Blended gel polymer electrolyte thin film with porous appearance and preparation method thereof

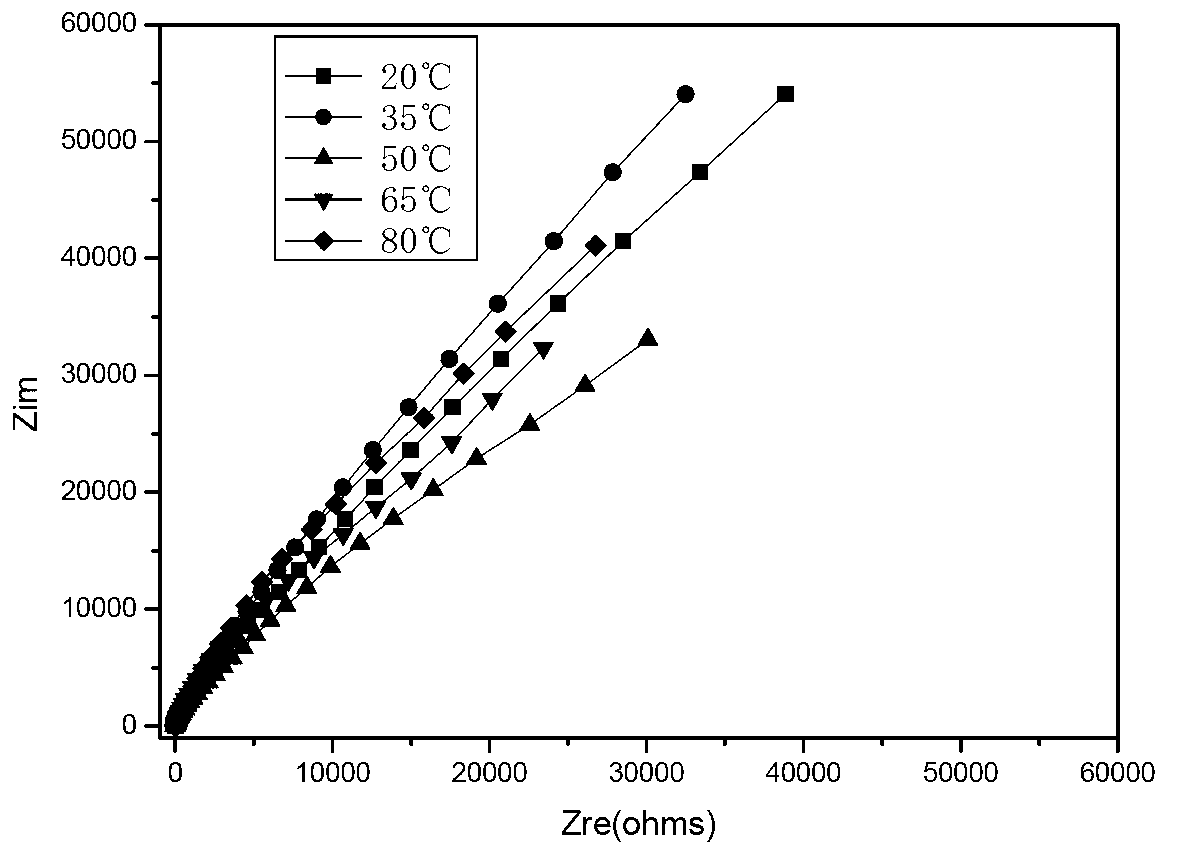

A gel polymer, electrolyte film technology, used in circuits, electrical components, secondary batteries, etc., can solve problems such as limited compatibility, differences in molecular structure, ionic conduction does not play any role, and achieve good mechanical properties, The effect of suppressing precipitation and high room temperature ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Mix 80g of PEG800 with 27.5g of MDI, raise the temperature at 75°C, and react for 7 hours to form a prepolymer. Then, the temperature was adjusted to 75° C., 2.4 g of LiOH was gradually added to the reaction system, and the reaction was carried out for 4 hours to obtain a polyether-type polyurethane lithium salt.

