Method for extracting grape seed oil by cold pressing

A grape seed oil, grape seed technology, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problem that the cell wall cannot be destroyed, and achieve less loss of nutrients, full utilization, and high oil yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

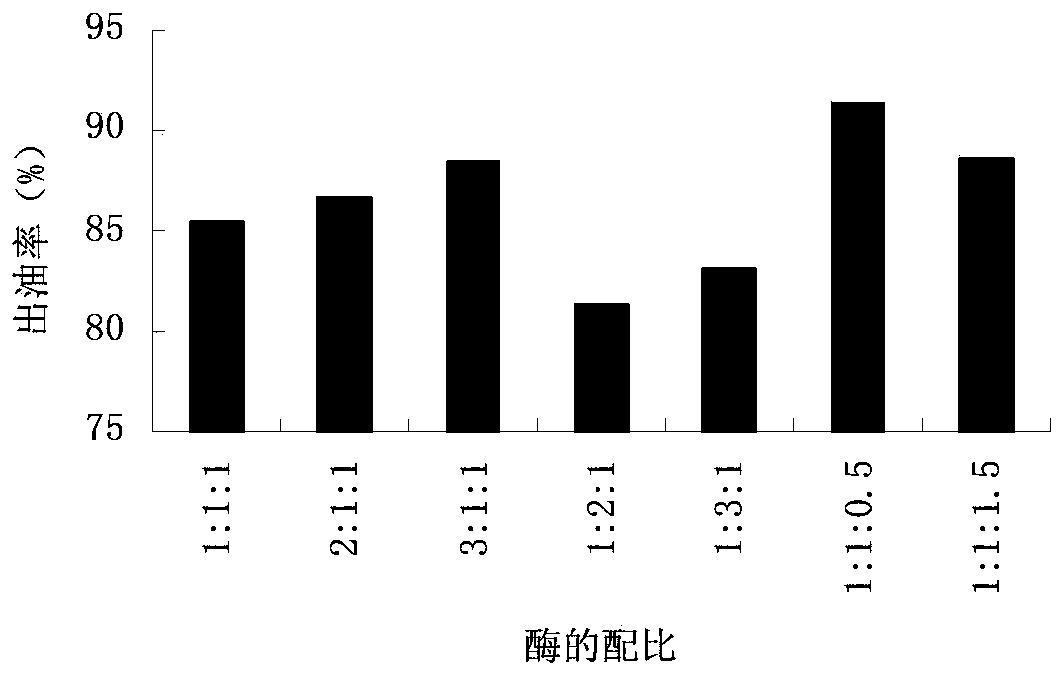

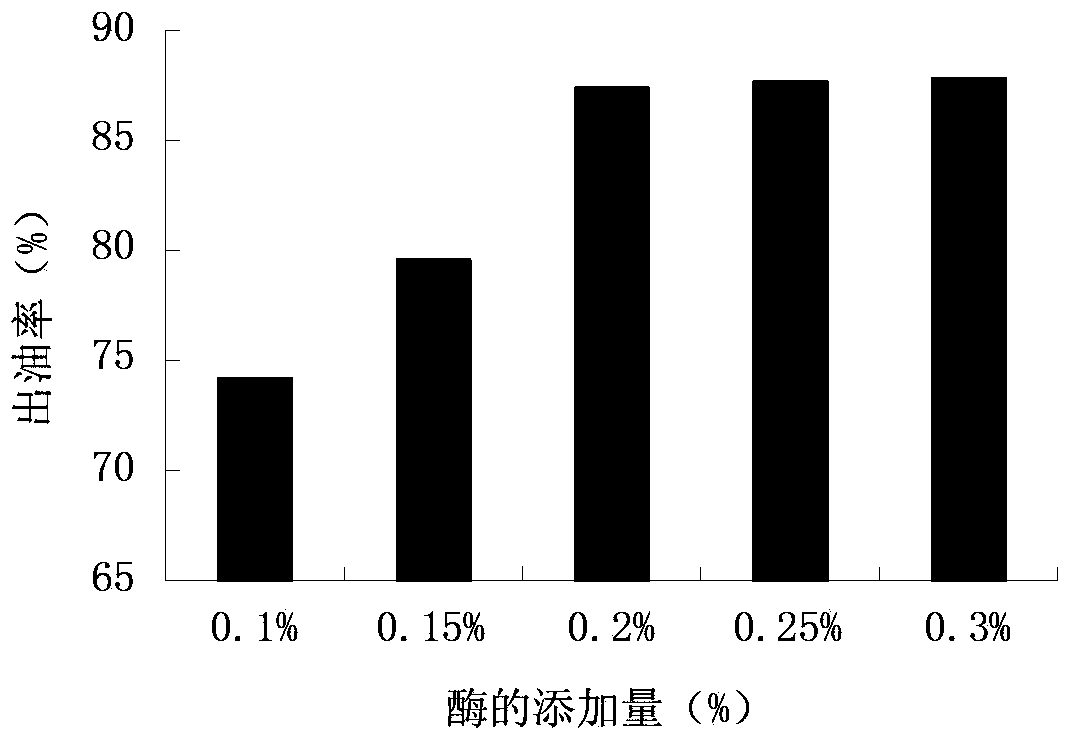

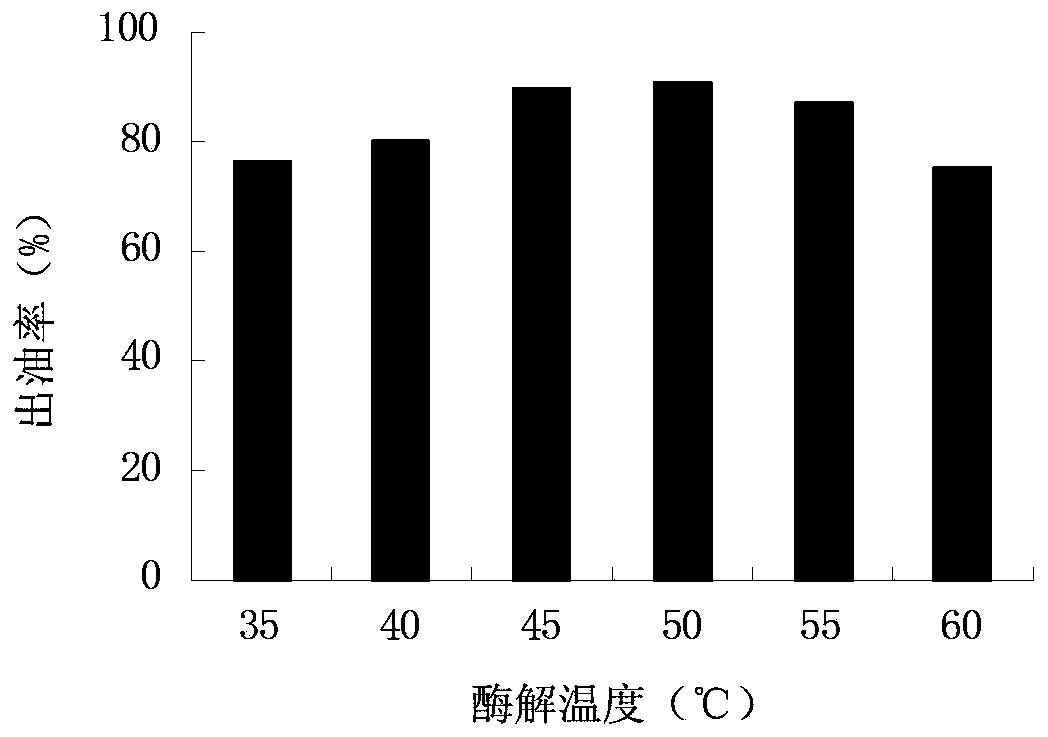

[0045] Effects of enzyme pretreatment on grape seed cold pressing oil extraction process:

[0046] 1. Materials and methods:

[0047] 1.1 Raw materials and reagents:

[0048] Grape seeds: provided by Shihezi Tiancheng Oil Co., Ltd. Pectinase (10,000U / g activity), cellulase (10,000U / g activity), and neutral protease (50,000U / g activity) were all purchased from Beijing Aobo Biotechnology Co., Ltd.

[0049] 1.2 Instruments and equipment:

[0050] PHS-2C acidity meter, Shanghai Precision Scientific Instrument Co., Ltd.; DGG-9053AD electric heating constant temperature drying oven, Shanghai Senxin Experimental Instrument Co., Ltd.; MLS-3020 high-pressure steam boiler, SANYO; LXJ-I-IB centrifuge, Shanghai Anting Technology Instrument Factory; HH-4 digital display constant temperature water bath, Guohua Electric Co., Ltd. 2. Experimental method:

[0051] 2.1 Pretreatment of grape seeds:

[0052] Use winnowing and vibrating sieves to remove the grape seeds that have deteriorated...

Embodiment 2

[0113] Optimization of grape seed cold pressing oil production process:

[0114] 1. Experimental materials and methods:

[0115] Grape seed raw materials were provided by Shihezi Tiancheng Oil Co., Ltd. The experimental equipment is shown in Table 5.

[0116] table 5

[0117]

[0118] 2. Experimental method:

