Fibrous hydrogel and preparation method thereof

A hydrogel and fiber technology, applied in the field of medical materials and their preparation, can solve the problems of complex preparation steps, toxicity, inconvenience in use and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

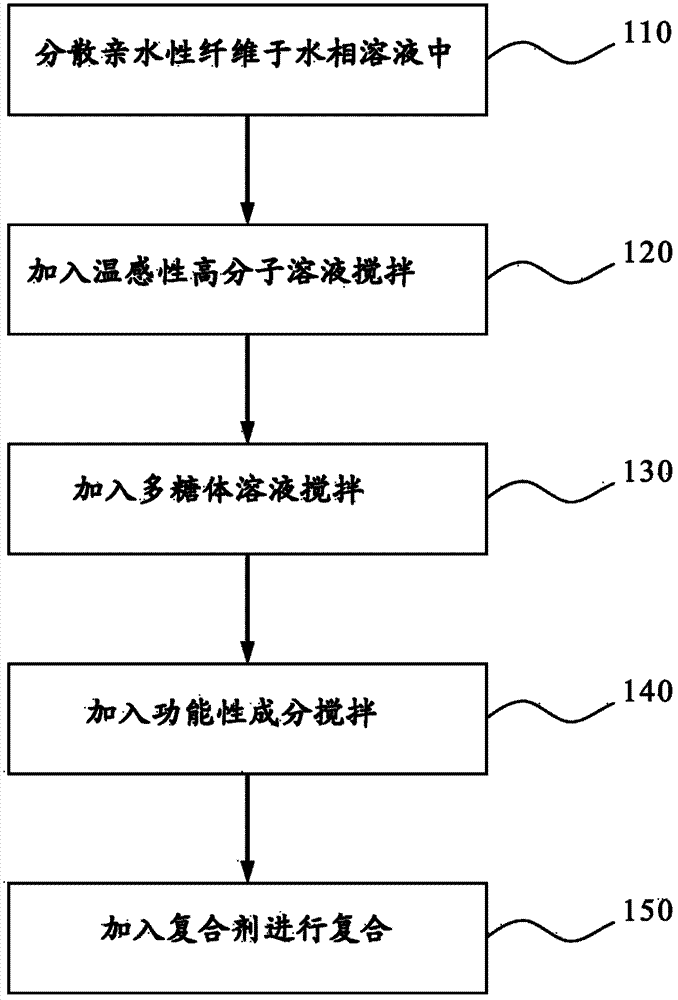

[0027] 【Preparation method of fiber hydrogel】

[0028] The preparation method of the above-mentioned fiber hydrogel comprises the following steps: preparing hydrophilic fibers, stirring and dispersing them in the aqueous phase solution, preparing a temperature-sensitive polymer solution, preparing a polysaccharide solution, and dissolving them in the hydrophilic fiber dispersion according to Add temperature-sensitive polymer solution, polysaccharide solution, and functional ingredients in sequence to form a hydrogel solution, and then slowly add a compounding agent while stirring to form a fiber-shaped hydrogel.

[0029] refer to figure 1 , which is a flow chart of the manufacturing method of fiber hydrogel. exist figure 1 Among them, the manufacturing method of the above-mentioned fiber hydrogel includes dispersing hydrophilic fibers in the water phase (step 110), adding a temperature-sensitive polymer solution (step 120), adding a polysaccharide solution (step 130), adding...

