Multi-state double-wire electrical arc welding device and welding method

An arc welding method and welding method technology, which are applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as reducing welding heat input, reduce welding heat input, improve welding wire deposition rate, and increase welding wire deposition. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

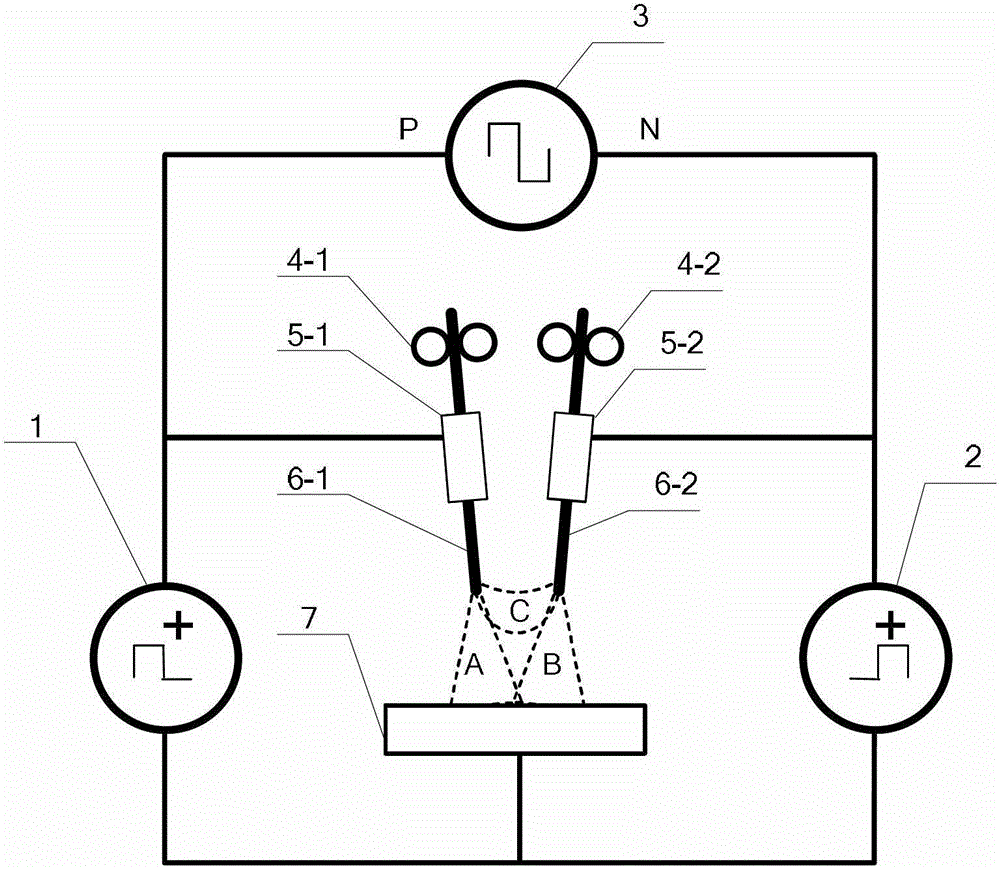

[0031] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the multi-state twin-wire arc welding device described in this embodiment includes a first DC pulse power supply 1, a second DC pulse power supply 2, a variable polarity welding power supply 3, a first wire feeding mechanism 4- 1. The second wire feeding mechanism 4-2, the first contact tip 5-1, the second contact tip 5-2, the first welding wire 6-1 and the second welding wire 6-2,

[0032] The positive pole of the first DC pulse power supply 1 is connected to the P pole of the variable polarity welding power supply 3, the N pole of the variable polarity welding power supply 3 is connected to the positive pole of the second DC pulse power supply 2, and the negative pole of the second DC pulse power supply 2 is connected to The negative pole of the first DC pulse power supply 1 is connected to the center of a side of the workpiece 7 to be welded, and the side of the workpiece 7...

specific Embodiment approach 2

[0036]Specific Embodiment 2: This embodiment will further explain Embodiment 1. The first DC pulse power supply 1 and the second DC pulse power supply 2 in this embodiment are both DC pulse power supplies. The first DC pulse power supply 1 and the second DC pulse power supply Both the DC pulse power supply 2 and the variable polarity welding power supply 3 have constant current output characteristics, constant voltage output characteristics and high resistance output characteristics.

