Forging and molding process method for titanium alloy tubular piece

A titanium alloy tube and forging forming technology, which is applied in the field of tube forging and titanium alloy tube forging and forming technology, can solve the problem that the inner hole is prone to folded wrinkles, the high temperature strength of the titanium alloy, and the high price of the titanium alloy material. problems, to avoid folding wrinkles or even cracks, prevent grain coarsening, and reduce material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

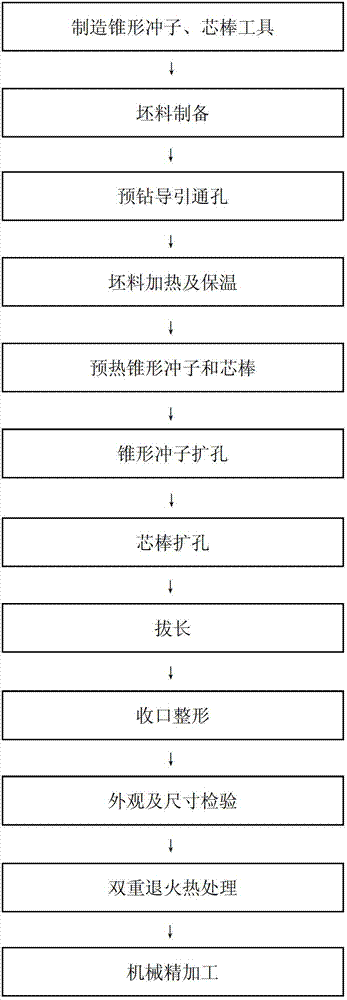

Image

Examples

Embodiment Construction

[0034] A kind of forging forming process method of titanium alloy tubular parts, it specifically comprises the following steps:

[0035] (1) Manufacture of tapered punches and mandrel tools

[0036] According to the processing size of TC9 or TC11 titanium alloy tubular parts, the tapered punch and mandrel tools for forging are pre-designed and manufactured.

[0037] (2) Blank preparation

[0038] According to the processing size of the tubular part, TC9 or TC11 titanium alloy bar is blanked to form a billet, the length-to-diameter ratio of the billet is 3-4, and the prepared billet has no crack defect.

[0039] (3) Pre-drilled pilot through holes

[0040] Axially pre-drill a guide through hole at the center of the side end face of the billet, the diameter of the guide through hole is 30% to 40% of the outer diameter of the billet, and the diameter of the guide through hole is smaller than the designed inner diameter of the tubular part.

[0041] (4) Blank heating and heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com