Environment-friendly ethanol migration resistance elastomer sheathing compound and preparation method thereof

A technology of ethanol resistance and sheath material, which is applied in the direction of conductors, insulated conductors, plastic/resin/wax insulators, etc., can solve the problems of poor ethanol migration resistance, hard sheath material, and poor processability, and achieve excellent ethanol resistance Migration performance, dry effect of discharged powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

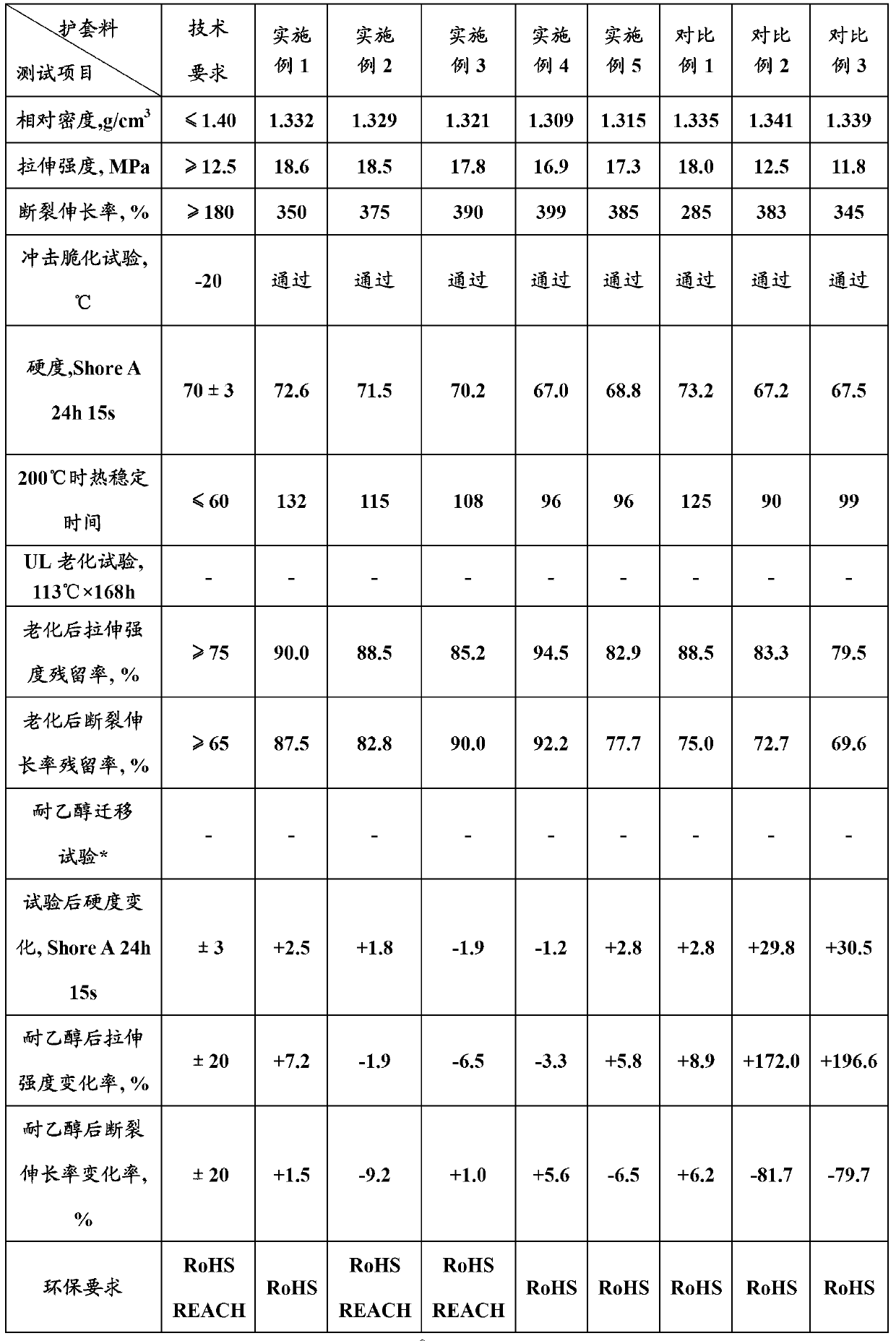

Examples

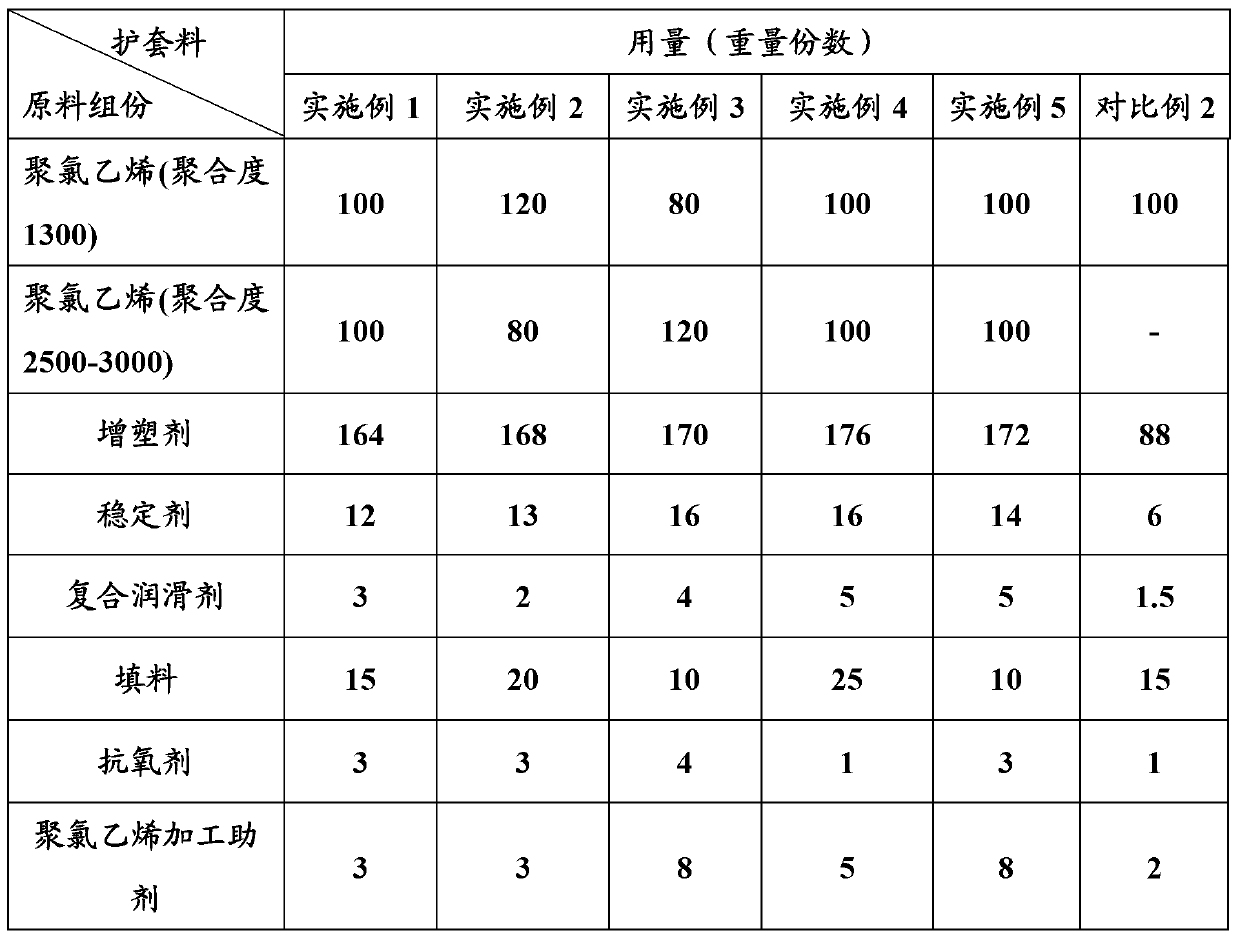

Embodiment 1

[0030] This example provides a kind of environment-friendly type anti-ethanol migration resistant elastomeric sheath material, its raw material formula sees Table 1, wherein: plasticizer is polyester plasticizer and epoxidized soybean oil by weight ratio 1.6:1 composition; Stabilizer is Calcium-zinc composite stabilizer; composite lubricant is composed of paraffin wax and oxidized polyethylene wax in a weight ratio of 1:1.2; filler is activated calcium carbonate; antioxidant is phenolic antioxidant; polyvinyl chloride processing aid is ACR-201 .

[0031] The preparation method of the environment-friendly alcohol migration-resistant elastomer sheath material is as follows:

[0032] (1) Add the high-polymerization degree polyvinyl chloride resin powder, the stabilizer, the antioxidant, and the plasticizer of 1 / 2 the formula into the low-speed kneader in sequence, and control the temperature as follows: At about 20±2°C, the stirring speed is 20 rpm, and the stirring speed is con...

Embodiment 2

