasonically obtained to obtain a cadmium precursor; weighed 0.077 g of CdO powder and placed it in a three-necked flask, and injected 1 ml of oleic acid (OA) and 8 ml of octadecene (ODE) into the three-necked flask , set up an anhydrous and oxygen-free system, pass through high-purity Ar (99.999%), heat the solution in the three-necked flask to 280°C after 30 min, and stop heating after the CdO is completely dissolved; take 1 g of TOPO and 6.4 ml of...

Embodiment 3

[0031] Weigh 0.1421 g of selenium powder and place it in a pear-shaped bottle, inject 2 ml of tributylphosphine (TBP) into the pear-shaped bottle in an anhydrous and oxygen-free glove box and seal it; take out the pear-shaped bottle from the glove box, and after ultrasonication Se powder can be dissolved to prepare TBPSe solution; weigh 0.036 g of cadmium ethyl xanthate and 0.2064 g of cadmium stearate into a 10 ml centrifuge tube, inject 2 ml of oleic acid into the centrifuge tube, and 3 ml of Oleylamine and 6 ml octadecene were ultrasonically obtained to obtain a cadmium precursor; weighed 0.077 g of CdO powder and placed it in a three-necked flask, and injected 1 ml of oleic acid (OA) and 8 ml of octadecene (ODE) into the three-necked flask In the process, set up an anhydrous and oxygen-free system, pass through high-purity Ar (99.999%), heat the solution in the there-necked flask to 280°C after 30 min, and stop heating after the CdO is completely dissolved; take 1 g of TOPO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com