Blue fluorescence single crystal zinc telluride nanorod as well as preparation method and application thereof

A technology of blue fluorescence and nanorods, applied in chemical instruments and methods, nanotechnology, single crystal growth, etc., can solve the problems that limit the wide application of zinc telluride nanorods, difficulty in large-scale preparation, high reaction temperature, etc., to achieve The method is simple and easy, the reaction conditions are mild, and the fluorescence yield is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of reaction precursor

[0033] Weigh 0.5 mmol zinc sulfate and dissolve it in 50 mL n-hexane, add 0.5 mmol undecylenic acid and 25 mL deionized water at the same time, stir well to form a water-oil reaction system, and bubbling nitrogen for 1 hour to obtain a reaction precursor solution.

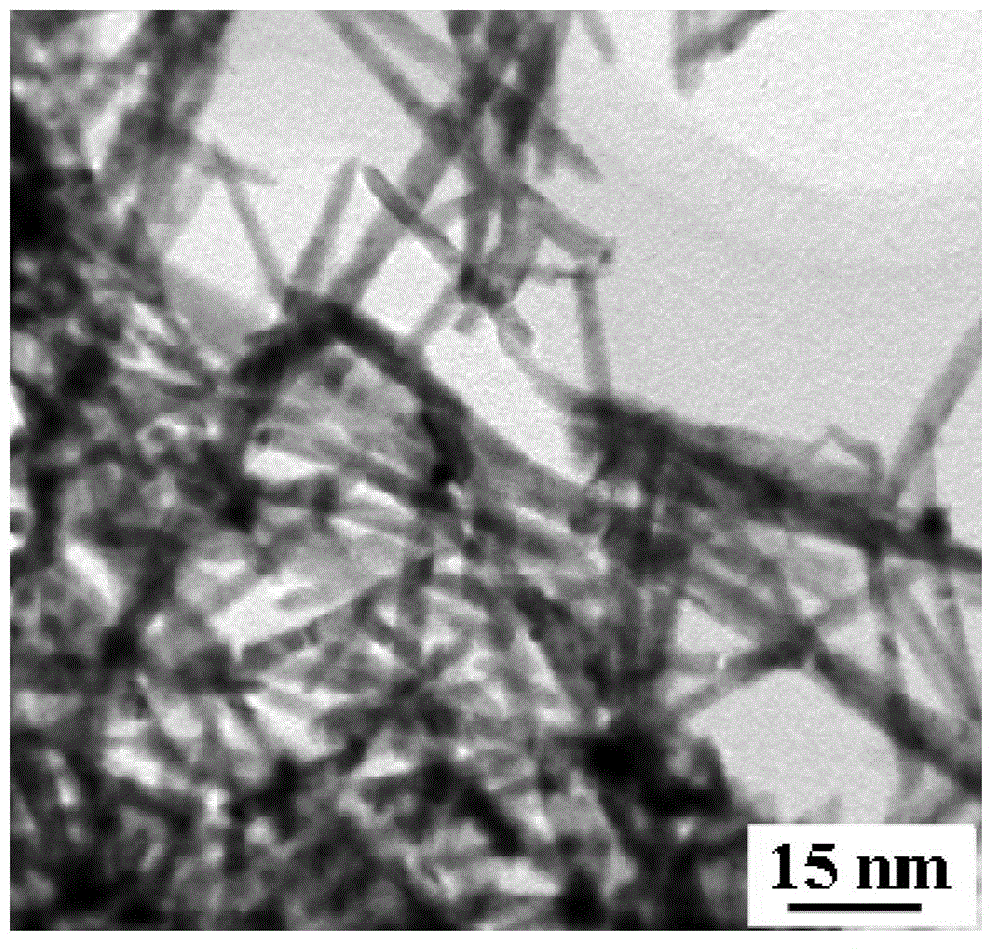

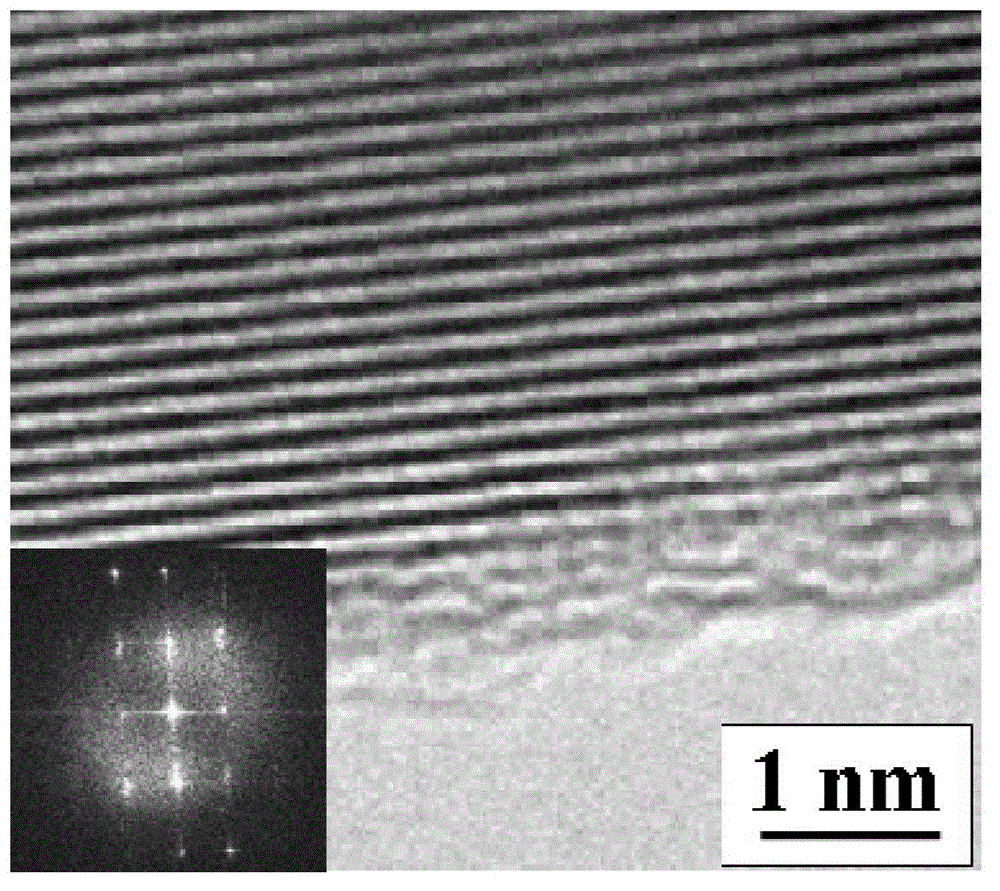

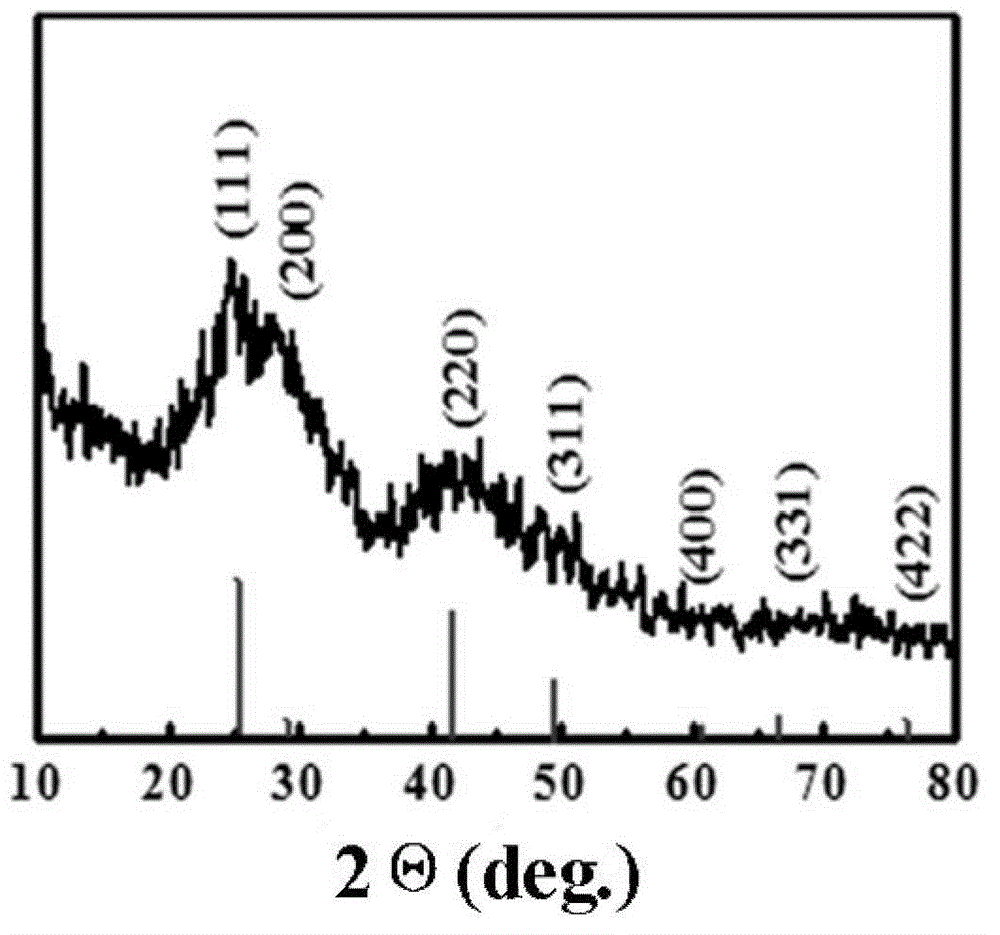

[0034] 2. Preparation of zinc telluride single crystal nanorods

[0035] Measure 5 mL of sodium tellurium hydride with a molar concentration of 0.1M, and inject it dropwise into the reaction precursor solution under the protection of a nitrogen atmosphere, continue to