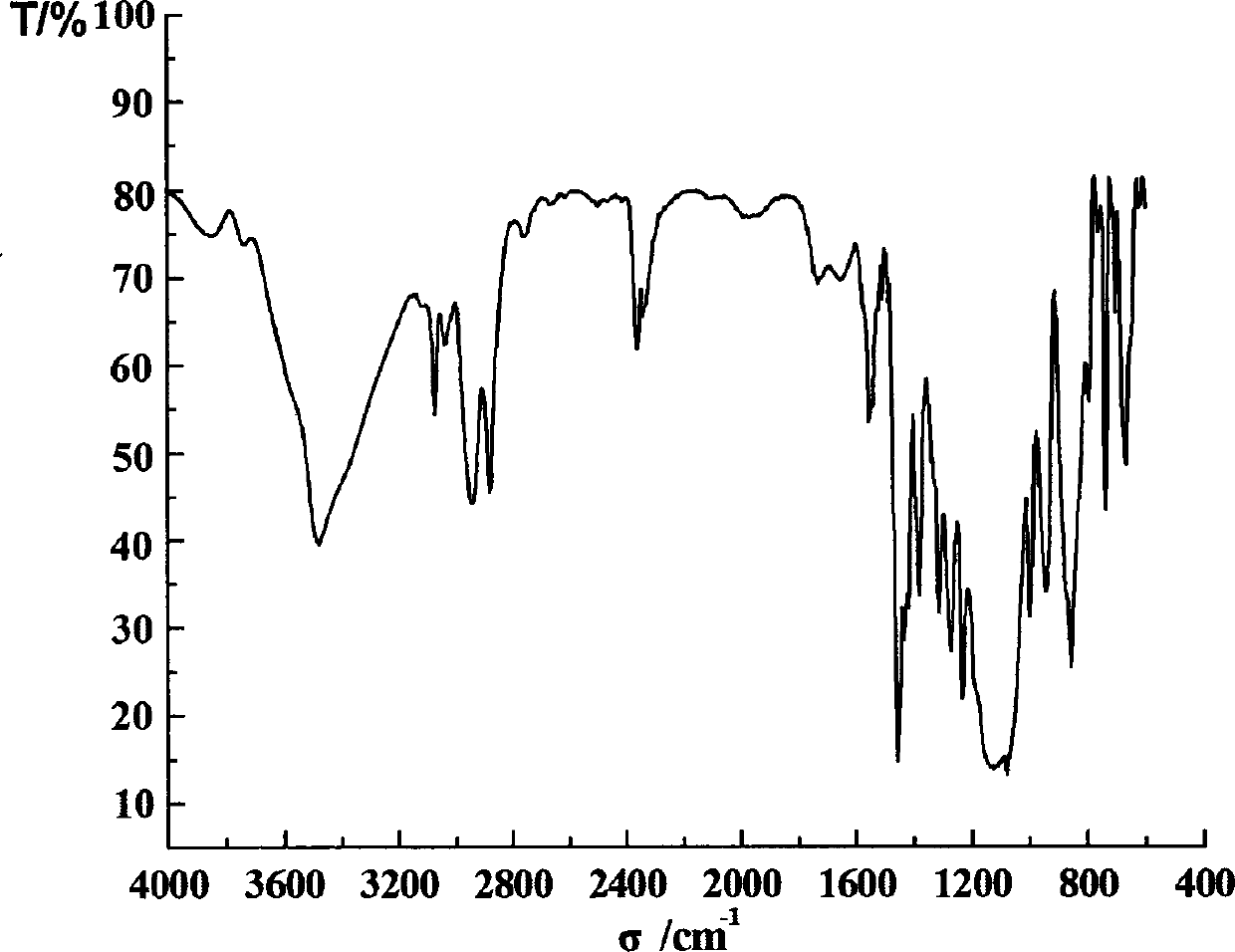

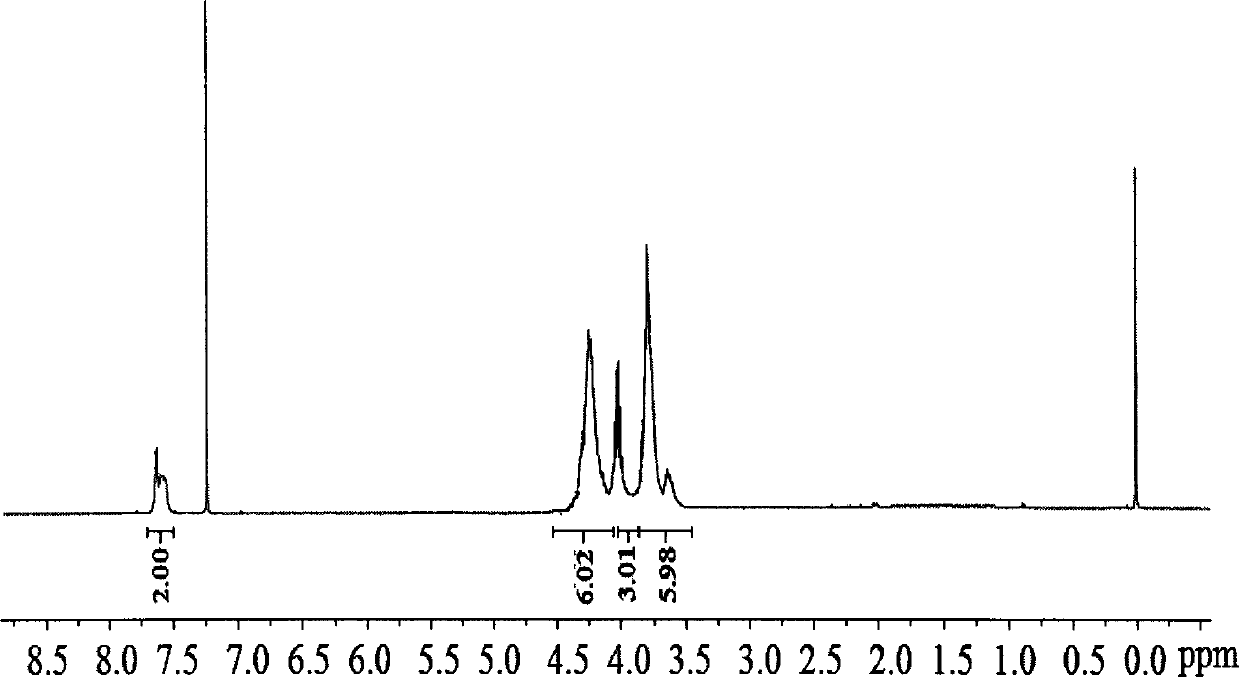

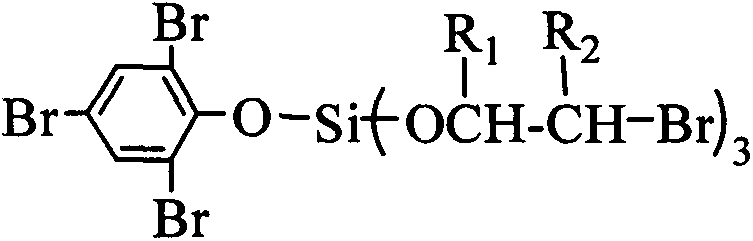

Flame retardant tri(dibromopropyl)tribromophenyl silicate esterification compound and preparation method thereof

A technology of dibromopropyl and tribromophenyl esters, which is applied in the direction of silicon organic compounds, can solve the problem that the by-product silicon tetrachloride cannot be processed, and achieve good application and development prospects, low production costs, and stable physical and chemical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]Example 1 In the 500ml four-necked flask equipped with agitator, thermometer, dropping funnel and high-efficiency reflux condenser and a hydrogen chloride absorbing device connected in series with a drying tube at the top of the condenser, replace the air in the bottle with nitrogen , add 100ml of dioxane and 16.99g (0.1mol) of silicon tetrachloride, under stirring, cool with an ice-water bath, reduce the temperature of the reaction system to 0°C, and drop 21.79g of silicon tetrachloride into the organic solution (0.1mol) 2,3-dibromo-1-propanol, the temperature of the dropwise addition process is controlled below 8°C, after the drop is completed, the temperature is raised to 35°C in 1h, and the heat preservation reaction is carried out for 1h. After the hydrogen chloride is released, add 33.08g ( 0.1mol) of tribromophenol, raised the temperature to 80°C, and kept the temperature for 2 hours. Acceleration control temperature does not exceed 50°C. After dripping, raise the...

Embodiment 2

