Method for healing copper thin film fatigue damages by plurality of times of laser impact

A technology of fatigue damage and laser shock, applied in the fields of mechanical manufacturing and laser processing applications, to achieve the effect of increasing cumulative fatigue life, simple construction, and improved fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

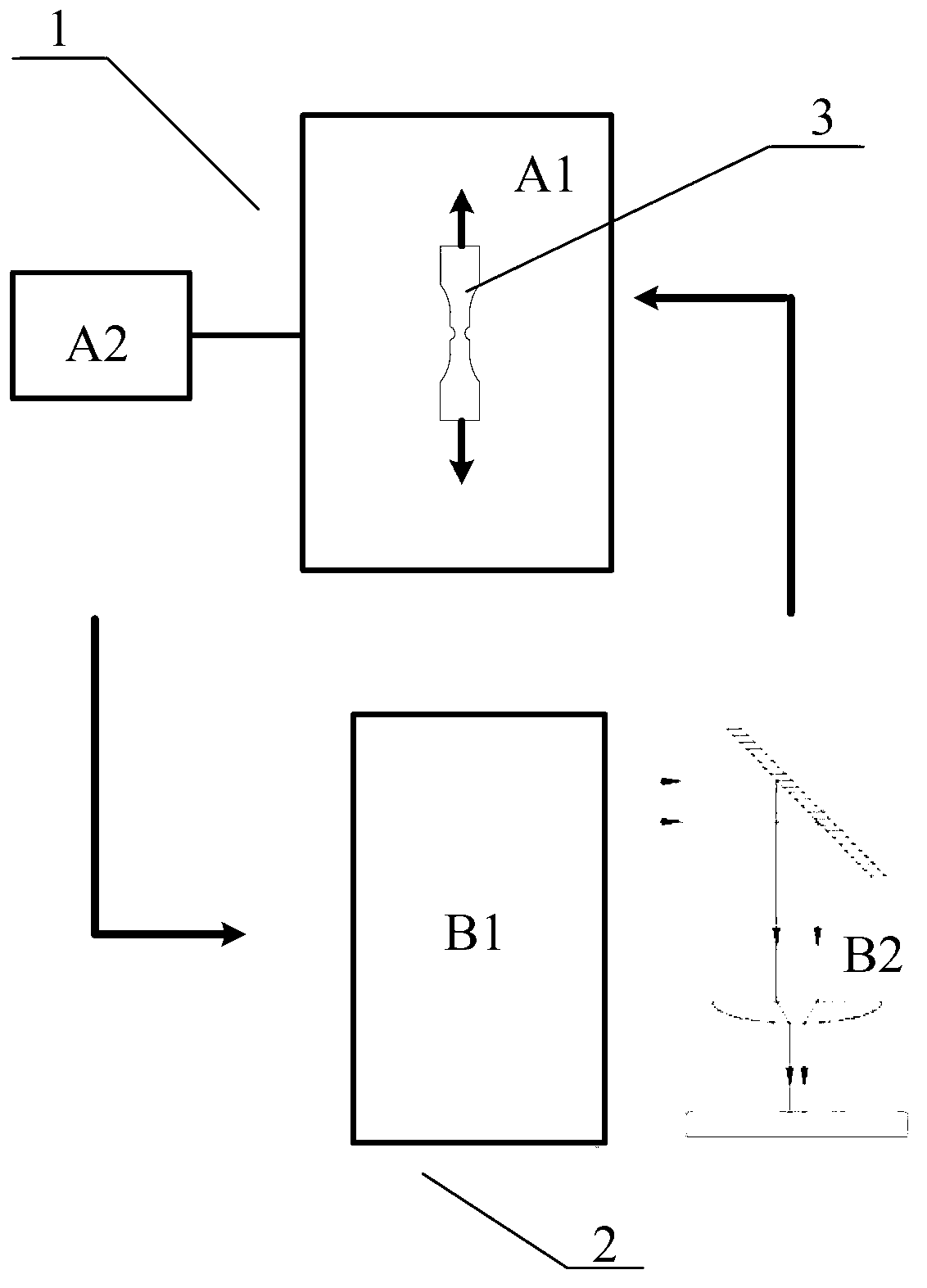

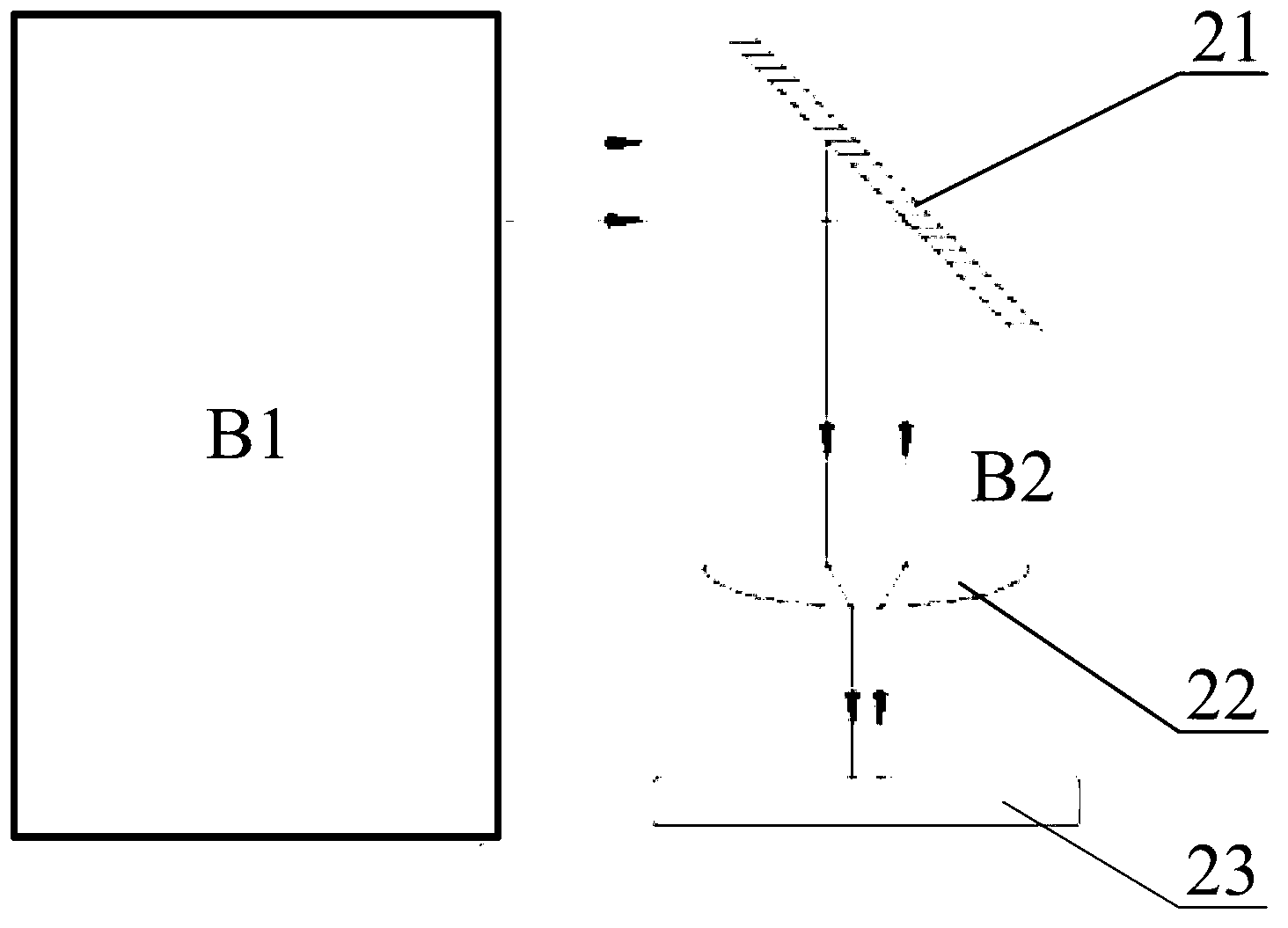

[0029] Below in conjunction with accompanying drawing, the method of the present invention is further described, please refer to Figure 1 to Figure 6 , a polycrystalline copper thin film material laser shock healing method, the steps are:

[0030] Step 1): Provide a prefabricated fatigue damage device 1 and a laser shock healing device 2 for metal specimens, the prefabricated fatigue damage device 1 includes a micro-fatigue testing machine A1 and a video microscope A2, and the laser shock healing device 2 includes a pulsed laser B1, Optical path adjusting device B2 and culture dish 23, described optical path adjusting device B2 comprises mirror adjusting device 21, lens adjusting device 22; Reflecting mirror adjusting device 21 is made up of reflecting mirror support, reflecting mirror and slider mechanism, lens adjusting device 22 is made up of lens holder, convex lens and slide block;

[0031] Step 2): Prefabricate fatigue damage to the material and observe it from time to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com