Preparation method of bismuth subcarbonate

A bismuth carbonate, basic technology, applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., can solve the problems of acid and alkali resistance, limited heavy metal adsorption capacity, and unsatisfactory selective adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

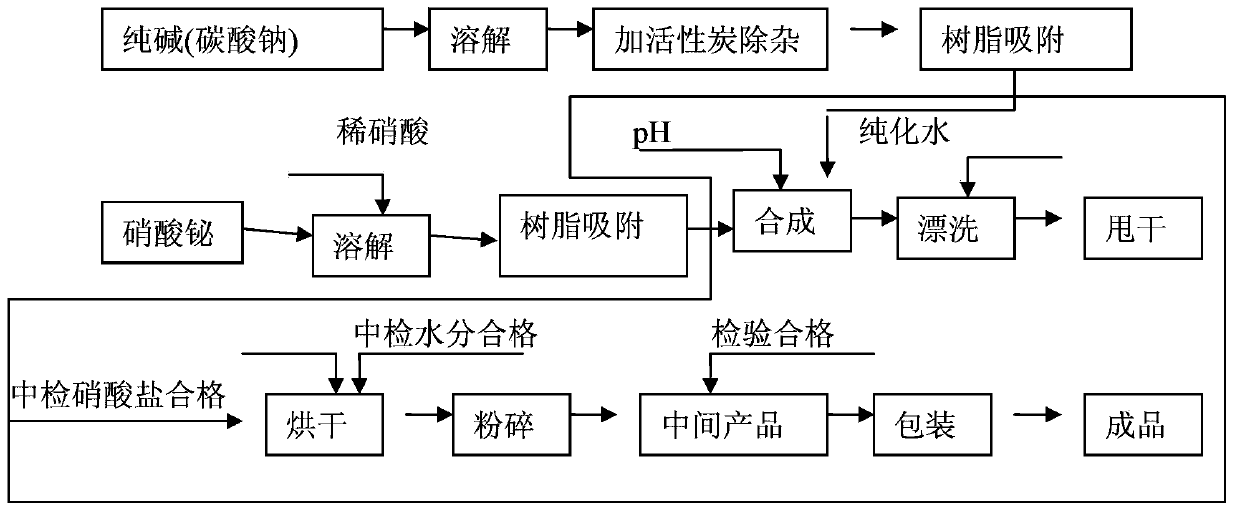

Method used

Image

Examples

preparation Embodiment 1

[0053] A) Preparation of polyacrylamide-co-styrene-co-acrylic acid copolymer (copolymer I, namely P(AM-St-AA))

[0054]83 g of monomeric acrylamide, 15 g of styrene and 2 g of acrylic acid were mixed to form 100 g of monomer mixture. Then add 20g of the above-mentioned monomer mixture in a glass reactor equipped with 500mL of deionized water, pass through nitrogen and carry out mechanical stirring, heat up to 55°C, add 0.5g of initiator potassium persulfate, and then proceed under stirring The polymerization was carried out for 1.5 hours to form a seed emulsion (ie, soap-free emulsion, self-emulsifying system). Then, the temperature of the seed emulsion is maintained at 55° C., the remaining 80 g of the monomer mixture is added dropwise to the seed emulsion and the time for adding is 3 hours, and the monomer mixture of 0.3 g will be formed while starting to drop the monomer mixture. The initiator solution formed by dissolving potassium sulfate in 5 ml of deionized water was s...

preparation Embodiment 2

[0060] The above example 1 was repeated, except that 0.2 g of crosslinking agent glutaraldehyde was added together with 20 g of formalin solution (35% concentration) in step B). A modified and slightly cross-linked polyacrylamide-co-styrene-co-acrylic acid copolymer (referred to as copolymer II-B) was obtained, and the weight average molecular weight measured by GPC method was 350,000. The content of mercapto (-SH) was determined to be 1.95wt% by purple spectrophotometry.

preparation Embodiment 3

[0062] Repeat the above Example 1, except that step B) does not add aminoethanethiol, and adds 8.5 g of dimethylamine. A modified polyacrylamide-co-styrene-co-acrylic acid copolymer (referred to as copolymer II-C) was obtained, and the weight average molecular weight measured by GPC method was about 130,000. The content of sulfhydryl (-SH) was determined to be 0wt% by purple spectrophotometry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com