Passivation solution capable of inhibiting formation of hexavalent chromium in trivalent chromium passivation layer as well as preparation method and application of passivation solution

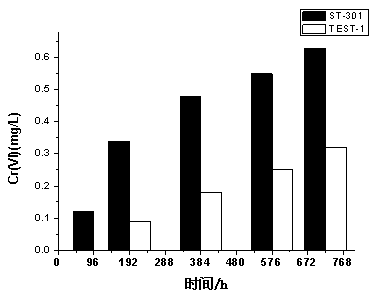

A technology of hexavalent chromium in the passivation layer, applied in the direction of metal material coating process, etc., can solve problems such as the influence of the export market, and achieve stable formation process of passivation layer, uniform surface of passivation layer, and ease of oxidation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054]A passivation solution for inhibiting the formation of hexavalent chromium in the trivalent chromium passivation layer, calculated per liter, the composition and content of its raw materials are as follows:

[0057] Cobalt Sulfate Heptahydrate 4.0g

[0058] Sodium hypophosphite 2.5g

[0059] Citric acid 0.4g

[0060] Ammonium bifluoride 0.15g

[0061] Sodium D-gluconate 0.8g

[0062] Acetic acid 0.4g

[0063] The balance is deionized water.

[0064] Above-mentioned a kind of preparation method that suppresses the passivation solution that hexavalent chromium forms in the trivalent chromium passivation layer, concrete steps are as follows:

[0065] Pour 15g of chromium sulfate into a 1500mL beaker, add 200mL of deionized water, control the stirring speed to 12r / min, put the beaker in a constant temperature water bath at 30°C to completely dissolve the chromium sulfate;

[0066] Then add 1.5g of sodium nitr...

Embodiment 2

[0080] A passivation solution for inhibiting the formation of hexavalent chromium in the trivalent chromium passivation layer, calculated per liter, the composition and content of its raw materials are as follows:

[0081] Chromium sulfate 25g

[0082] Sodium nitrate 3.0g

[0083] Cobalt Sulfate Heptahydrate 9.0g

[0084] Sodium hypophosphite 5.0g

[0085] Citric acid 1.0g

[0086] Ammonium bifluoride 0.25g

[0087] Sodium D-gluconate 1.25g

[0088] Acetic acid 1.0g

[0089] The balance is deionized water.

[0090] Above-mentioned a kind of preparation method that suppresses the passivation solution that hexavalent chromium forms in the trivalent chromium passivation layer, concrete steps are as follows:

[0091] Pour 25g of chromium sulfate into a 1500mL beaker, add 200mL of deionized water, control the stirring speed to 12r / min, put the beaker into a constant temperature water bath at 30°C to completely dissolve the chromium sulfate;

[0092] Then add 3.0g of sodium ...

Embodiment 3

[0096] A passivation solution for inhibiting the formation of hexavalent chromium in the trivalent chromium passivation layer, calculated per liter, the composition and content of its raw materials are as follows:

[0097] Chromium sulfate 20g

[0098] Sodium nitrate 2.0g

[0099] Cobalt Sulfate Heptahydrate 6.0g

[0100] Sodium hypophosphite 3.0g

[0101] Citric acid 0.7g

[0102] Ammonium bifluoride 0.2g

[0103] Sodium D-gluconate 1.0g

[0104] Acetic acid 0.8g

[0105] The balance is deionized water.

[0106] Above-mentioned a kind of preparation method that suppresses the passivation solution that hexavalent chromium forms in the trivalent chromium passivation layer, concrete steps are as follows:

[0107] Pour 20g of chromium sulfate into a 1500mL beaker, add 200mL of deionized water, control the stirring speed to 12r / min, put the beaker into a constant temperature water bath at 30°C to completely dissolve the chromium sulfate;

[0108] Then add 2.0g of sodium ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com