specific Embodiment approach 3

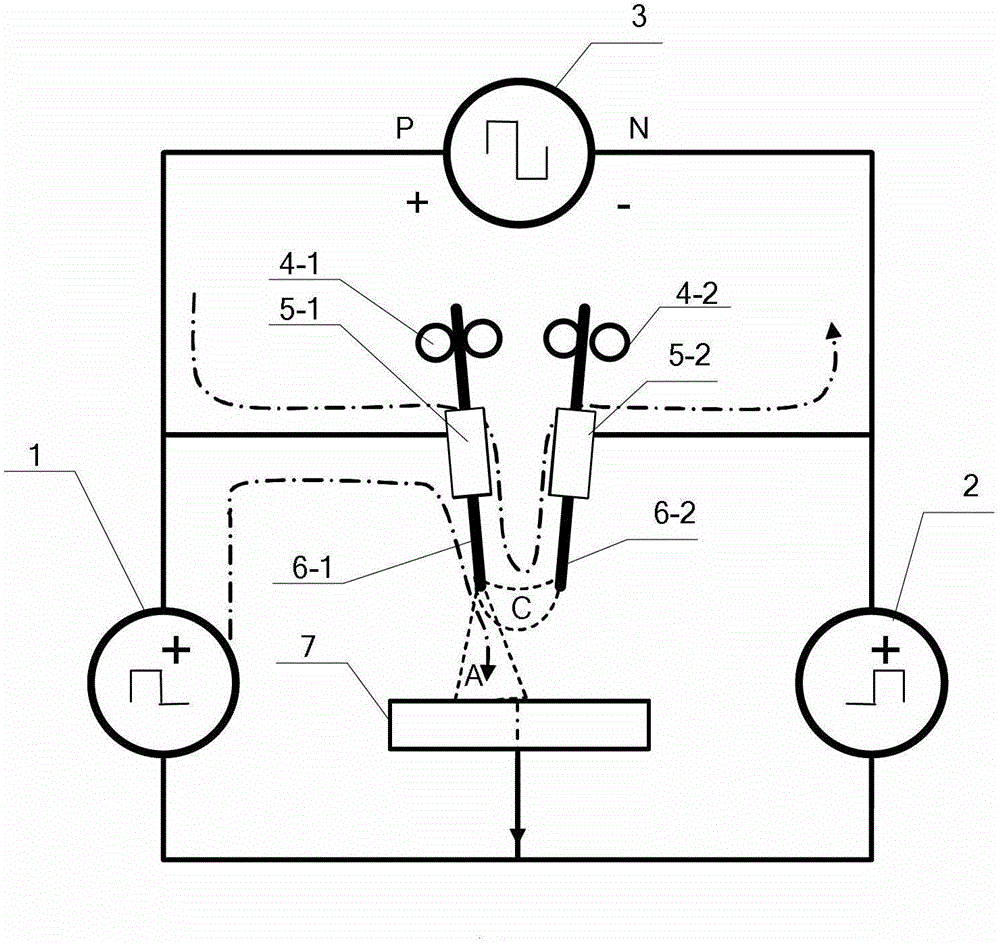

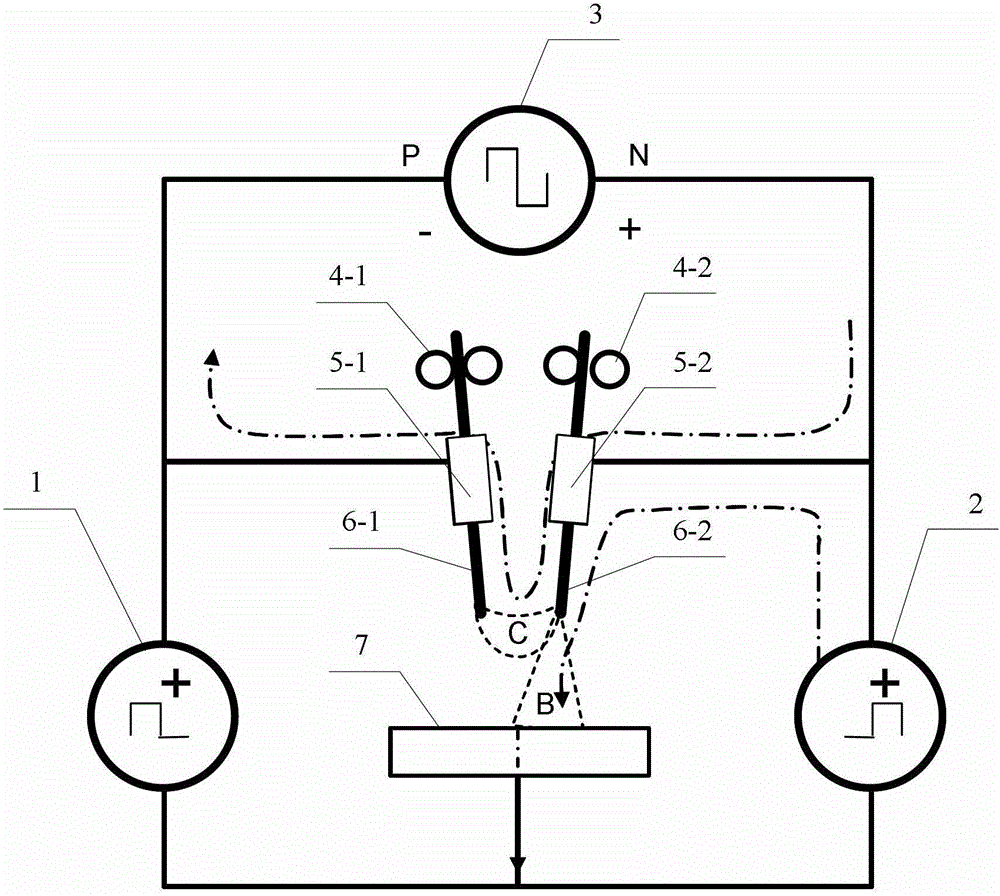

[0037] Specific implementation mode three: the following combination Figure 1 to Figure 4 Describe this embodiment, this embodiment is the multi-state twin-wire arc welding method based on the multi-state twin-wire arc welding device described in one of the above embodiments, which includes the following two stages:

[0038] The first stage:

[0039] Make the first DC pulse power supply 1 a constant voltage output, the second DC pulse power supply 2 a high-impedance output, the P pole of the variable polarity welding power supply 3 is positive, and the N pole is negative. At this time, the first DC pulse power supply 1 A left main arc A is formed between the first welding wire 6-1 and the workpiece 7 to be welded; the variable polarity welding power supply 3 forms an indirect arc C between the ends of the first welding wire 6-1 and the second welding wire 6-2; Then the current flowing through the first welding wire 6-1 is the sum of the current I1 produced by the first DC pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com