Low-luster aqueous polyurethane dispersion for leather, and preparation method and application thereof

A water-based polyurethane and dispersion technology, applied in polyurea/polyurethane coatings, textiles, papermaking, coatings, etc., can solve problems such as difficult artificial leather and synthetic leather applications, expensive solutions, solvent residues, etc., to achieve catalyst safety and environmental protection, Increased micro-roughness and improved rub resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

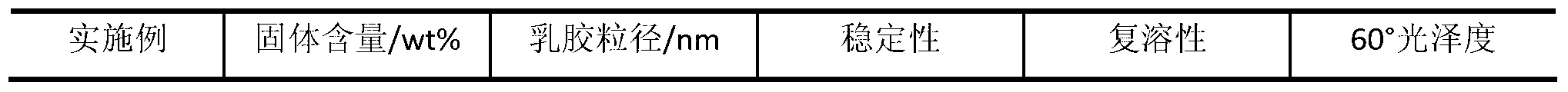

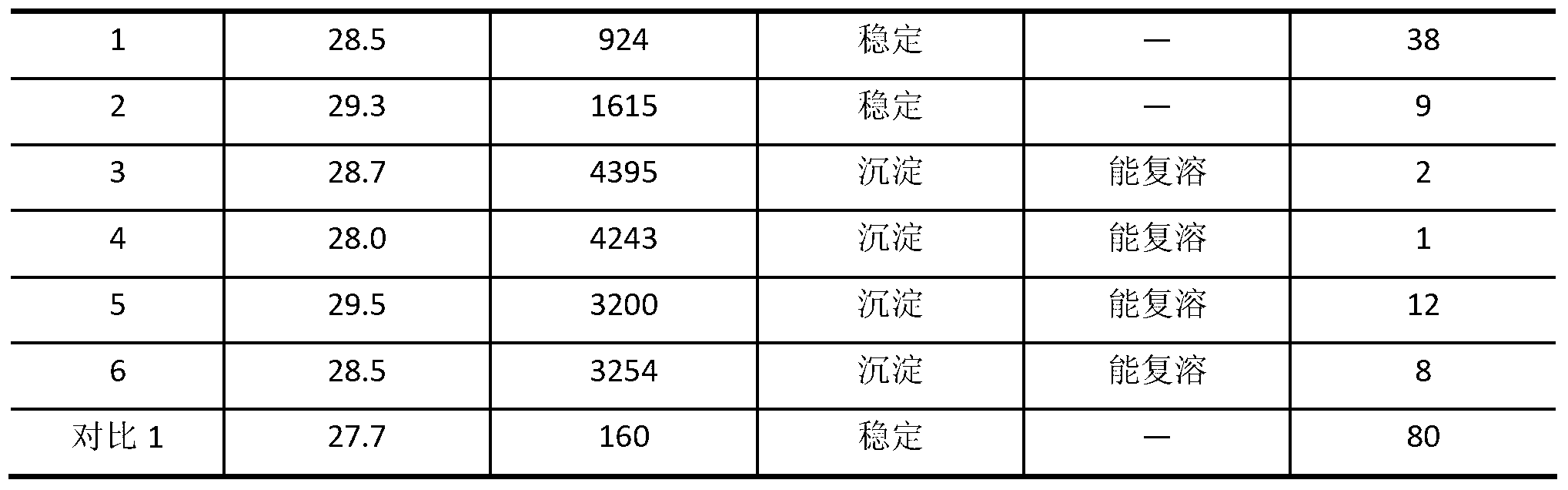

Examples

Embodiment 1

[0038](1) After dehydrating 110g polytetrahydrofuran diol (PTMG‐1000, 1000g / mol, Mitsubishi Chemical Corporation), 4.2g dimethylolpropionic acid (DMPA, Perstorp, Sweden), cool to 60 ℃, add 4 drops of organic bismuth catalyst (Bicat8108, American leading chemical), and mix well. Under nitrogen protection, continue to drop into 54g isophorone diisocyanate (IPDI, Bayer Materials Science) to carry out prepolymerization reaction, every 15 minutes extract sample and judge reaction end point with n-butylamine titration, when -NCO value reaches 4.3 (theoretical value 5.08) when the prepolymer is cooled to about 60 ° C;

[0039] (2) Add 4.3g of neutralizing agent tripropylamine to the product of step (1) to neutralize and form salt for 30 minutes, and further cool to 30°C;

[0040] (3) Put the product of step (2) into a solution containing 3g of sodium sulfamate chain extender (VESTAMIN A95, Evonik Degussa) and 300g of deionized water, continue to emulsify and extend the chain for 30 ...

Embodiment 2

[0044] (1) 110g polytetrahydrofuran diol (PTMG‐1000, 1000g / mol, Japan Mitsubishi Chemical Co., Ltd.), 4.4g dimethylol propionic acid (DMPA, Swedish Perstorp Company) were dehydrated and cooled to 60 ℃, add 4 drops of organic bismuth catalyst (Bicat8108, American leading chemical), and mix well. Under the protection of nitrogen, continue to drop into 62g isophorone diisocyanate (IPDI, Bayer Materials Science) to carry out prepolymerization reaction, every 15 minutes extract the sample and use n-butylamine titration method to judge the reaction end point, when -NCO value reaches 5.7 (theoretical value When it is 6.49), the prepolymer is cooled to about 60°C;

[0045] (2) Add 3.2g neutralizing agent triethylamine to the product of step (1) to neutralize and form salt for 20 minutes, and further cool to 30°C;

[0046] (3) Put the product of step (2) into a solution containing 3g of sodium sulfamate chain extender (X506, BASF, Germany) and 300g (or 600g) of deionized water, contin...

Embodiment 3

[0050] (1) 220g polytetrahydrofuran diol (PTMG‐2000, 2000g / mol, Japan Mitsubishi Chemical Co., Ltd.), 6.2g dimethylol propionic acid (DMPA, Swedish Perstorp Company) were dehydrated and cooled to 70 ℃, add 6 drops of organic bismuth catalyst (Bicat8108, American leading chemical), and mix well. Under the protection of nitrogen, continue to drop into 64g isophorone diisocyanate (IPDI, Bayer Materials Science) to carry out prepolymerization reaction, every 15 minutes extract the sample and use n-butylamine titration method to judge the reaction end point, when -NCO value reaches 3.4 (theoretical value When it is 3.82), the prepolymer is cooled to about 60°C;

[0051] (2) Add 4.5 g of neutralizing agent triethylamine to the product of step (1) to neutralize and form salt for 40 minutes, and further cool to 45°C;

[0052] (3) Put the product of step (2) into a solution containing 4g of sodium sulfamate chain extender (VESTAMIN A95, Evonik Degussa) and 400g of deionized water, con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com