stir for 2 hours, the stirring speed is 100 rpm, the water bath is heated to 25° C., and the reaction is stopped after 0.5 hours. Take the upper n-hexane phase solution and precipitate it with a large amount of ethanol, and centrifuge it at 3000 rpm for 5 min. After repeated washing and vacuum drying, the zinc telluride single crystal nanorod powder with blue fluorescence is obtained. The diameter of the nanorod ...

Embodiment 2

[0039] 1. Preparation of reaction precursor

[0040] Weigh 0.5 mmol zinc acetate and dissolve it in 20 mL chloroform, add 5 mmol oleic acid and 10 mL deionized water at the same time, stir well to form a water-oil reaction system, and bubbling nitrogen for 1 hour to obtain a reaction precursor solution.

[0041] 2. Preparation of zinc telluride single crystal nanorods

[0042] Measure 10 mL of sodium tellurium hydride with a molar concentration of 0.5M and inject it dropwise into the reaction precursor solution protected by a nitrogen atmosphere. After stirring for 2 hours, the stirring speed is 200 rpm, the water bath is heated to 50° C., and the reaction is stopped after 5 hours. The lower layer of chloroform phase solution was precipitated with a large amount of ethanol, and centrifuged at 5000 rpm for 10 min, washed repeatedly and vacuum dried to obtain zinc telluride single crystal nanorod powder with blue fluorescence. The diameter of the nanorod is 1nm, the length is 10nm, th...

Embodiment 3

[0046] 1. Preparation of reaction precursor

[0047] Weigh 10mmol zinc chloride and dissolve it in 20mL n-hexane, add 20mmol stearic acid and 20mL deionized water at the same time, fully stir to form a water-oil reaction system, and bubbling nitrogen for 1h to obtain a reaction precursor solution.

[0048] 2. Preparation of zinc telluride single crystal nanorods

[0049] Measure 20 mL of sodium tellurium hydride with a molar concentration of 0.5M and inject it dropwise into the reaction precursor solution protected by a nitrogen atmosphere. After stirring for 2 hours, the stirring speed is 300 rpm, the water bath is heated to 70° C., and the reaction is stopped after 7 hours. The upper layer of the n-hexane phase solution was precipitated with a large amount of ethanol, and centrifuged at 6000 rpm for 20 minutes, washed repeatedly and vacuum dried to obtain zinc telluride single crystal nanorod powder with blue fluorescence. The diameter of the nanorod is 3nm, the length is 20nm, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com