[0119] 2.1 Pretreatment of grape seeds

[0120] Use winnowing and vibrating sieves to remove the grape seeds that have deteriorated, shrunken shells, and broken skins, and then soak them in clean water to remove the juice mucus on the surface. Put them in a cool and ventilated place to dry naturally, seal them well, and store them in a cool, dark place for later use.

[0121] 2.2 Tablets

[0122] The cleaned and removed grape seeds are pressed into tablets using a double-roller flaking machine, and the thickness of the grape seed blanks is required to reach 0.6-1.0mm.

[0123] 2.3 Wetting

[0124] The moisture content of the grape seed flakes is adjusted to 20%...

Embodiment 3

[0172] Pilot study:

[0173] In October 2012, a pilot test was carried out at Shihezi Tiancheng Oil Co., Ltd. by enzymatic hydrolysis-cold pressing technology, and about 20 tons of grape seed oil were produced. The product is light yellow-green, clear, transparent, good smell and taste, moisture and volatile matter 0.01%, impurity 0.03%, soap content 0.004%, acid value 0.21mg / g, peroxide value 1.3mmol / kg, lead 0.02mg / kg, aflatoxin B1<10ug / kg, copper 0.01mg / kg, iron 0.02mg / kg, fenthion and dimethoate were not detected, and all indicators of the product reached the national standard of "Grape Seed Oil" (GB / T22478 -2008).

[0174] Process flow: Grape seed→cleaning and impurity removal→water regulation→flaking→enzymolysis→water and temperature regulation→pressing→refining→filling→storage.

[0175] Operation points:

[0176] (1) Cleaning and removing impurities: the grape seed raw materials are cleaned through winnowing and screening, and the impurity content is required to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com