Middle coating paint for polypropylene plastic and preparation method thereof

A technology of polypropylene plastic and chlorinated polypropylene, applied in the direction of coating, etc., can solve the problems of automobile damage, inability to withstand the damage of ethanol gasoline, etc., and achieve the effects of low cost, improved storage stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

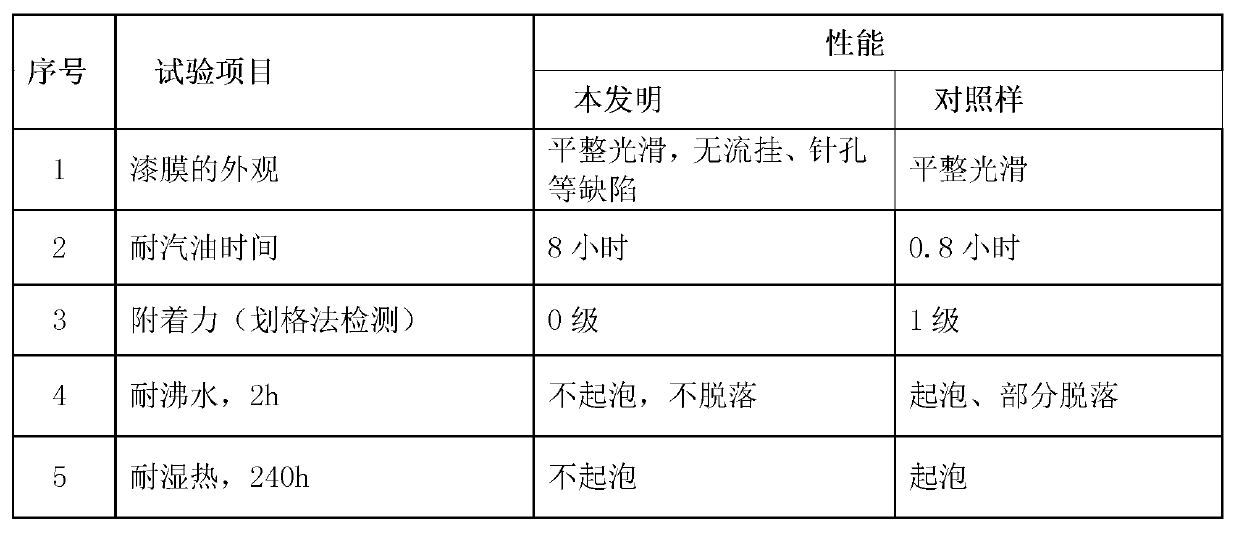

Examples

Embodiment 1

[0040] A kind of raw material (by weight percentage) of intermediate coating coating for polypropylene plastics is as follows:

[0041] Chlorinated polypropylene modified acrylic resin: 35%,

[0042] Modified chlorinated polypropylene: 20%,

[0043] Diphenolic propane type epoxy resin: 1%,

[0044] Titanium dioxide: 15%,

[0046] Fumed silica: 1%,

[0047] Styrene-maleic anhydride copolymer: 0.1%,

[0048] Xylene fill up to 100%.

[0049] Preparation method: weigh according to the above ratio, mix chlorinated polypropylene modified acrylic resin, titanium dioxide, talcum powder, fumed silica, styrene-maleic anhydride copolymer, and xylene; then mix the materials together Put it into a sand mill for uniform dispersion; then add modified chlorinated polypropylene and diphenolic propane epoxy resin to it and mix evenly to make a coating.

Embodiment 2

[0051] A kind of raw material (by weight percentage) of intermediate coating coating for polypropylene plastics is as follows:

[0052] Chlorinated polypropylene modified acrylic resin: 20%,

[0053] Modified chlorinated polypropylene: 35%,

[0054] Diphenolic propane type epoxy resin: 2%,

[0055] Iron yellow: 10%,

[0058] Polyethylene wax: 0.5%,

[0059] Styrene-maleic anhydride copolymer: 0.2%,

[0060] Cyclohexanone: 15%,

[0061] Propylene glycol makes up to 100%.

[0062] Preparation method: weigh according to the above ratio, mix chlorinated polypropylene modified acrylic resin, iron yellow, talcum powder, barium sulfate, polyethylene wax, styrene-maleic anhydride copolymer, cyclohexanone, and propylene glycol ; Then put the materials together into a sand mill for uniform dispersion; then add modified chlorinated polypropylene and diphenolic propane epoxy resin to it and mix evenly to make a coating.

Embodiment 3

[0064] A kind of raw material (by weight percentage) of intermediate coating coating for polypropylene plastics is as follows:

[0065] Chlorinated polypropylene modified acrylic resin: 30%,

[0066] Modified chlorinated polypropylene: 30%,

[0067] Novolak epoxy resin: 1.5%,

[0068] Kaolin: 10%,

[0070] Styrene-maleic anhydride copolymer: 0.1%,

[0071] Methyl isoamyl ketone: 10%,

[0072] Fill toluene to 100%;

[0073] Preparation method: weigh according to the above ratio, mix chlorinated polypropylene modified acrylic resin, kaolin, polyamide wax, styrene-maleic anhydride copolymer, methyl isoamyl ketone, and toluene; then mix Put the materials together into the sand mill for uniform dispersion; then add modified chlorinated polypropylene and phenolic polyepoxy resin to it and mix evenly to make the coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com