[0036] This example provides an environment-friendly ethanol migration-resistant elastomer sheath material, and its raw material formula is shown in Table 1, wherein: the plasticizer is composed of polyester plasticizer and epoxy soybean oil in a weight ratio of 5:1; the stabilizer is Calcium-zinc composite stabilizer; composite lubricant is composed of paraffin wax and oxidized polyethylene wax in a weight ratio of 1:0.8; filler is talc powder; antioxidant is amine antioxidant; polyvinyl chloride processing aid is ACR-401.

[0037] The preparation method of the environment-friendly alcohol migration-resistant elastomer sheath material is as follows:

[0038] (1) Add the high-polymerization degree polyvinyl chloride resin powder, the stabilizer, the antioxidant, and 1 / 3 of the plasticizer into the low-speed kneader in sequence, and control the temperature at Between 20°C and 30°C, stir at a speed of 30 rpm, and stir at a constant speed for about 5 minutes to obtain a mixture; ...

Embodiment 3

[0042] This example provides an environmentally friendly ethanol migration-resistant elastomer sheath material. The raw material formula is shown in Table 1, wherein: the plasticizer is composed of polyester plasticizer and DOS in a weight ratio of 10:1; the stabilizer is calcium-zinc composite Stabilizer; composite lubricant is composed of paraffin wax and polyethylene wax in a weight ratio of 1:2; filler is talc powder; antioxidant is amine antioxidant; polyvinyl chloride processing aid is ACR-401.

[0043] The preparation method of the environment-friendly alcohol migration-resistant elastomer sheath material is as follows:

[0044] (1) Add the high-polymerization degree polyvinyl chloride resin powder, the stabilizer, the antioxidant, and 1 / 3 of the plasticizer into the low-speed kneader in sequence, and control the temperature at Between 20°C and 30°C, the stirring speed is 25 rpm, and the stirring speed is constant for about 5 minutes to obtain the mixture;

[0045] (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com