[0032] Example 2 In a 500ml four-necked flask equipped with a stirrer, a thermometer, a dropping funnel and a high-efficiency reflux condenser and a hydrogen chloride absorbing device connected in series with a drying tube at the top of the condenser, replace the air in the bottle with nitrogen , add 100ml of ethylene glycol dimethyl ether and 16.99g (0.1mol) of silicon tetrachloride, under stirring, cool with an ice-water bath, reduce the temperature of the reaction system to 0°C, and add dropwise to the organic solution of silicon tetrachloride 21.79g (0.1mol) 2,3-dibromo-1-propanol, the dropwise addition process controls the temperature below 8°C, after the drop is completed, the temperature is raised to 35°C for 1h, and the temperature is kept for 1h. After the hydrogen chloride is released, add 33.08 g (0.1mol) tribromophenol, heat up to 60°C, keep warm for 4 hours, after the hydrogen chloride is released, cool down to below 40°C, then add 43.58g (0.2mol) 2,3-dibromo-1-pro...

Embodiment 3

[0033] Example 3 In a 500ml four-neck flask equipped with a stirrer, a thermometer, a dropping funnel and a high-efficiency reflux condenser and a hydrogen chloride absorbing device connected in series with a drying tube at the top of the condenser, replace the air in the bottle with nitrogen , add 100ml acetonitrile and 16.99g (0.1mol) silicon tetrachloride, under stirring, cool with ice-water bath, make reaction system temperature drop to 0 ℃, dropwise add 21.79g (0.1mol) in the organic solution of silicon tetrachloride ) 2,3-dibromo-1-propanol, the dropwise addition process controls the temperature below 8°C, after the drop is completed, the temperature is raised to 35°C for 1h, and the temperature is kept for 1h, after the hydrogen chloride is released, add 33.08g (0.1mol) Tribromophenol, heat up to 70°C, keep warm for 3 hours, after the hydrogen chloride is released, cool down to below 40°C, then add 43.58g (0.2mol) 2,3-dibromo-1-propanol dropwise, and control the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com