Welding technology for stainless steel composite tubes

A welding process, stainless steel technology, applied in the direction of welding equipment, manufacturing tools, workpiece edge, etc., can solve the problems that stainless steel cannot be realized, and achieve the effect of reducing corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

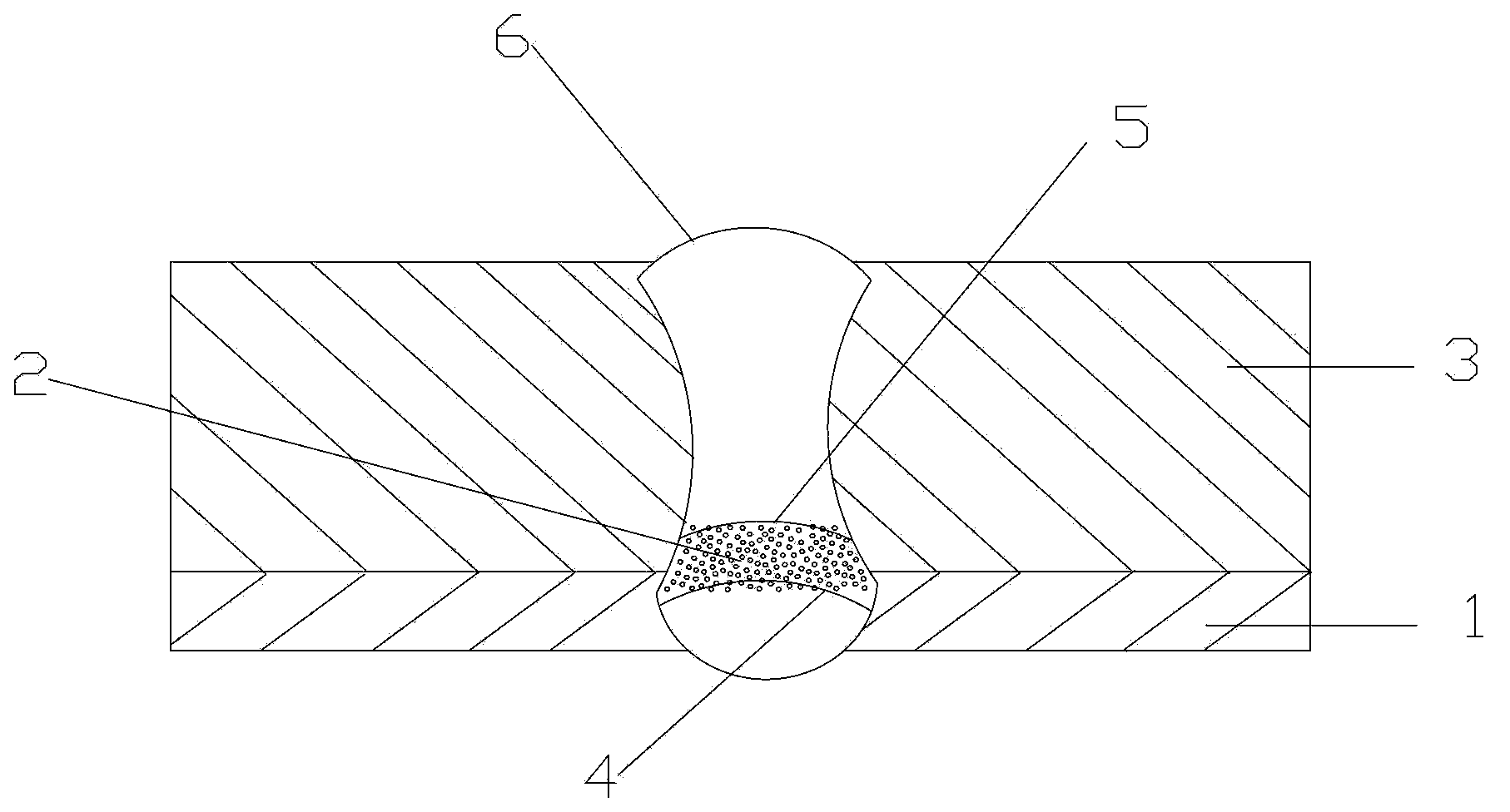

[0020] Such as figure 1 Shown, a stainless steel clad pipe welding process, comprises the following steps:

[0021] (1) Weld the cladding layer 1 of the stainless steel composite pipe to form a weld bead 4; the welding of the weld bead 4 should adopt TIG, MIG, and laser welding methods, which can ensure that the weld bead is free of dross and is conducive to the welding of the next weld bead .

[0022] (2) A transition layer 2 is welded between the cladding layer 1 and the base layer 3 of the stainless steel composite pipe to form a weld bead 25; the welding of the weld bead 25 should use electrodes with high chromium and nickel content, such as: A302, A307 , can reduce the impact on the cladding material when welding the base material.

[0023] (3) Weld the base layer 3 of the stainless steel composite pipe to form the third bead 6; the welding of the third bead 6 should adopt the submerged arc welding method, and the welding material can be the same material as the base ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com