Embodiment 1

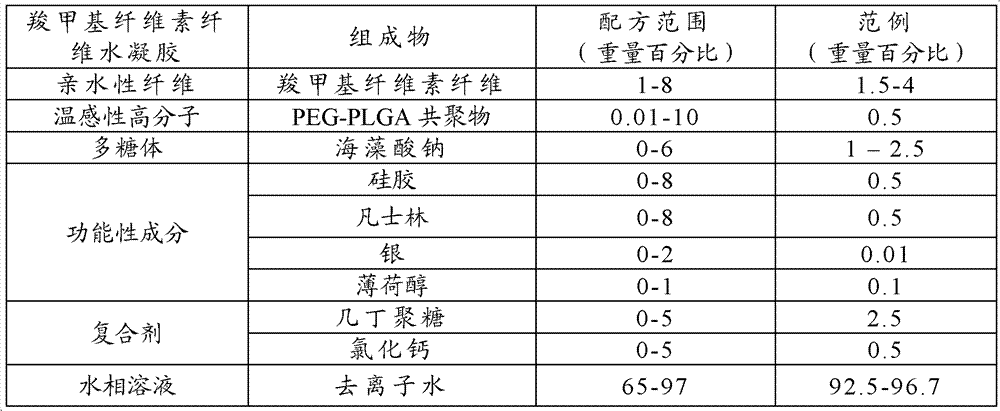

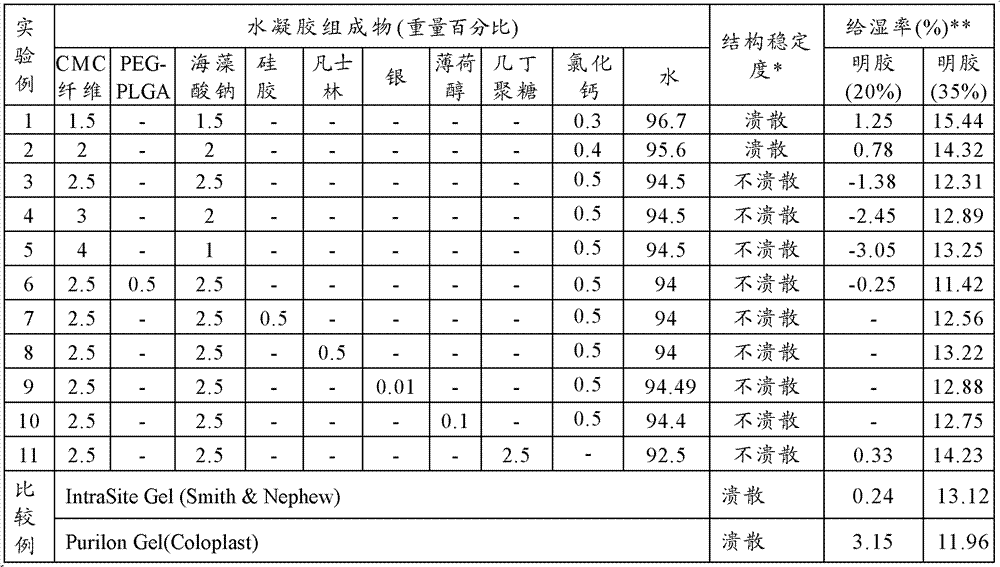

[0033] Embodiment one: various fiber hydrogels of carboxymethyl cellulose fibers

[0034] Firstly, for the preparation of carboxymethyl cellulose fibers, for example, reference can be made to the method disclosed in WO93 / 12275 "Cellulosic Fibers". The main methods are as follows. Firstly, the cotton fiber (Tencell or Lyocell fiber) is soaked in alkali solution (mixed solution of 40% NaOH and 95% EtOH, volume ratio 2:3) and reacted for 2 hours. Then react in an organic solvent solution of chloroacetic acid or sodium chloroacetate (mixture of 40% NaOH and 95% EtOH, volume ratio 2:3) for 20 hours to etherify to obtain sodium carboxymethyl cellulose Salt. Then, wash with 70-95% alcohol for several times, and dry in an oven at 65°C for 48 hours to obtain carboxymethyl cellulose fibers. In the aforementioned etherification reaction, factors such as the amount of chloroacetic acid or sodium chloroacetate, reaction temperature, and reaction time can be adjusted to regulate the hydr...

Embodiment 2

[0046] Example 2: Various fiber hydrogels of alginate fibers

[0047] In embodiment two, the alginate fibers used are all made by wet spinning, the spinning solution of wet spinning is 5wt% sodium alginate, and the forming solution is 5wt% calcium chloride (the solvent is a volume ratio of 1:1 alcohol and water). The diameter of the alginate fiber is 10-20 μm, and the fiber diameter and length of the alginate fiber can be 0.1-500 μm and 0.1 μm-10 cm, respectively, for example, 1-50 μm and 0.1 mm-5 cm, respectively.

[0048] Next, the production method of the alginate fiber hydrogel will be described. Take an appropriate amount of alginate fibers with a diameter and length of 12 μm and 0.1 mm-5 cm, respectively, add an appropriate amount of water phase solution and stir, so that the alginate fibers are dispersed in the water phase solution. Next, as in Example 1, add an appropriate amount of thermosensitive polymer solution at a temperature lower than the thermosensitive poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com