Method for improving shear strength of nonmetal anti-floating anchor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

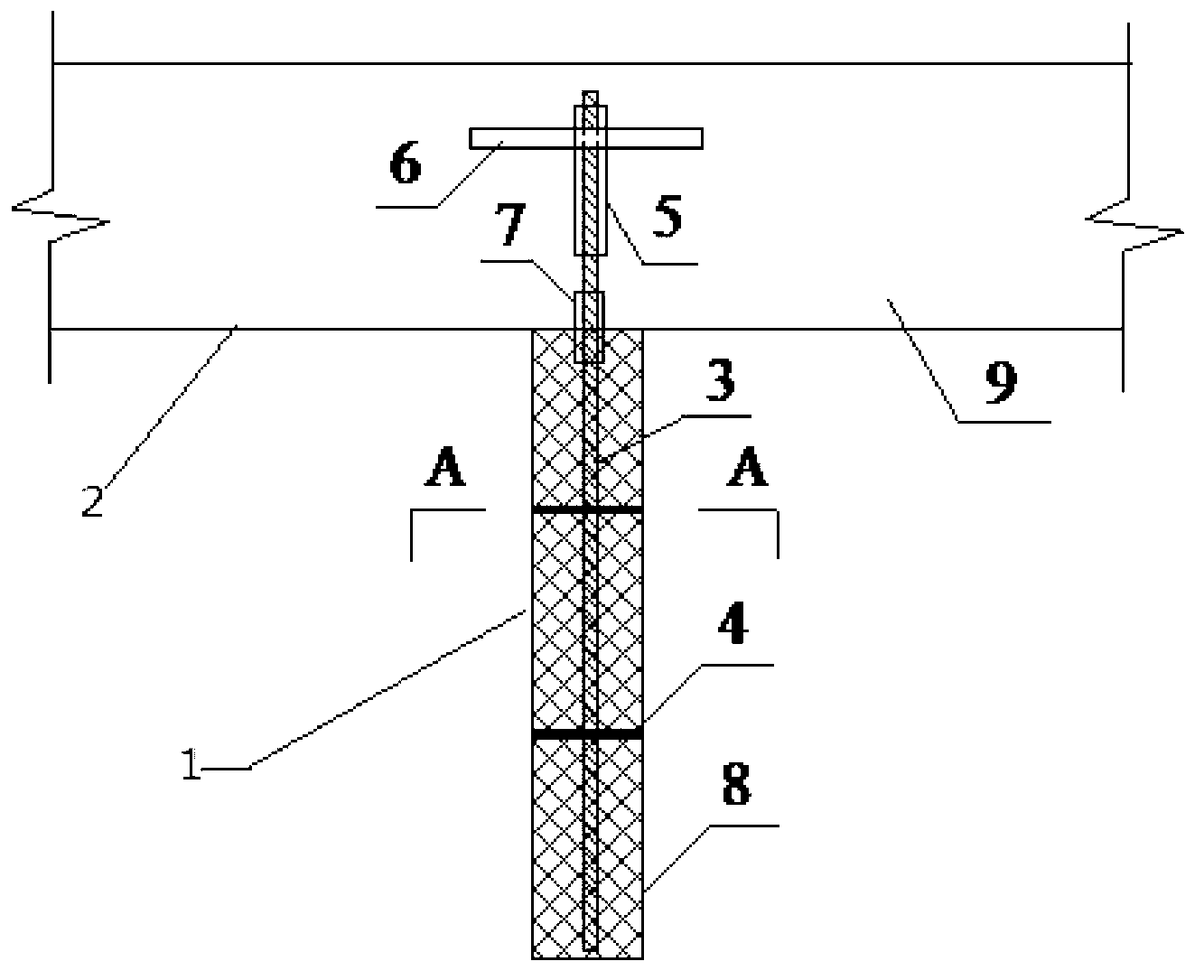

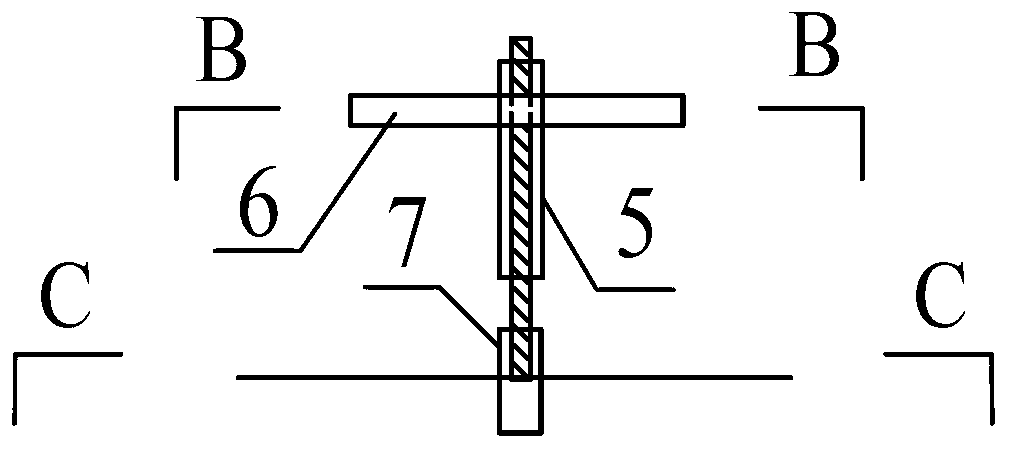

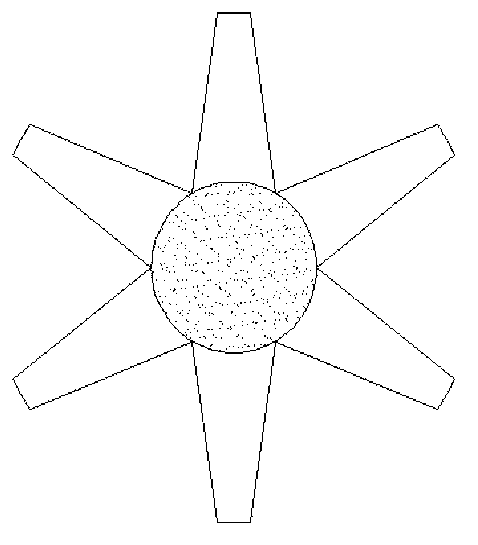

[0022] In this embodiment, first, according to the size requirements of the non-metallic anti-floating anchor, holes are drilled on the rock foundation to form the anchor hole 8, and the anchor hole 8 is as vertical as possible to the ground; the centering device 4 is installed at a certain distance. The distance between the outer surface of the anchor body 3 should be determined according to the length of the anchor section in the anchor body 3; the rigid arm 7 is inserted into the anchor body 3, and the rigid arm 7 is tightly bonded to the anchor body 3 through epoxy resin. The rigid arm 7 is fixed at the interface between the inner anchor section and the outer anchor section of the anchor body 3, and the dimensions of the inner and outer anchor sections of the rigid arm 7 are the same; insert the anchor rod with the centering device 4 and the rigid arm 7 into the anchor rod In the hole 8, feed it manually until the bottom end of the anchor rod reaches the bottom of the ancho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com