Array substrate, display device and fabrication method of array substrate

An array substrate and substrate technology, which is applied in the field of flat panel display manufacturing, can solve problems such as data line breakage, and achieve the effects of reducing breakage, strong corrosion resistance, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

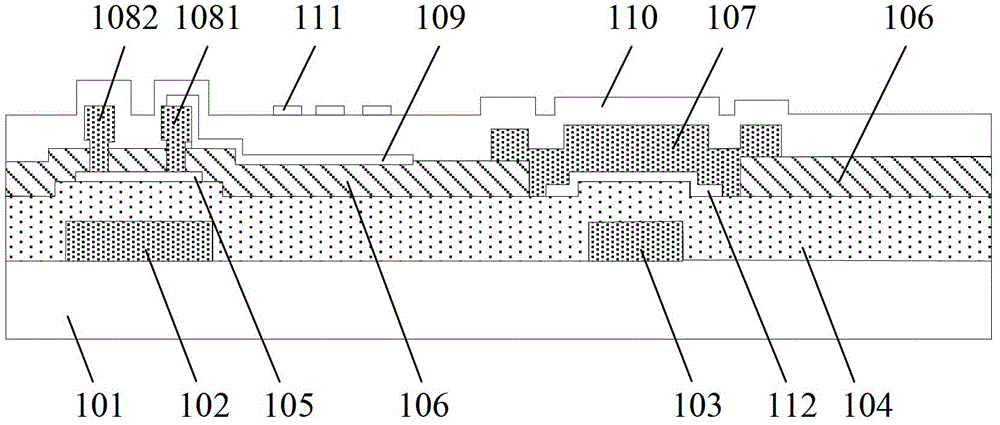

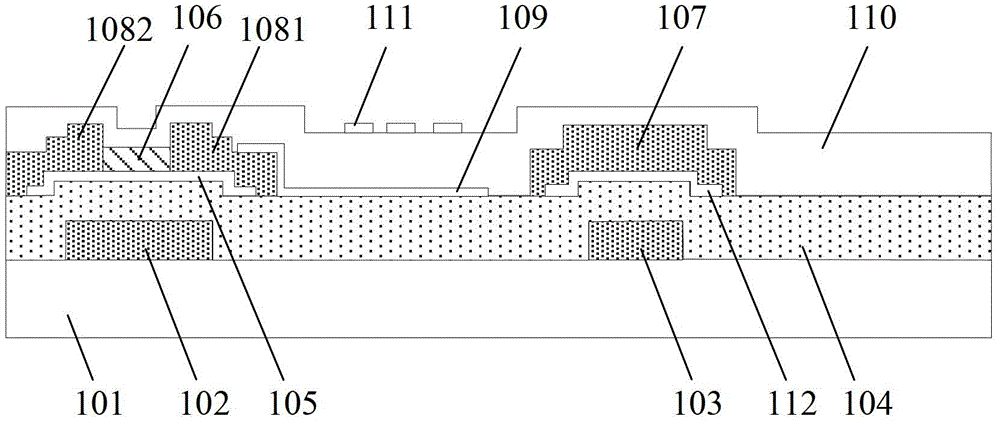

[0035] The implementation process of the embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the same or similar reference numerals represent the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

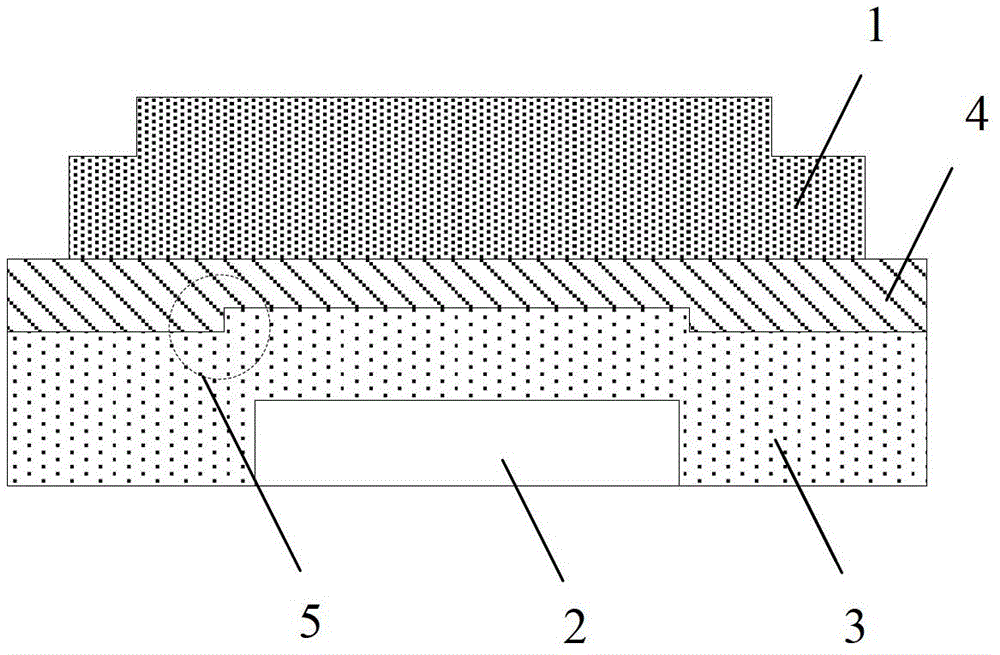

[0036] see figure 2 , the embodiment of the present invention provides an array substrate, including a substrate 101, a thin film field effect transistor TFT and a data line 107 are formed on the substrate, the TFT includes a gate electrode 102, an active layer 105, a source electrode 1082 and a drain electrode 1081; A gate insulating layer 104 is formed between the electrode 102 and the active layer 105; the array substrate includes a protective layer 112, and the protective layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com