Method for acknowledging rebound value of rebound instrument

A rebound rebound meter and rebound value technology, which is applied in the direction of testing the hardness of materials, etc., can solve the problems that the energy of the object to be tested cannot be directly and accurately reflected, and the accuracy is not high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Attached below figure 2 The specific implementation and theoretical basis of the method for confirming the rebound value of the rebound hammer involved in the present invention will be further described in detail.

[0030] A method for confirming the rebound value of a rebound hammer, which includes the following steps:

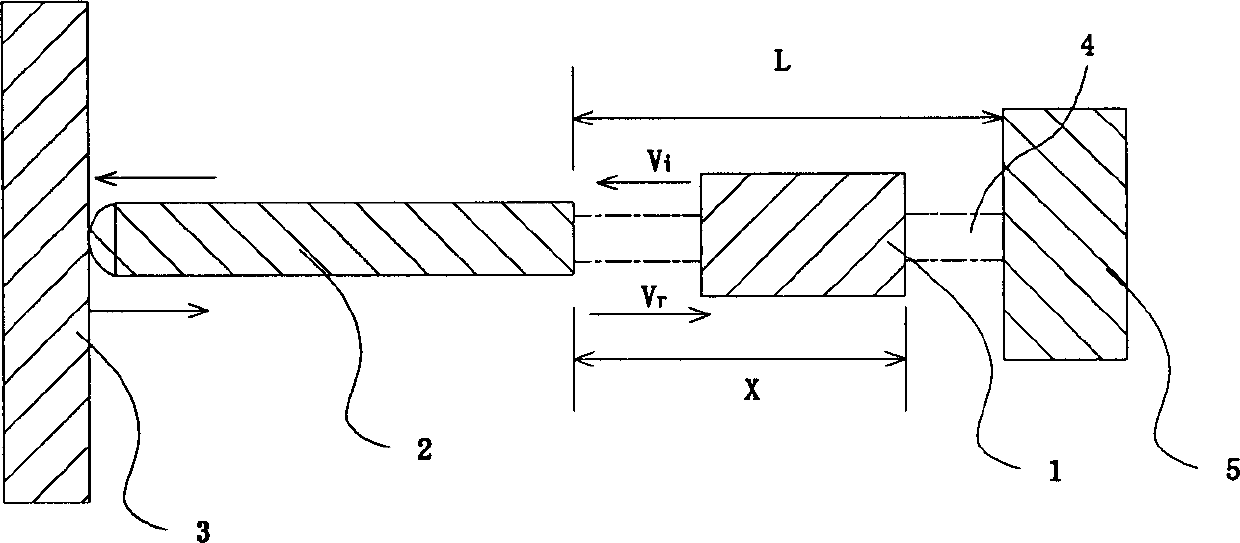

[0031] 1) Use a spring to drive the bouncing hammer 1 to strike the bouncing rod 2, and the bouncing rod 2 will collide with the object under test 3 after being hit;

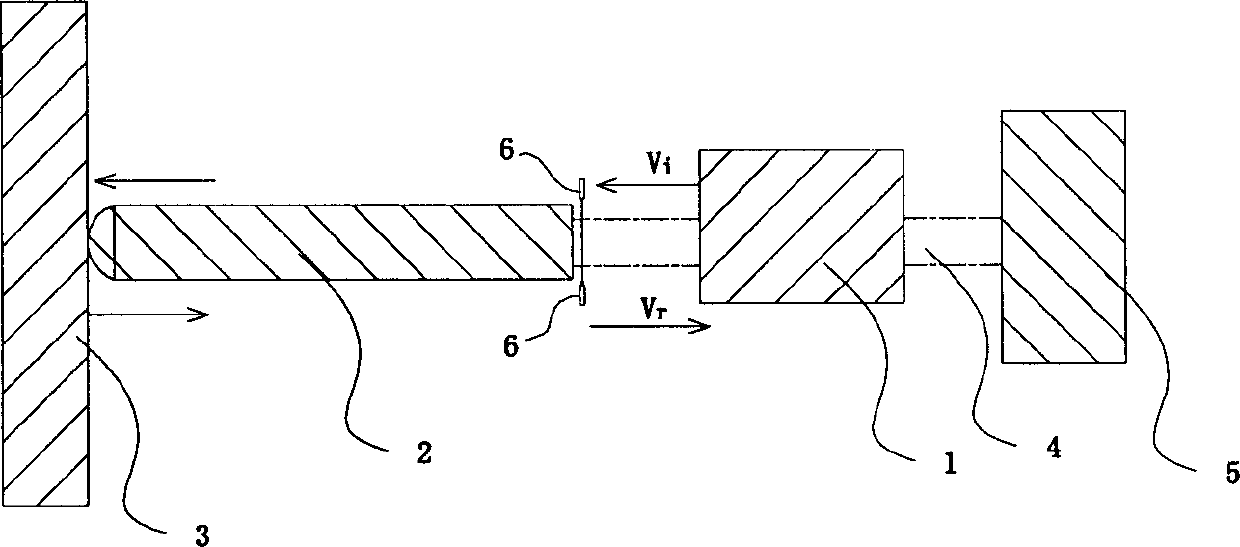

[0032] 2) Use the sensor 6 to measure and read the impact velocity Vi of the impact hammer 1 when it hits the impact bar 2;

[0033] 3) Use the sensor 6 to measure and read the rebound velocity Vr of the bouncing hammer after the bouncing hammer 1 hits the bouncing rod 2;

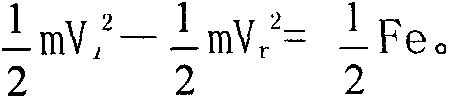

[0034] 4) The value obtained by dividing the rebound velocity Vr by the impact velocity Vi is used as the rebound value of the rebound hammer.

[0035] In step 1), driving the spring hammer 1 and impacting the obj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com