Hydrogen bromide gas drying method

A hydrogen bromide and gas technology, which is applied in the fields of inorganic chemical industry and hydrogen bromide gas purification, can solve the problems of high dehydration depth, difficult control, and little industrial production significance, and achieves the effect of high dehydration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

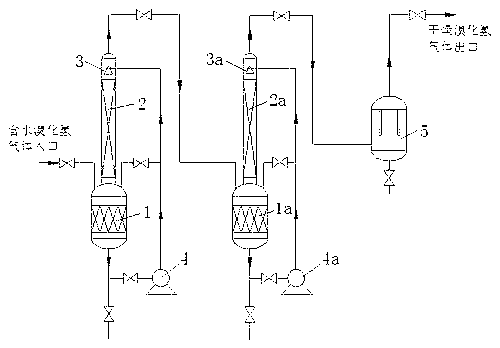

Image

Examples

Embodiment 1

[0022] Hydrogen bromide gas produced by burning bromine in hydrogen, with a flow rate of 10NM 3 / h, water content 1500-2000ppm, using two-stage series-connected packing drying tower for drying, the nominal diameter of the packing drying tower is 200mm, and the height is 1200mm. After drying, the water content in the hydrogen bromide gas is 10ppm after demisting.

Embodiment 2

[0024] Hydrogen bromide gas produced by burning bromine in hydrogen, with a flow rate of 10NM 3 / h, water content 1500-2000ppm, using two-stage series-connected packing drying tower for drying, the nominal diameter of the packing drying tower is 200mm, and the height is 1200mm. The percentage concentration is 10% phosphorous acid), and the secondary dehydrating agent uses phosphorus tribromide liquid circulation with a mass percentage concentration of 99%. After secondary dehydration and drying, the water content in the hydrogen bromide gas after demisting is 12ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com