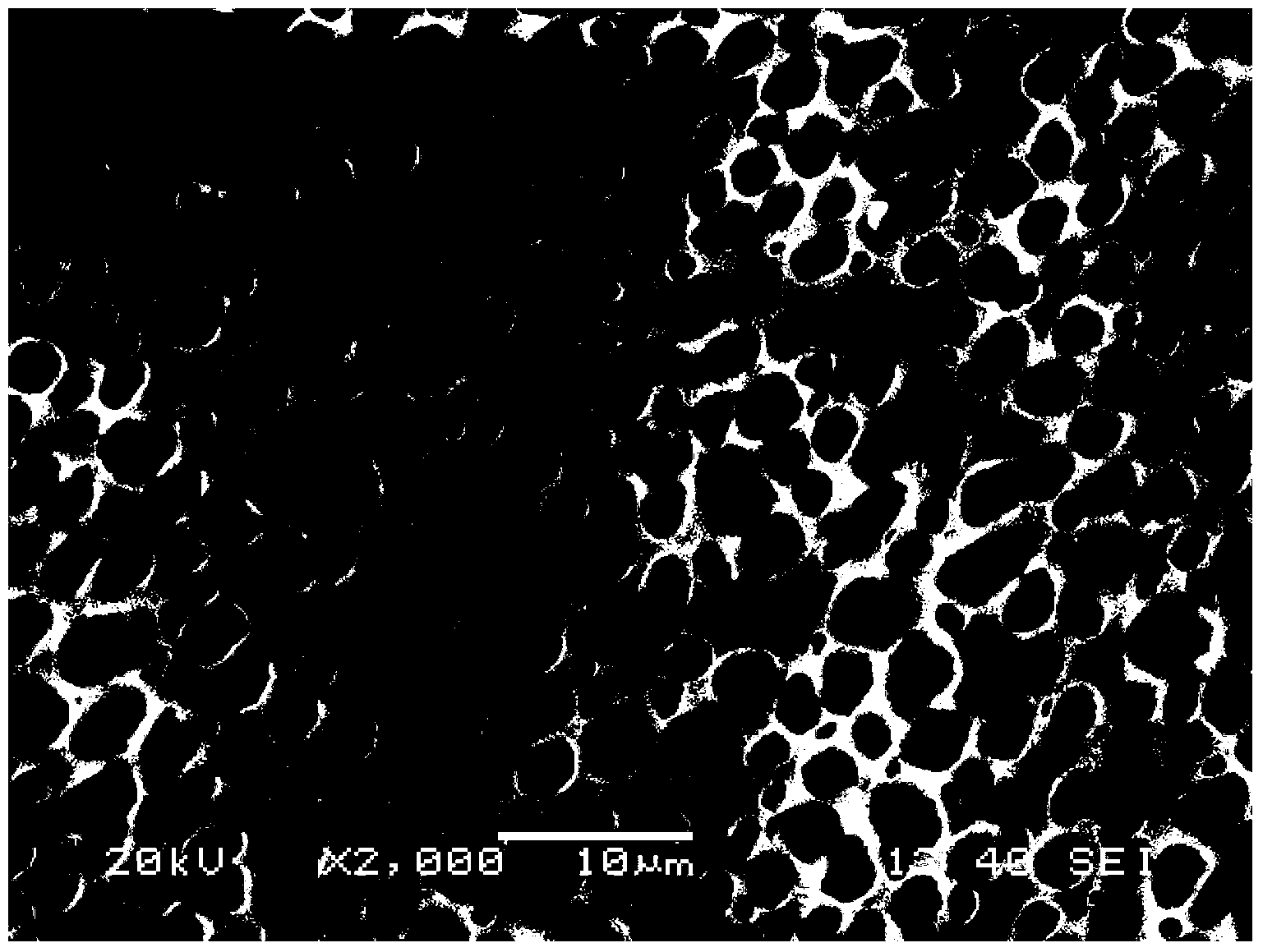

[0019] (2) 5g of PVDF powder with molecular weight of Mn=1×105 was added to 60ml of the mixed solution of DMF and glycerol in a volume ratio of 8:1. After stirring at room temperature for 12 hours, 1g of polyether-type polyurethane lithium salt was added and then stirred. 12 hours to complete dissolution. The polymer solution was left to stand for debubbling, and then flatly spread on a glass plate with a spatula, and then dried in an oven at 110 °C for 24 hours. The porous morphology based polyether polyurethane lithium salt blend was prepared by thermally induced phase separation method. PVDF film.

[0020] (3) The polyether polyurethane lithium salt ...

Embodiment 2

[0025] (1) Mix 80g of PEG800 with 32.5g of MDI, raise the temperature at 90°C, and react for 5 hours to form a prepolymer. Then, the temperature was adjusted to 70° C., 7.2 g of LiOH was gradually added to the reaction system, and the reaction was carried out for 4.5 hours to obtain a polyether-type polyurethane lithium salt.

[0026] (2) 10g of PVDF powder with a molecular weight of Mn=1×106 was added to 110ml of a mixed solution of DMF and glycerol in a volume ratio of 8:1. After stirring at room temperature for 18 hours, 1g of polyether-type polyurethane lithium salt was added, and then Stir for 8 hours for complete dissolution. The polymer solution was left to stand for debubbling, and then flatly spread on a glass plate with a spatula, and then dried in an oven at 150 °C for 18 hours to prepare a polyether-polyurethane-based lithium salt blend with a porous morphology by a thermally induced phase separation method. PVDF film.

