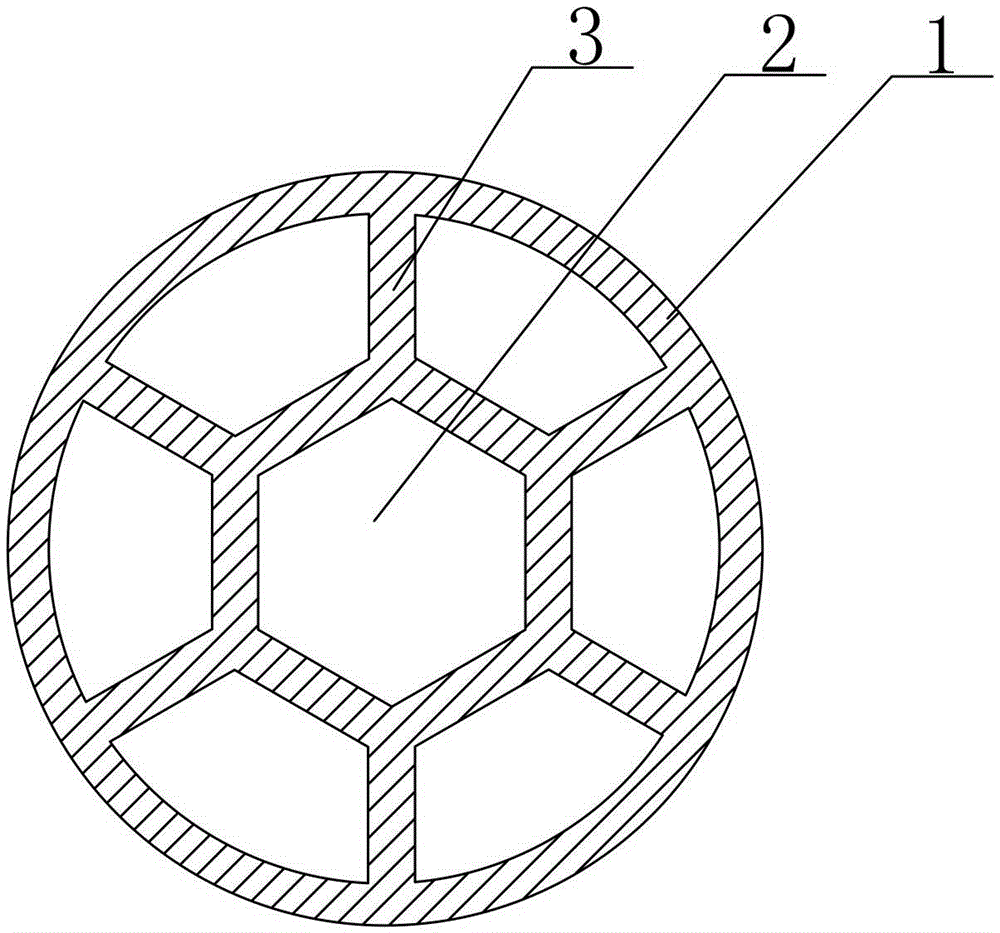

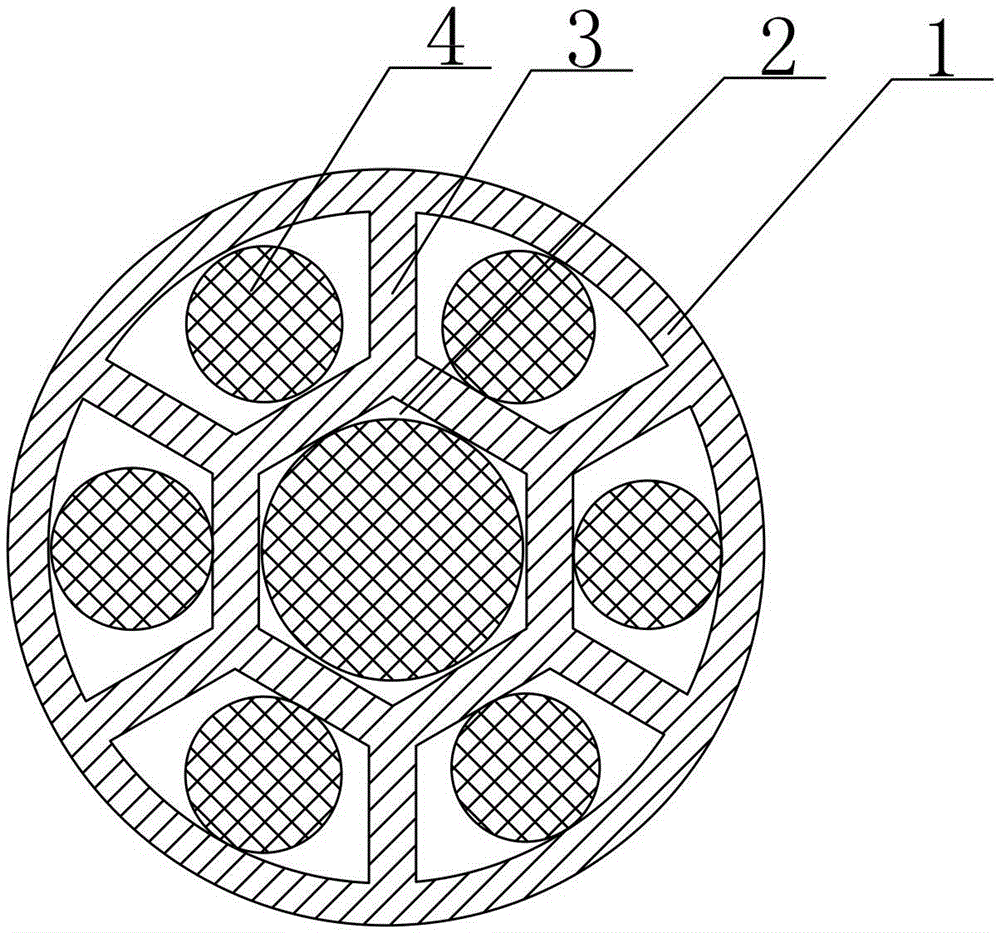

A wear-resistant and impact-resistant porous cable protection pipe and its preparation method

A technology for protecting pipes and cables, which is applied in the field of wear-resistant and impact-resistant porous cable protection pipes and their preparation. It can solve the problems of limiting the use efficiency of cable pipes, PVC pipes are easy to freeze and crack, and lag behind, so as to improve the function and use Efficiency, high impact strength, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Get 100 parts of polyvinyl chloride resin; 5 parts of composite impact modifiers; 3 parts of molybdenum disulfide powder of 30 microns; 10 parts of alumina powder of 100 nanometers; 0.2 parts of aminosilane; 0.5 parts of antioxidant 1010; 0.5 parts of didecyl adipate; 0.5 parts of zinc stearate; 2 parts of color masterbatch according to the weight ratio, put the component raw materials into a high-speed mixer for blending, the speed is 500 rpm, and the stirring temperature is 50 ℃, stirred and mixed for 5 minutes, and then molded by a twin-screw extruder.

[0020] The composite impact modifier is a mixture of polyethylene and ethylene-octene copolymer with a molecular weight of 2 million to 8 million and a diameter of 1 to 10 microns in a weight ratio of 1:1, which is crushed after banburying at 150°C for 5 minutes made.

[0021] The barrel temperature of the extruder is 170°C in the first zone; 175°C in the second zone; 180°C in the third zone; 185°C in the fourth zon...

Embodiment 2

[0023] Get 100 parts of polyvinyl chloride resin; 3 parts of composite impact modifier; 2 parts of graphite powder of 20 microns; 10 parts of boron nitride powder of 100 nanometers; 0.3 parts of octylsilane; 0.5 parts of antioxidant 1010; 0.5 parts of didecyl adipate; 0.5 parts of zinc stearate; 3 parts of color masterbatch according to the proportion by weight. Put the component raw materials into a high-speed mixer for blending in turn, the speed is 500 rpm, and the stirring temperature is 50 ℃, stirred and mixed for 5 minutes, and then molded by a twin-screw extruder.

[0024] The composite impact modifier is obtained by mixing acrylonitrile-butadiene-styrene copolymer and ethylene-vinyl acetate copolymer at a weight ratio of 1:1, banburying at 150°C for 5 minutes, and then crushing. The technical parameters of the ethylene-vinyl acetate copolymer are melt index ≤ 5g / 10min, ASTMD-1238, 100°C, 1.2kg; VA content 50wt%, Mooney viscosity ML1+4, 27±4 at 100°C, Density 1.00g / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com