Oil-displacement surfactant composition, preparation method and application

A technology of surfactants and compositions, applied in the field of surfactant compositions for oil displacement, can solve problems such as damage, poor oil displacement efficiency, corrosion equipment and pipeline emulsification difficulty, and achieve improved oil displacement efficiency and interfacial activity High, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

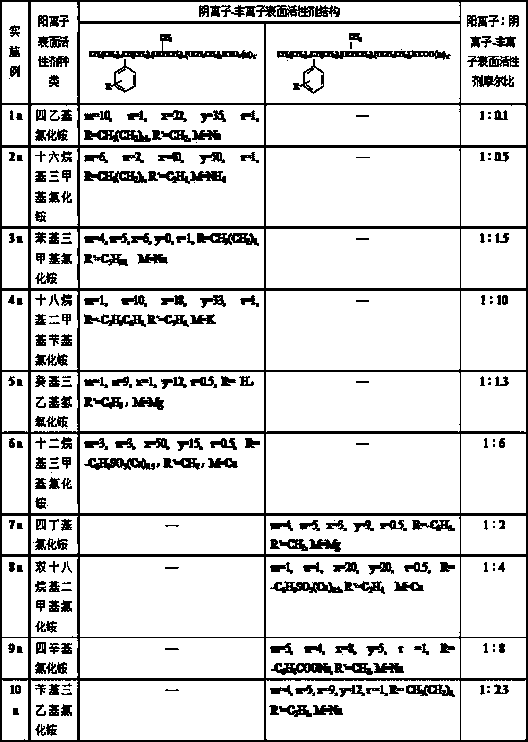

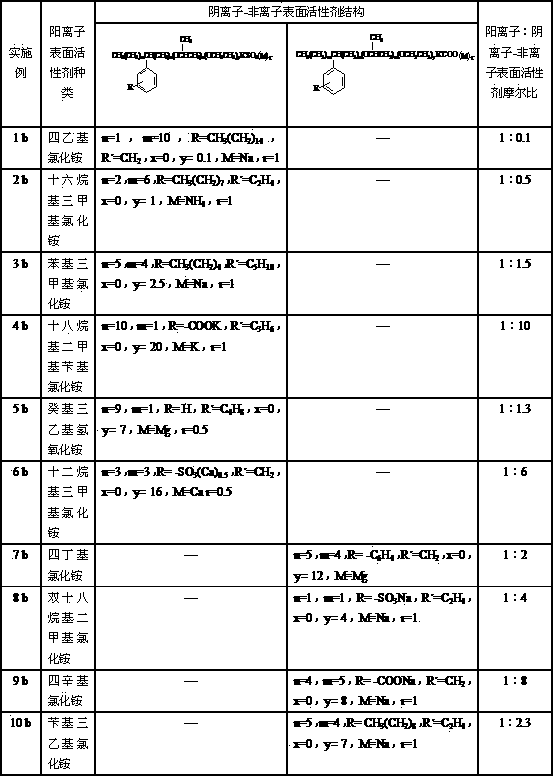

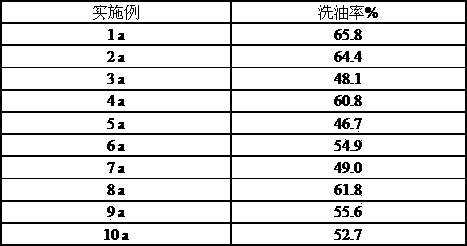

Examples

Embodiment 1a

[0029] CH 3 (CH 2 ) 10 CH=CHCOOH, pentadecylbenzene and perchloric acid are added to the reaction kettle, and N 2 to a pressure of 35kg / cm 2 , at 200 o C reacted for 2 hours, wherein CH 3 (CH 2 ) 10 CH=CHCOOH: pentadecylbenzene: perchloric acid molar ratio is 1:1:0.1. After the reaction finishes, add the Pd / C catalyst of fatty acid weight 1%, at 100 o C. 100kg / cm 2 Pressure hydrogenation reaction for 10 hours, and then filter out the Pd / C catalyst; add the aryl-substituted aliphatic alcohol and NaOH obtained in the previous steps into the reactor at a molar ratio of 1:1.5, stir for 30 minutes and then add the required propylene oxide, at 150 o C reaction 5 hours; Then add the required amount of oxirane, at 200 o C was reacted for 1 hour to obtain aryl-substituted fatty alcohol polyoxypropylene polyoxyethylene ether; then according to polyether: ClCH 2 SO 3 Na molar ratio 1:3, add sulfonation reagent, heat up to 70 o C was reacted for 10 hours. After the reaction...

Embodiment 2

[0033] CH 3 (CH 2 ) 6 CH=CHCOOH, Octylbenzene and ClSO 3 H is added to the reactor, and N 2 Up to a pressure of 100kg / cm 2 , at 50 o C reacted for 20 hours, wherein CH 3 (CH 2 ) 6 CH=CHCOOH: Octylbenzene: ClSO 3 The H molar ratio is 1:1:0.25. After the reaction finishes, add the Pd / C catalyst of fatty acid weight 0.2%, at 120 o C. 120kg / cm 2 Pressure hydrogenation reaction for 8 hours, and then filter out the Pd / C catalyst; add the aryl-substituted aliphatic alcohol and KOH obtained in the previous steps according to the molar ratio of 1:1.5 into the reactor, stir for 30 minutes, then add the required propylene oxide, and then 120 o C reaction 7 hours; Then add the required amount of oxirane, at 160 o C reacted for 4 hours to obtain aryl-substituted fatty alcohol polyoxypropylene polyoxyethylene ether; then add sulfonating reagent according to polyether:sodium isethionate molar ratio 1:2.5, and heat up to 90 o C was reacted for 8 hours. After the reaction, neutr...

Embodiment 3

[0037] CH 3 (CH 2 ) 4 CH=CH(CH 2 ) 3 COOH, pentylbenzene and p-toluenesulfonic acid are added to the reaction kettle, and N 2 Up to a pressure of 100kg / cm 2 , at 50 o C reacted for 20 hours, wherein CH 3 (CH 2 ) 4 CH=CH(CH 2 ) 3 The molar ratio of COOH:amylbenzene:toluenesulfonic acid is 1:1:0.25. After the reaction finishes, add the Pt / C catalyst of fatty acid weight 0.2%, at 300 o C. 100kg / cm 2 Pressure hydrogenation reaction for 1 hour, and then filter out the Pt / C catalyst; add the aryl-substituted aliphatic alcohol and CsOH obtained in the previous steps into the reaction kettle according to the molar ratio of 1:1.5, stir for 30 minutes, then add the required propylene oxide, and then 100 o C reaction 20 hours; Then add the required amount of oxirane, at 200 o C was reacted for 1 hour to obtain aryl-substituted fatty alcohol polyoxypropylene polyoxyethylene ether; then according to the molar ratio of polyether: sodium hydroxyamylsulfonate 1:4, add sulfonati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com