Plate strip temperature pickling process

A pickling and stripping technology, which is applied in the field of stainless steel pickling, can solve the problems of prolonging the chemical reaction time, lowering the temperature of the stainless steel plate, and reducing the temperature of the stainless steel plate, so as to shorten the pickling time, improve the production efficiency and reduce the production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

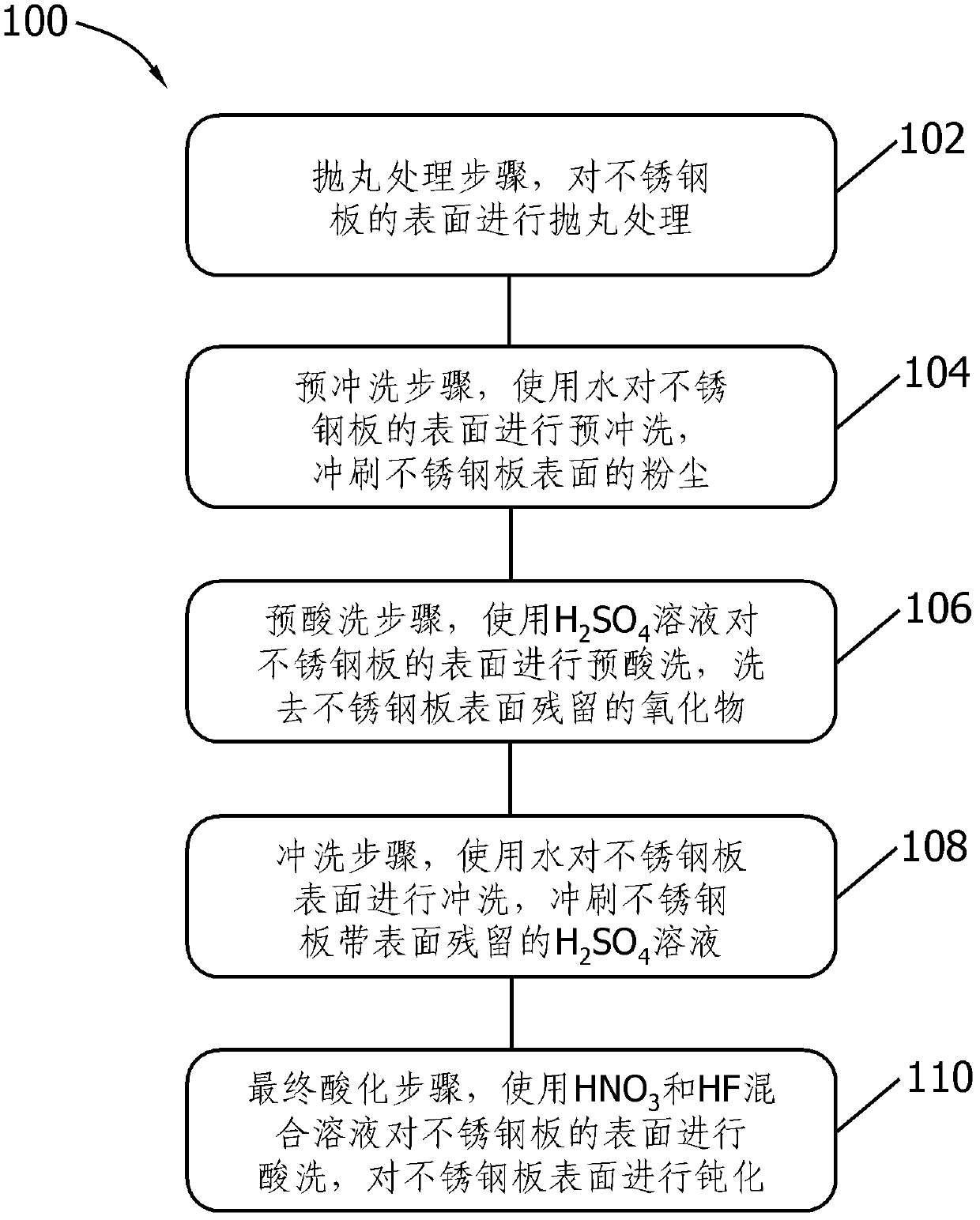

Method used

Image

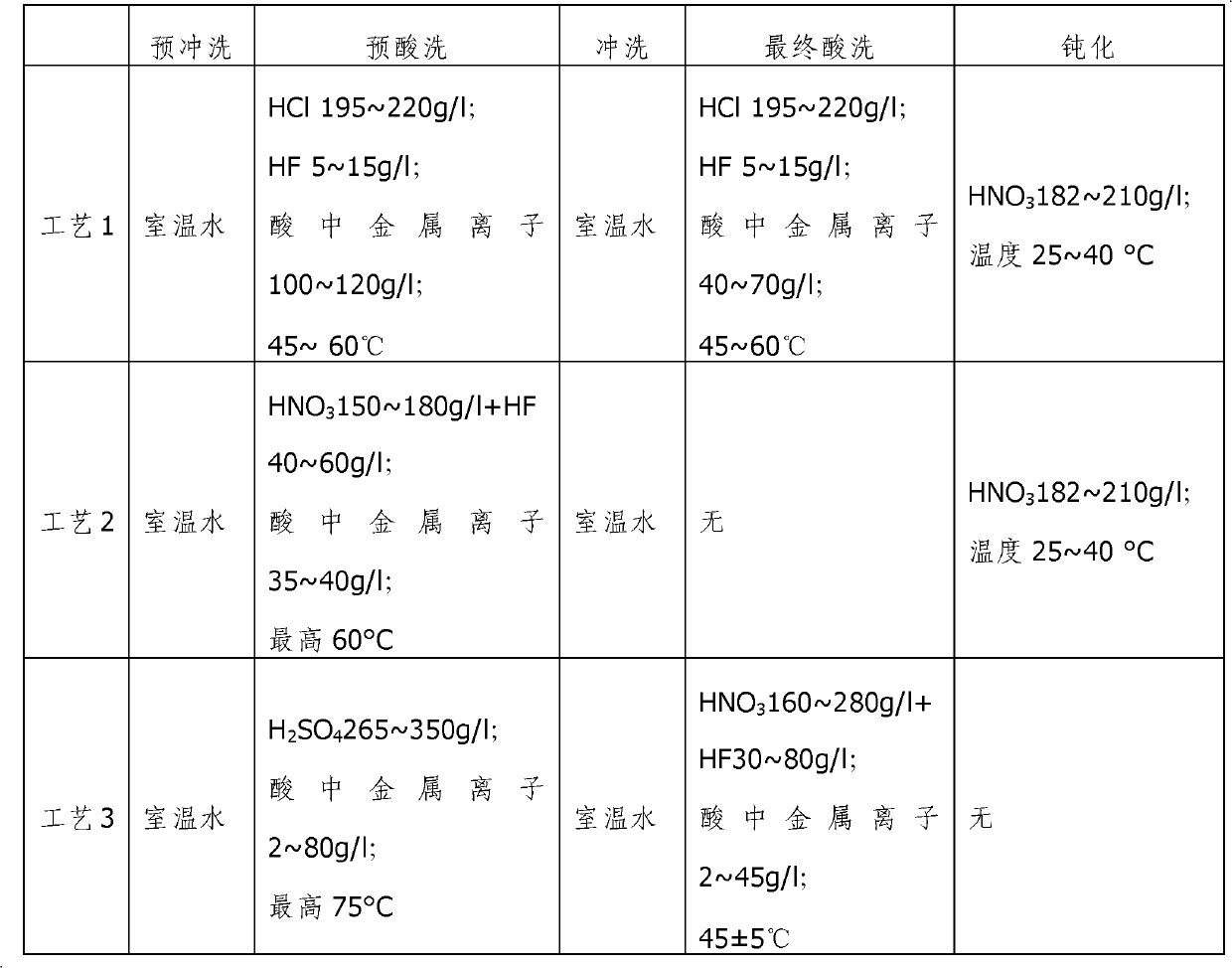

Examples

example 1

[0044] Example 1: Pickling of 304 hot-rolled stainless steel plate

[0045] The thickness of the steel plate is 10mm, the width is 2000mm, and the length is 8000mm.

[0046] The surface of the hot-rolled stainless steel plate is shot blasted, and then the hot-rolled stainless steel plate is sent to the pre-washing section (cover) through the roller table, and the water temperature is 55~65℃: the hot-rolled stainless steel plate enters the pre-pickling section (cover) after being rinsed. Pre-pickling, the composition of the pre-pickling solution: H 2 SO 4 , 300g / l; Metal ion content in acid: 35g / l, the running speed of the hot-rolled stainless steel plate is maintained at 5m / min, the temperature of the pickling solution is 60℃; after the pre-pickling section (cover), the hot-rolled stainless steel plate Enter the washing section (hood), the water temperature is 40-50℃; after the hot-rolled stainless steel plate exits the washing section (hood), it enters the final pickling section (...

example 2

[0047] Example 2: Pickling of 316L hot rolled stainless steel plate

[0048] The thickness of the steel plate is 20mm, the width is 2200mm, and the length is 6000mm.

