Auto focusing mechanism of surveying instrument

A measuring machine and focus technology, which is used in measuring devices, measuring instruments, mapping and navigation, etc., can solve the problems of deterioration of AF accuracy, longer AF processing time, and adverse effects on measurement results, and achieves rapid and accurate detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

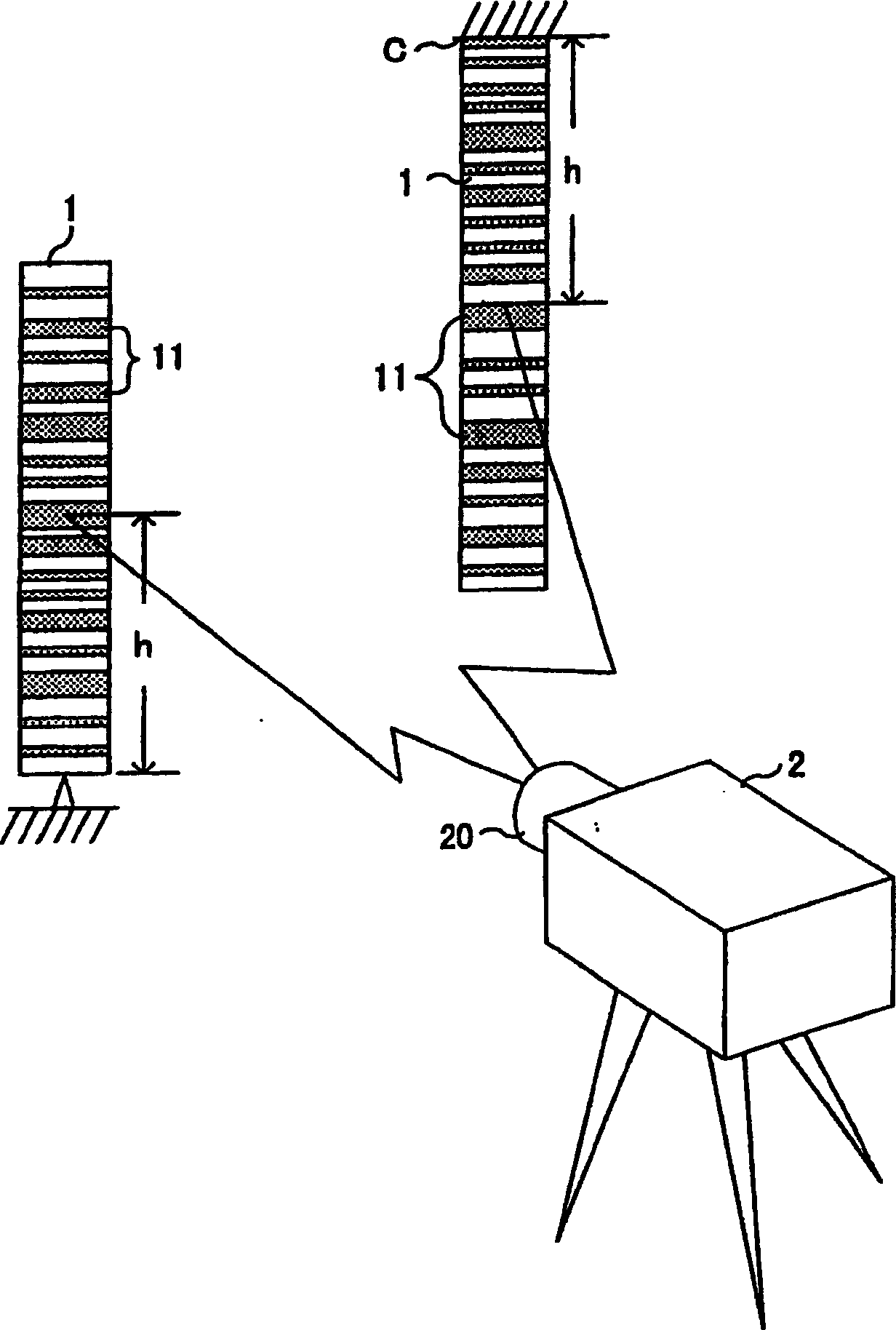

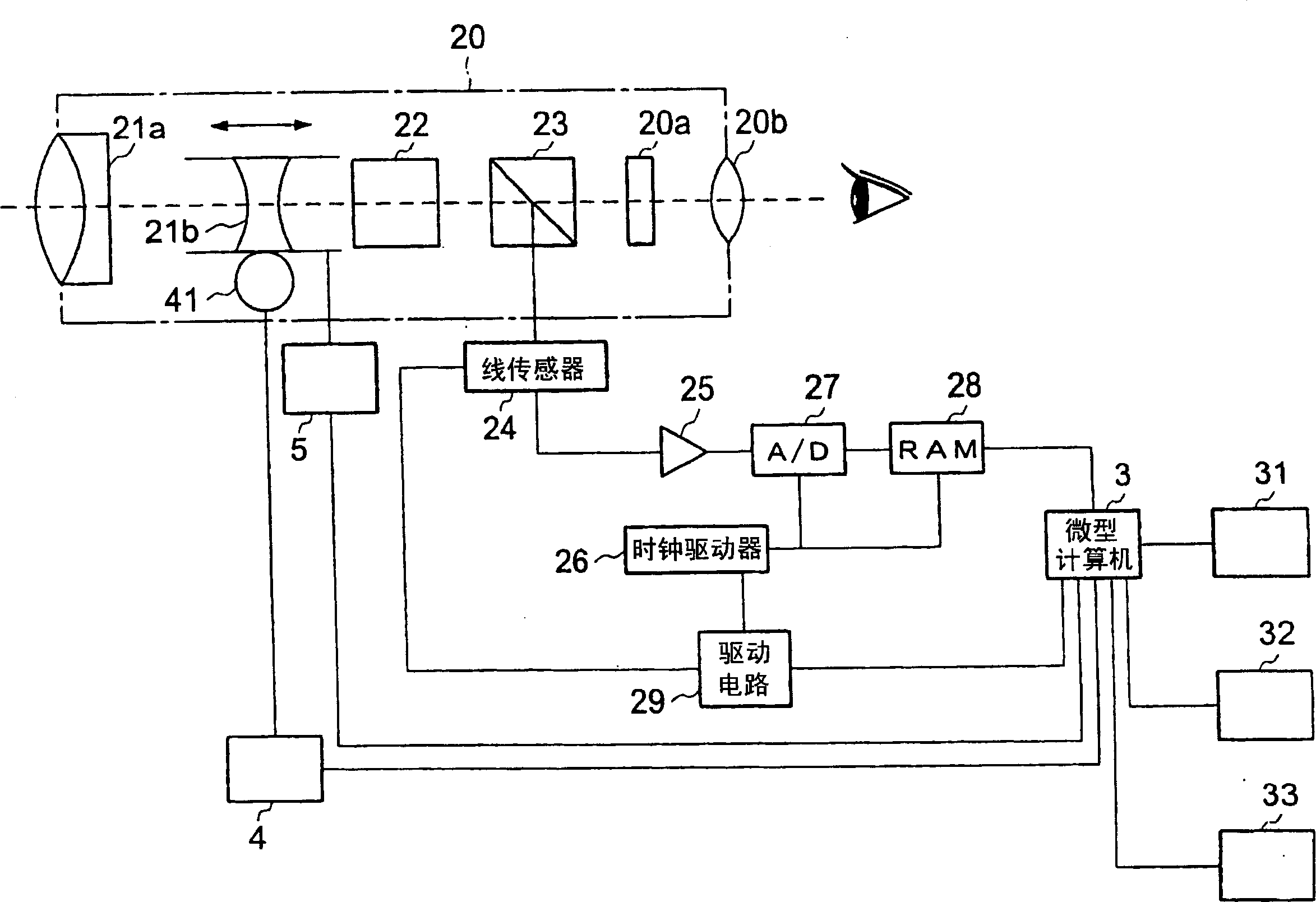

[0037] Hereinafter, embodiments of the present invention will be described based on examples. figure 1 It is a perspective view for explaining the relationship between the electronic level and the scale to which the present invention is applied, figure 2 It is a block diagram showing an automatic focus mechanism of a measuring machine according to an embodiment of the present invention.

[0038] In these figures, the electronic level 2 is configured as a measuring machine for leveling the scale 1 with a telescope 20 and measuring the height h of the leveling position. On the scale 1 , a plurality of black marks 11 are displayed at equal intervals along the vertical direction (axis direction) of the scale 1 on the surface of the white background. The width dimension in the vertical direction of each mark 11 is not completely the same size, and marks 11 of various sizes are arranged on the scale 1 in a predetermined order. That is, on the scale 1, a plurality of patterns for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com