Preparation method for non-dairy cream stabilized by solid particles

A solid particle, non-dairy cream technology, applied in the production/processing of edible oil/fat, etc., can solve the problem of affecting the development and growth of the central nervous system, difficult to meet the needs of mass consumption, and increase blood viscosity and cohesion, etc. problems, to achieve the effect of improving safety and health, good taste, and high whipping and foaming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Preparation of interface active particles:

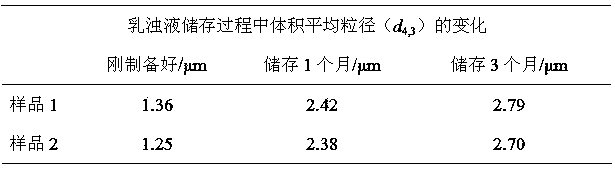

[0025] Determination of emulsifying ability: Disperse solid particles in deionized water to prepare a 1.25% dispersion, then the ratio of soybean oil to solid particle dispersion is 20:80 (v / v), and the homogeneous pressure is 300bar. Add 0.02% sodium azide to the emulsion to inhibit microbial growth. The volume average particle diameter ( d 4,3 )The change.

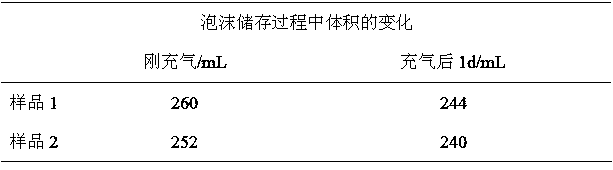

[0026] Determination of foaming and foaming ability: 100mL emulsion containing 20% soybean oil and 1% solid particles was treated with a homogenizer at 10000rpm for 1min, and then transferred to a graduated cylinder to measure the change in foam volume during storage .

[0027] Table 1 is the emulsifying ability measurement result of prepared solid particles.

[0028] Table 2 shows the foaming and foam stabilizing ability test results of the prepared solid particles.

Embodiment a

[0030] Take 100g of soybean fiber with a particle size of less than 50nm, add 1500mL of acetone, stir evenly, heat to 40°C, add 25g of ethyl cellulose, keep the temperature at 45°C, stir and reflux at 300rpm for 30min, then add 0.02M phosphate buffer solution 1500mL, continued to react for 60min, concentrated, centrifugally dehydrated, and spray-dried to obtain 114g of soybean fiber-ethylcellulose graft copolymer solid particles with interface activity.

[0031] It can be seen from Table 1 and Table 2 that the solid particles prepared in Example 1 have better emulsifying ability, foaming and foam stabilizing ability.

[0032] The oil-in-water emulsion containing 20% oil prepared by adding 1% of the solid particles was stored at room temperature for 3 months, and the emulsion remained stable. However, the emulsion without adding solid particles showed obvious phase separation after 5 minutes.

Embodiment b

[0034] Take 500g of soybean fiber with a particle size of less than 50nm, add 5000mL of acetone, stir evenly, heat to 50°C, add 500g of ethyl cellulose, keep the temperature at 55°C, stir and reflux at 600rpm for 20min, then add 0.02M phosphate buffer solution 5000mL, continued to react for 45min, concentrated, centrifugally dehydrated, and spray-dried to obtain 880g of soybean fiber-ethylcellulose graft copolymer solid particles with interface activity.

[0035] The oil-in-water emulsion containing 25% oil prepared by adding 0.8% of the solid particles was stored at room temperature for 3 months, and the emulsion remained stable. However, the emulsion without adding solid particles showed obvious phase separation after 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com