Brake device for vehicle

A technology of brake device and wheel brake cylinder, which is applied in the direction of brake transmission device, control device, braking action starting device, etc. discomfort, etc., for reliable and rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

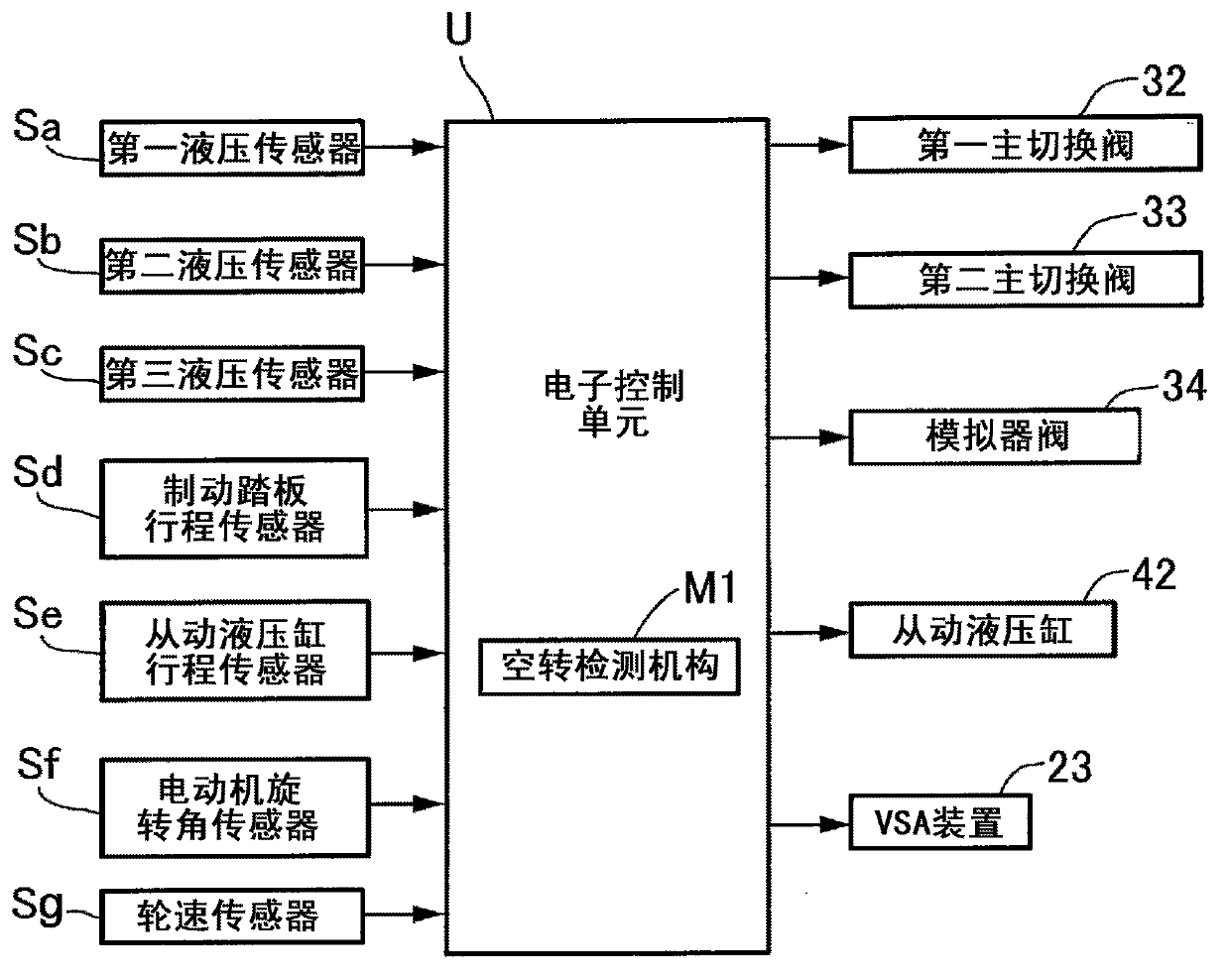

[0044] first embodiment

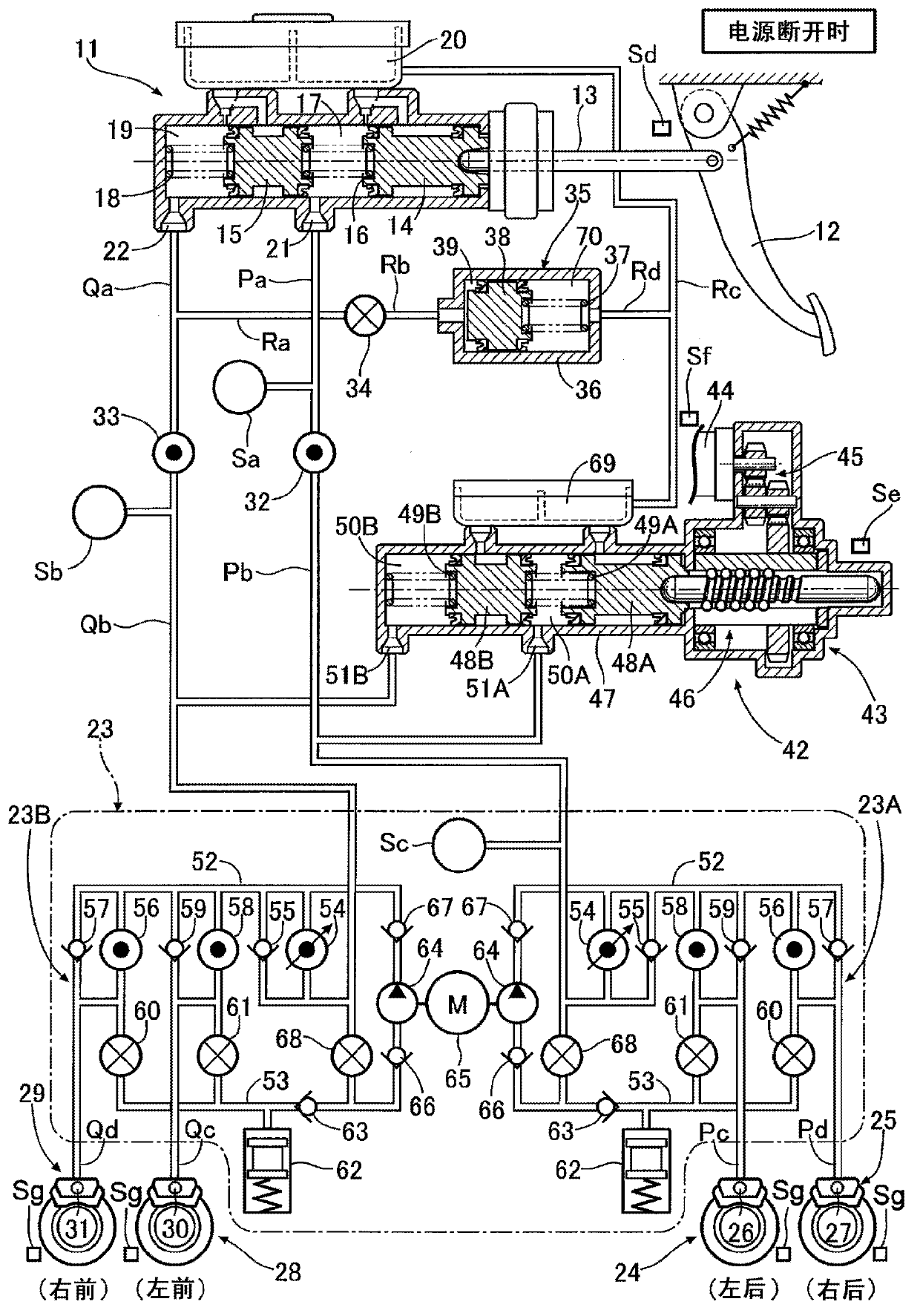

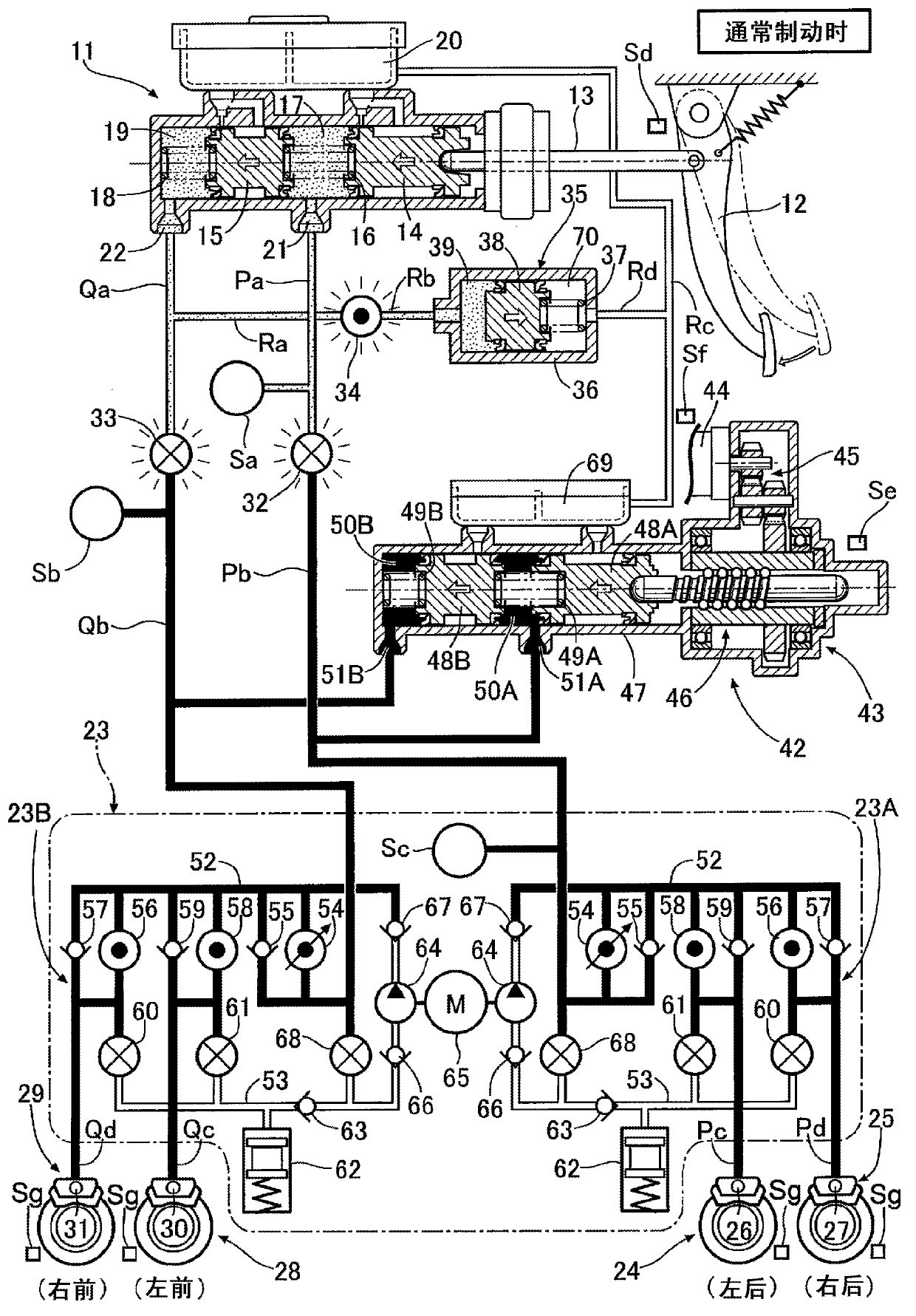

[0045] Such as figure 1 As shown, the tandem-type master hydraulic cylinder 11 has a first piston 14 connected to the brake pedal 12 operated by the driver via a push rod 13, and a second piston 15 arranged in front of the first piston 14. A first hydraulic chamber 17 containing the return spring 16 is defined between the piston 14 and the second piston 15 , and a second hydraulic