Method for separating titanium, iron, vanadium and calcium from mixed titaniferous slag

A technology for separating iron and slag, applied in the field of metallurgy, can solve the problems of wasting energy, high cost, environmental pollution, etc., and achieve the effects of high efficiency, energy saving, low production cost, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

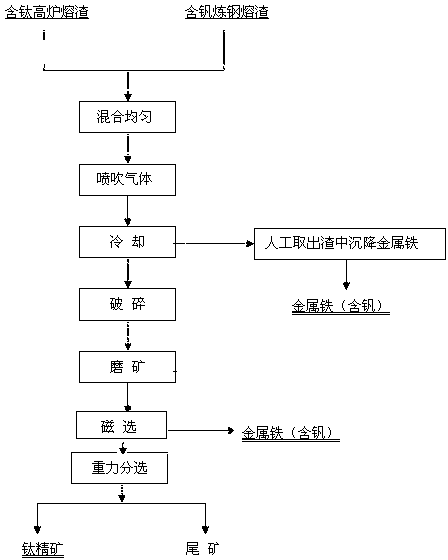

Method used

Image

Examples

Embodiment 1

[0070] Fully mix 100kg of titanium-containing blast furnace slag and 3kg of vanadium-containing steel slag flowing out of the slag outlet to form a mixed slag;

[0071] The chemical composition of titanium-containing blast furnace slag is: 25.52wt%TiO 2, 20.69wt%CaO, 7.90wt%MgO, 11.95wt%Al 2 o 3 , 3.20wt% FeO and 17.80wt% SiO 2 , the balance is other impurities;

[0072] The chemical composition of vanadium-containing steel slag is: V 2 o 5 3.17wt%, TFe18.60wt%, 41.73wt%CaO, 11.65wt%SiO 2 , 5.37wt%TiO 2 , 2.60wt%MgO, 1.24wt%MnO, 1.22wt%Al 2 o 3 , the balance is other impurities;

[0073] Inject oxygen into the mixed melt for 25 minutes, the flow rate of oxygen is 1L / (min kg), after the gas injection is completed, the slag is naturally cooled;

[0074] From the cooled slag, manually remove the vanadium-containing metallic iron that settled to the bottom in the slag, crush the remaining slag to a particle size of 20-250 μm, grind the ore, and separate the remaining van...

Embodiment 2

[0078] Fully mix 100kg of titanium-containing blast furnace slag and 500kg of vanadium-containing steel slag flowing out of the slag outlet to form a mixed slag;

[0079] The chemical composition of titanium-containing blast furnace slag is: 23.01wt%TiO 2 , 20.68wt%CaO, 8.52wt%MgO, 12.58wt%Al 2 o 3 , 3.83wt%FeO, and 18.44wt%SiO 2 , the balance is other impurities;

[0080] The chemical composition of vanadium-containing steel slag is: V 2 o 5 2.12wt%, TFe19.55wt%, 40.83wt%CaO, 12.62wt%SiO 2 , 4.40wt%TiO 2 , 3.60wt%MgO, 1.20wt%MnO, 1.26wt%Al 2 o 3 , the balance is other impurities;

[0081] Inject air into the mixed melt for 2 minutes, the flow rate of air is 110L / (min kg), after the gas injection is completed, the slag is naturally cooled;

[0082] From the cooled slag, manually remove the vanadium-containing metallic iron that settled to the bottom in the slag, crush the remaining slag to a particle size of 20-250 μm, grind the ore, and separate the remaining vanadi...

Embodiment 3

[0084] Fully mix 300kg of titanium-containing blast furnace slag and 35kg of vanadium-containing steel slag flowing out of the slag outlet to form a mixed slag;

[0085] The chemical composition of titanium-containing blast furnace slag is: 22.30wt%TiO 2 , 19.89wt%CaO, 8.92wt%MgO, 12.98wt%Al 2 o 3 , 4.23wt%FeO, and 18.74wt%SiO 2 , the balance is other impurities;

[0086] The chemical composition of vanadium-containing steel slag is: V 2 o 5 1.13wt%, TFe17.64wt%, 43.71wt%CaO, 12.63wt%SiO 2 , 4.41wt%TiO 2 , 3.64wt%MgO, 1.00wt%MnO, 1.42wt%Al 2 o 3 , the balance is other impurities;

[0087] Inject oxygen into the mixed melt for 6 minutes, the flow rate of oxygen is 50L / (min kg), after the end of gas injection, the slag is naturally cooled;

[0088] From the cooled slag, the vanadium-containing metal iron that settled to the bottom in the slag is manually removed, the remaining slag is crushed to a particle size of 20-250 μm, the ore is ground, and the remaining vanadiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com