Polypropylene/montmorillonite/graphite nanocomposite material and preparation method for same

A nanocomposite material and composite material technology are applied in the field of polypropylene/montmorillonite/graphite nanocomposite materials and their preparation, which can solve the problems of large molding shrinkage, insufficient rigidity, poor impact performance, etc., and achieve good electrical conductivity, The effect of simple preparation process and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

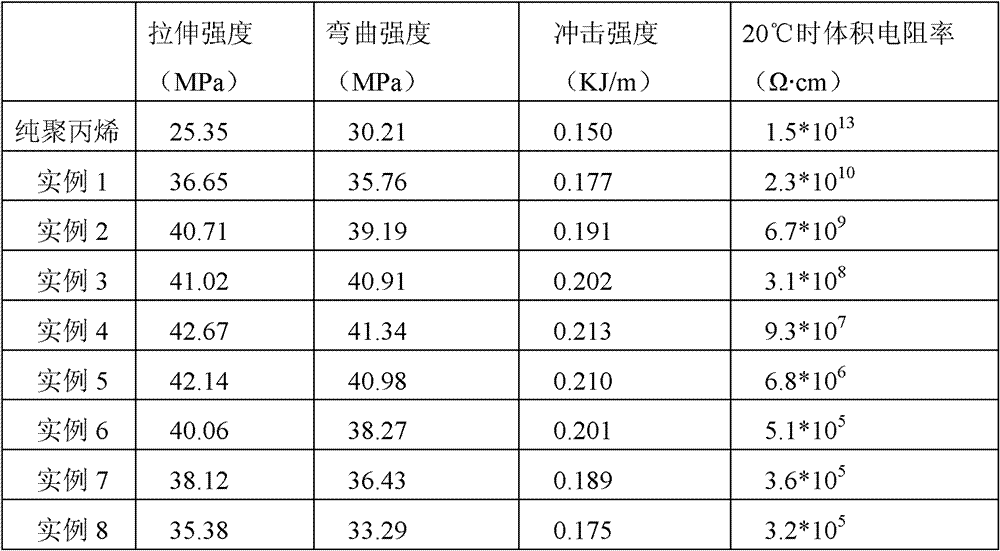

Embodiment 1

[0037] 5 parts of homopolypropylene (70% isotacticity, 150,000 molecular weight), 1 part of organically modified montmorillonite treated with cetyltrimethylammonium bromide, 0.1 part of maleic anhydride and 0.01 Parts of tert-butyl peroxide are pre-mixed in a high-speed mixer, the mixing time is 5-20min, extruded and granulated with a twin-screw extruder, and the extrusion temperature is 190-220°C to obtain a spare masterbatch; 95 parts of homopolypropylene (70% isotacticity, 150,000 molecular weight), 0.01 part of 2,6-tertiary butyl-4-methylphenol, 1 part of stearic acid, the masterbatch obtained in the above steps 1. 1 part of graphite with a particle size of 450 microns is mixed in a high-speed mixer, the mixing time is 5-20min, extruded with a twin-screw extruder, and the extrusion temperature is 200-230°C to obtain polypropylene / montmorillonite / Graphite nanocomposite material, its properties are shown in Table 1.

Embodiment 2

[0039] 10 parts of homopolypropylene (75% isotacticity, 200,000 molecular weight), 2 parts of cetyltrimethylammonium chloride-treated organically modified montmorillonite, 02 parts of maleic anhydride and 0.02 Parts of di-tert-butyl peroxide are pre-mixed in a high-speed mixer, the mixing time is 5-20min, extruded and granulated with a twin-screw extruder, and the extrusion temperature is 190-220°C to obtain a spare masterbatch; 90 parts of homopolypropylene (isotacticity is 75%, molecular weight is 200,000), 0.05 part of diphenylamine, 2 parts of calcium stearate, the masterbatch obtained in the above steps, 3 parts of graphite with a particle size of 470 microns at high speed Mix in a mixer, the mixing time is 5-20min, and extrude with a twin-screw extruder at an extrusion temperature of 200-230°C to obtain a polypropylene / montmorillonite / graphite nanocomposite material, whose properties are shown in Table 1.

Embodiment 3

[0041] 15 parts of homopolypropylene (80% isotacticity, 250,000 molecular weight), 3 parts of octadecyltrimethylammonium bromide processed organically modified montmorillonite, 0.3 part of maleic anhydride and 0.03 Parts of dicumyl peroxide are pre-mixed in a high-speed mixer, the mixing time is 5-20min, extruded and granulated with a twin-screw extruder, and the extrusion temperature is 190-220°C to obtain a spare masterbatch; then 85 1 part of homopolypropylene (80% isotacticity, 250,000 molecular weight), 0.1 part of 3,5-tertiary butyl-4-hydroxyphenyl sulfide, 3 parts of zinc stearate, the precursor obtained in the above steps granules and 5 parts of graphite with a particle size of 500 microns are mixed in a high-speed mixer, the mixing time is 5-20min, extruded with a twin-screw extruder, and the extrusion temperature is 200-230°C to obtain polypropylene / montmorillonite The properties of soil / graphite nanocomposites are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com