Fire retardant di(tribromophenoxy)dihalidepropoxysilane compound and its preparation method

A technology of dihalopropoxysilane and tribromophenoxy, which is applied in the field of flame retardant dihalopropoxysilane compounds and their preparation, can solve the problems of high price and application restrictions of silicon-based flame retardants, Achieve the effect of good compatibility, high flame retardant efficiency, and reduce the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

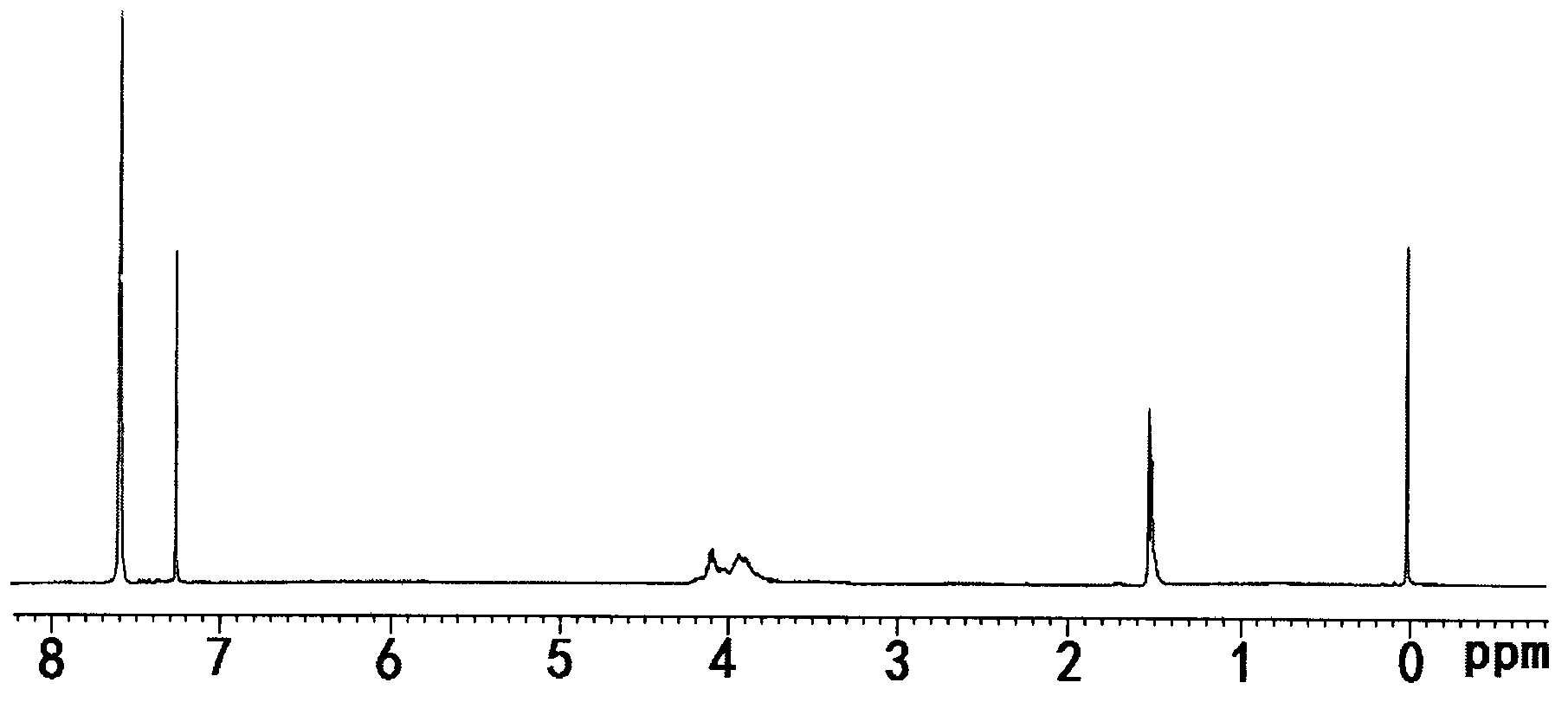

Image

Examples

Embodiment 1

[0032] Example 1 In the 500ml four-necked flask equipped with agitator, thermometer, dropping funnel and high-efficiency reflux condenser and a hydrogen chloride absorbing device connected in series with a drying tube at the top of the condenser, replace the air in the bottle with nitrogen , add 150ml of carbon tetrachloride and 16.99g (0.1mol) of silicon tetrachloride, under stirring, cool with ice-water bath, make the reaction system temperature drop to 0 ℃, dropwise add 9.45g in the organic solution of silicon tetrachloride (0.1mol) 2-chloro-1-propanol, the dropwise addition process controls the temperature below 5°C, after the drop is completed, the temperature is raised to 30°C for 1h, and the temperature is kept for 1h. After the hydrogen chloride is released, add 66.16g (0.2mol) Tribromophenol, heat up to 80°C, heat preservation reaction for 5h, after the hydrogen chloride is released, cool down to below 30°C, then add 9.45g (0.1mol) 2-chloro-1-propanol dropwise, and con...

Embodiment 2

[0033] Example 2 In a 500ml four-necked flask equipped with a stirrer, a thermometer, a dropping funnel and a high-efficiency reflux condenser and a hydrogen chloride absorbing device connected in series with a drying tube at the top of the condenser, replace the air in the bottle with nitrogen , add 150ml acetonitrile and 16.99g (0.1mol) silicon tetrachloride, under stirring, cool with ice-water bath, make the temperature of reaction system drop to 0 ℃, dropwise add 9.45g (0.1mol) in the organic solution of silicon tetrachloride ) 1-chloro-2-propanol, the dropping process controls the temperature below 5°C, after the drop is completed, the temperature is raised to 30°C for 1h, and the heat preservation reaction is carried out for 1h, after the hydrogen chloride is released, add 66.16g (0.2mol) of tribromophenol , heat up to 60°C, heat preservation reaction for 6h, after the hydrogen chloride is released, cool down to below 30°C, then add 9.45g (0.1mol) 1-chloro-2-propanol drop...

Embodiment 3

[0034] Example 3 In a 500ml four-neck flask equipped with a stirrer, a thermometer, a dropping funnel and a high-efficiency reflux condenser and a hydrogen chloride absorbing device connected in series with a drying tube at the top of the condenser, replace the air in the bottle with nitrogen , add 150ml dioxane and 16.99g (0.1mol) silicon tetrachloride, under stirring, cool with ice-water bath, make the reaction system temperature drop to 0 ℃, dropwise add 9.45g in the organic solution of silicon tetrachloride (0.1mol) 3-chloro-1-propanol, the dropwise addition process controls the temperature below 5°C, after the drop is completed, the temperature is raised to 30°C for 1h, and the temperature is kept for 1h. After the hydrogen chloride is released, add 66.16g (0.2mol) Tribromophenol, heat up to 90°C, keep warm for 4 hours, after the hydrogen chloride is released, cool down to below 30°C, then add 9.45g (0.1mol) 3-chloro-1-propanol dropwise, and control the temperature not to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com