Soil dynamic test device

A test device and soil technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve the problems of heavy workload, inaccurate test results, high cost, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

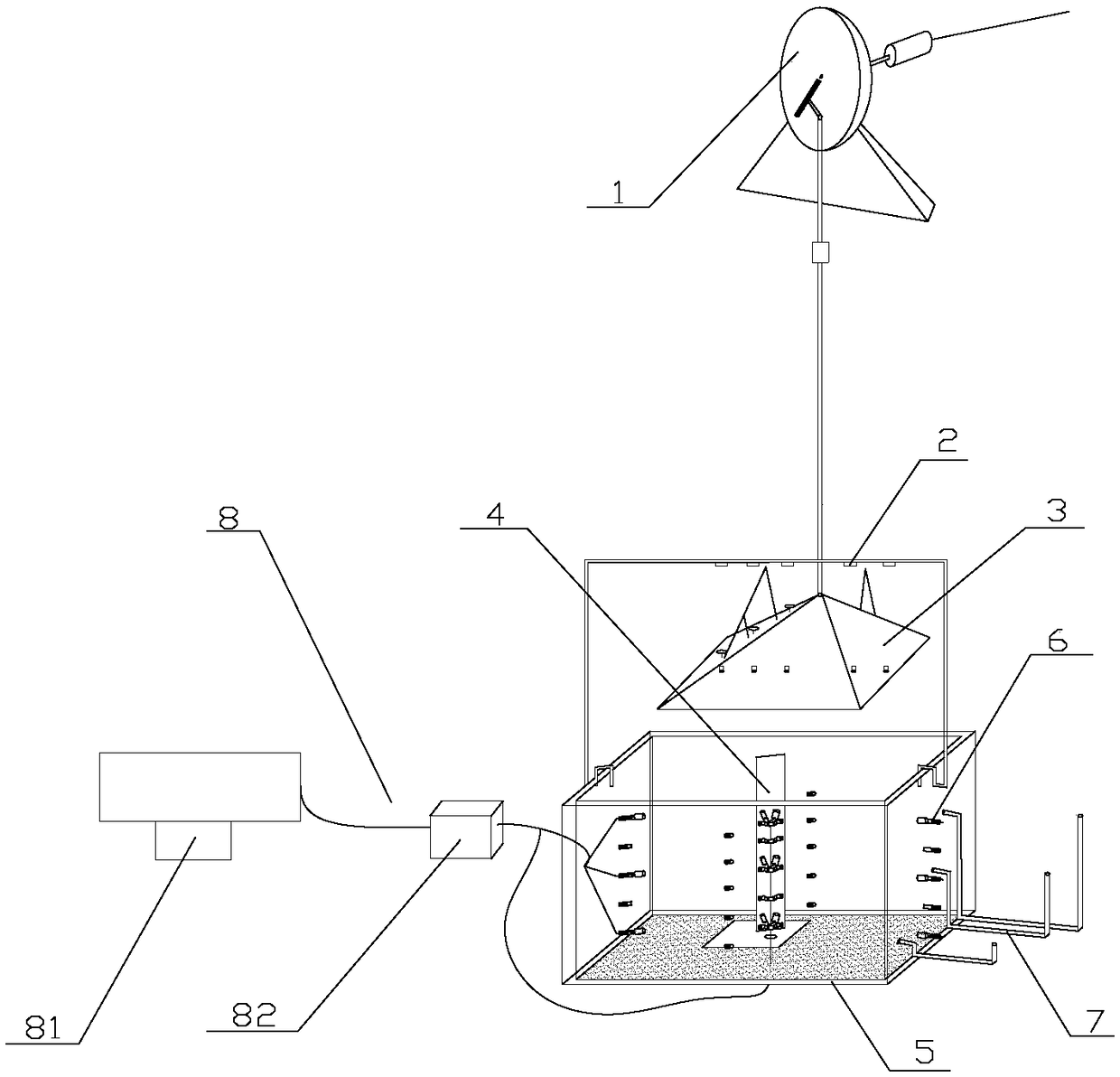

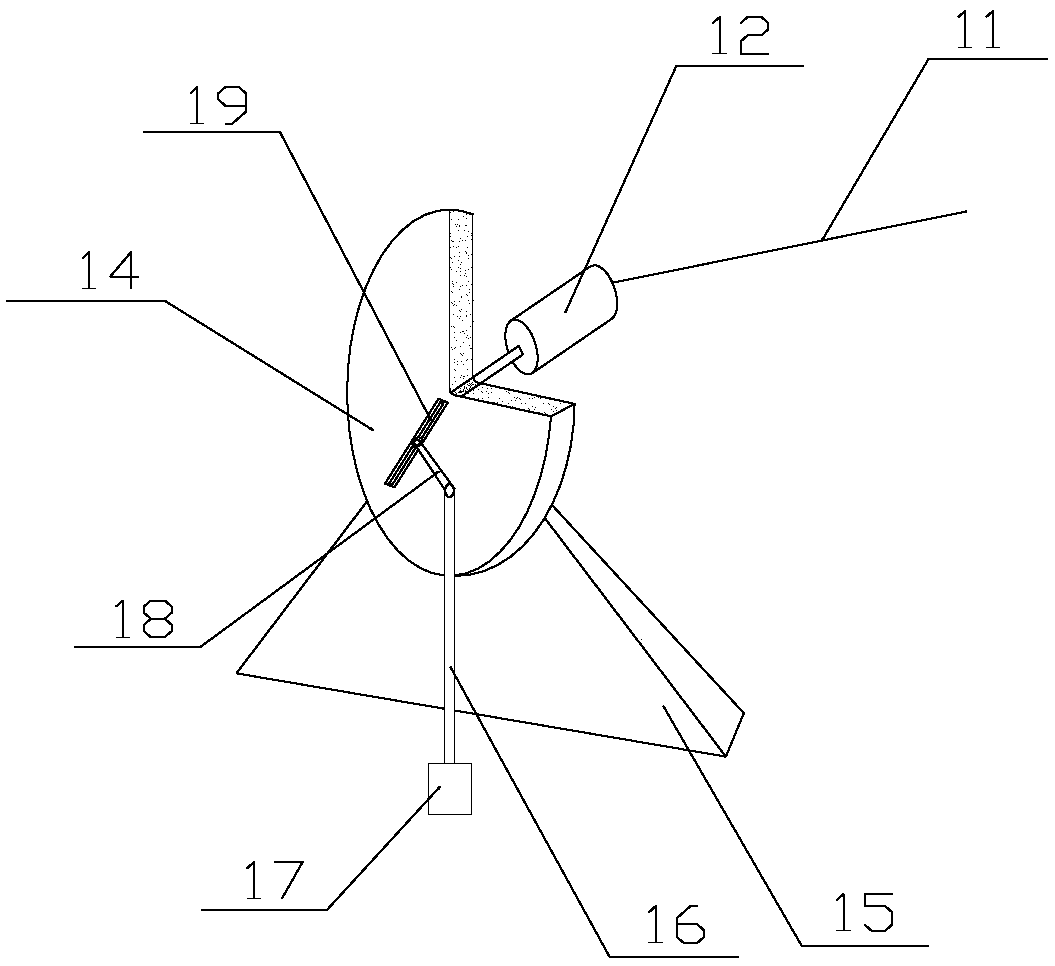

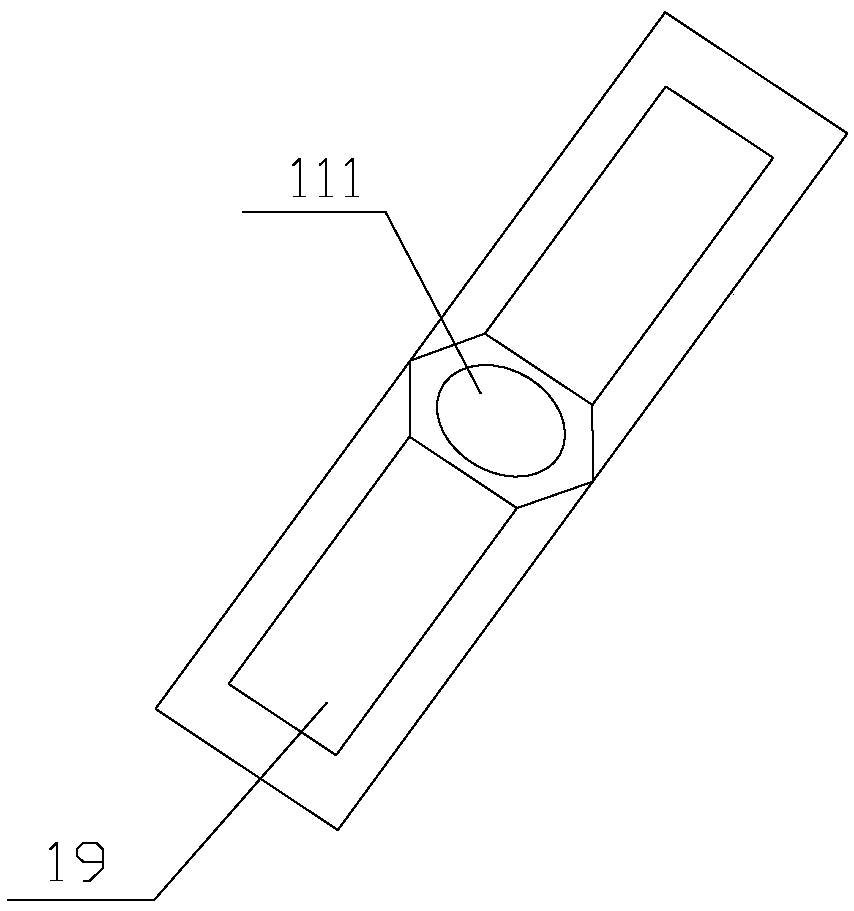

[0036] See attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Figure 6 , attached Figure 7 , attached Figure 8 , attached Figure 9 And attached Figure 10 , the present invention comprises a test box 5, the bottom of the test box 5 is paved with soil, the inside of the test box 5 is filled with seawater, and the test box 5 is provided with a pressure measuring mechanism 6 for testing the inner soil pressure and pore pressure, The top of the test box 5 is connected with a loading plate mechanism 3; the loading plate mechanism 3 is connected with a cyclic power mechanism 1 that drives it to reciprocate linearly along the vertical direction, and the loading plate mechanism 3 is also connected with a displacement device for detecting its motion displacement Measuring mechanism 2, pressure measuring mechanism 6 is connected with computer control mechanism 8, and displacement measuring mechanism 2 is also conne...

Embodiment 2

[0042] See attached Figure 11 In this embodiment, on the basis of Embodiment 1, the loading plate 31 is set to a conical shape, and the test box 5 is set to a cylindrical shape. On the bottom plate body of the loading plate 31, five first pressure probes are arranged along its diameter direction 24. On the cone of the loading plate 31, five reflective plates 23 on the same straight line as the first pressure probe 24 are arranged along the two symmetrical hypotenuses thereof; at the same time, on the top support 22 of the test box 5 Five displacement sensors 21 are set, and the positions of the displacement sensor 21, the reflection plate 23 and the first pressure probe 24 correspond one by one. The stress of the soil body was measured, and the strain states at these five different positions were measured, and the one-to-one correspondence between the stress and strain states of the soil at different positions on the same plane was realized.

[0043] See attached Figure 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com