chamber 19 containing the return spring 18 is defined in front of the second piston 15 . The first hydraulic chamber 17 and the second hydraulic chamber 19 , which can communicate with the reservoir 20 , respectively have a first output port 21 and a second output port 22 . The device 23 and the fluid paths Pc, Pd are connected to the wheel cylinders 26, 27 (first system) of the disc brake devices 24, 25 of the left and right rear wheels, for example, and the second output port 22 is connected via the fluid path Qa. , Qb, VSA device 23 and fluid passages Qc, Qd are connect...

no. 2 approach

[0084] The second embodiment differs from the first embodiment only in the function of the lost motion detection mechanism M1, and the other configurations are the same.

[0085] Figure 8 It is a map showing the relationship between the command voltage Vq and the torque current Iq of the motor 44 under vector control. When the motor 44 is not idling normally, as shown by the solid line, the torque current Iq increases at a fixed rate of increase with the increase of the indicated voltage Vq, and when the indicated voltage Vq further increases, the rate of increase of the torque current Iq decreases gradually . On the other hand, when the motor 44 is idling abnormally, as indicated by the dotted line, the torque current Iq increases at a fixed rate of increase that is significantly lower than that in the normal state as the indicated voltage Vq increases.

[0086] Thus, in Figure 8 In the map of , a hatched area is set in advance, and when the indicated voltage Vq and torq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com