[0027] (3) The polyether polyurethane lith...

Embodiment 3

[0029] (1) Mix 80g of PEG800 with 30g of MDI, raise the temperature to 70°C, and react for 8 hours to form a prepolymer. Then, the temperature was adjusted to 65° C., 4.8 g of LiOH was gradually added to the reaction system, and the reaction was carried out for 5 hours to obtain a polyether-type polyurethane lithium salt.

[0030] (2) The molecular weight of 8g is M n =1×10 7 PVDF powder was added to a mixed solution of 90ml of DMF and glycerol in a volume ratio of 8:1. After stirring at room temperature for 15 hours, 1g of polyether-polyurethane lithium salt was added, and stirred for 6 hours until it was completely dissolved. The polymer solution was left to stand for debubbling, and then flatly coated on a glass plate with a spatula, and then dried in an oven at 120 °C for 20 hours to prepare a polyether-based polyurethane lithium salt blend with a porous morphology by a thermally induced phase separation method. PVDF film.

[0031] (3) The polyether polyurethane lithium s...

PUM

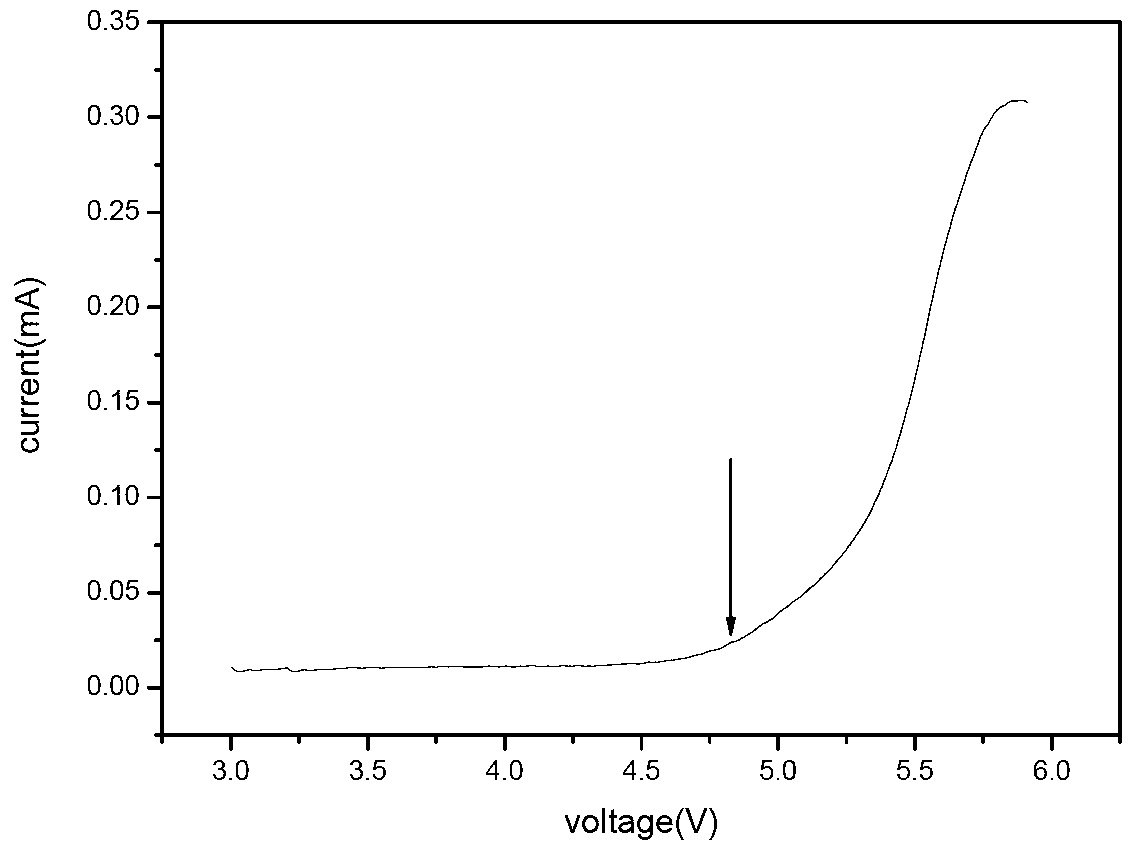

| Property | Measurement | Unit |

|---|---|---|

| electrochemical stability window | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com