[0049] The surface of the hot-rolled stainless steel plate is shot blasted, and then the hot-rolled stainless steel plate is sent to the pre-washing section (cover) through the roller table, and the water temperature is 58~68℃: the hot-rolled stainless steel plate enters the pre-pickling section (cover) after being rinsed. Pre-pickling, the composition of the pre-pickling solution: H 2 SO 4 , 280g / l; metal ion content in acid: 20g / l, the running speed of the hot-rolled stainless steel plate is maintained at 4m / min, the temperature of the pickling solution is 58℃; after the pre-pickling section (cover), the hot-rolled stainless steel plate Enter the washing section (hood), the water temperature is 45~55℃; after the hot-rolled stainless steel plate exits the washing section (hood), it enters the final pickling section ...

example 3

[0050] Example 3: Pickling of S31803 hot-rolled stainless steel plate

[0051] The thickness of the steel plate is 30mm, the width is 1800mm, and the length is 5800mm.

[0052] The surface of the hot-rolled stainless steel plate is shot blasted, and then the hot-rolled stainless steel plate is sent to the pre-washing section (cover) through the roller table, and the water temperature is 65~75: the hot-rolled stainless steel plate enters the pre-pickling section (cover) for pre-washing after being washed Pickling, pre-pickling solution composition: H 2 SO 4 , 320g / l; metal ion content in acid: 19g / l, the running speed of the hot-rolled stainless steel plate is maintained at 0.6m / min, the temperature of the pickling solution is 66℃; after the pre-pickling section (hood), the stainless steel is hot-rolled The plate enters the washing section (hood), and the water temperature is 55-65℃; after the hot-rolled stainless steel plate exits the washing section (hood), it enters the final pic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com