Spray cooling device for centrifugal casting metal mold

A spray cooling and centrifugal casting technology, which is applied in the field of metallurgical centrifugal casting, can solve the problems of shortening the life of the mold and increasing the degree of chilling, and achieves the effect of uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

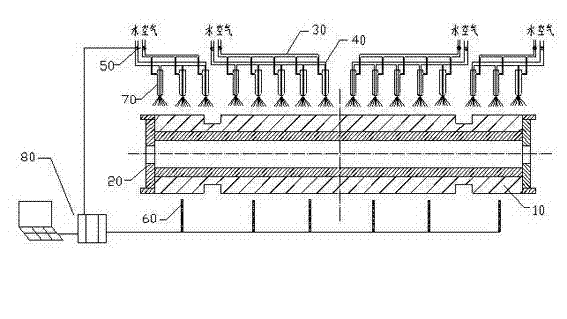

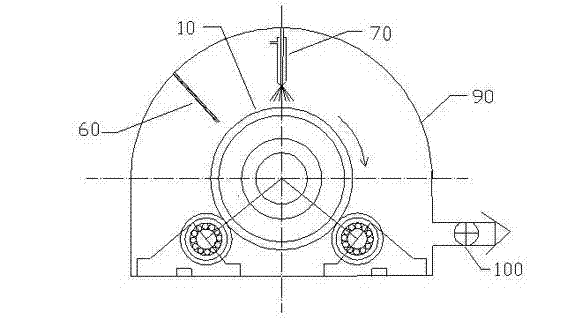

[0014] Such as figure 1 and figure 2 As shown, a centrifugal casting metal mold spray cooling device is composed of an automatic temperature monitoring feedback system and spray equipment, and is provided with a mold cylinder 10, an end cover 20, a gas collection pipe 30, a water collection pipe 40, a solenoid valve 50, an infrared probe 60, and a mist Nozzle 70, temperature sensor 80, steam guide cover 90, induced draft fan 100, the temperature automatic monitoring feedback system of this cooling device includes infrared probe 60 and temperature sensor 80, spraying equipment includes air collecting pipe 30, water collecting pipe 40, electromagnetic valve 50 And the atomizing nozzle 70, the atomizing nozzle 70 is set in a double-channel annulus, the water goes through the inner channel, and the air goes through the outer channel, and the atomization is realized at the outlet by adjusting the flow ratio of water and gas.

[0015] The tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com