One-component addition type liquid silicone rubber and preparing method thereof

A technology of liquid silicone rubber and addition type, which is applied in the field of one-component addition type liquid silicone rubber and its preparation, can solve the problems of troublesome assembly, lack of adhesiveness, inconvenient use, etc., and achieves low cost and good mechanical properties. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

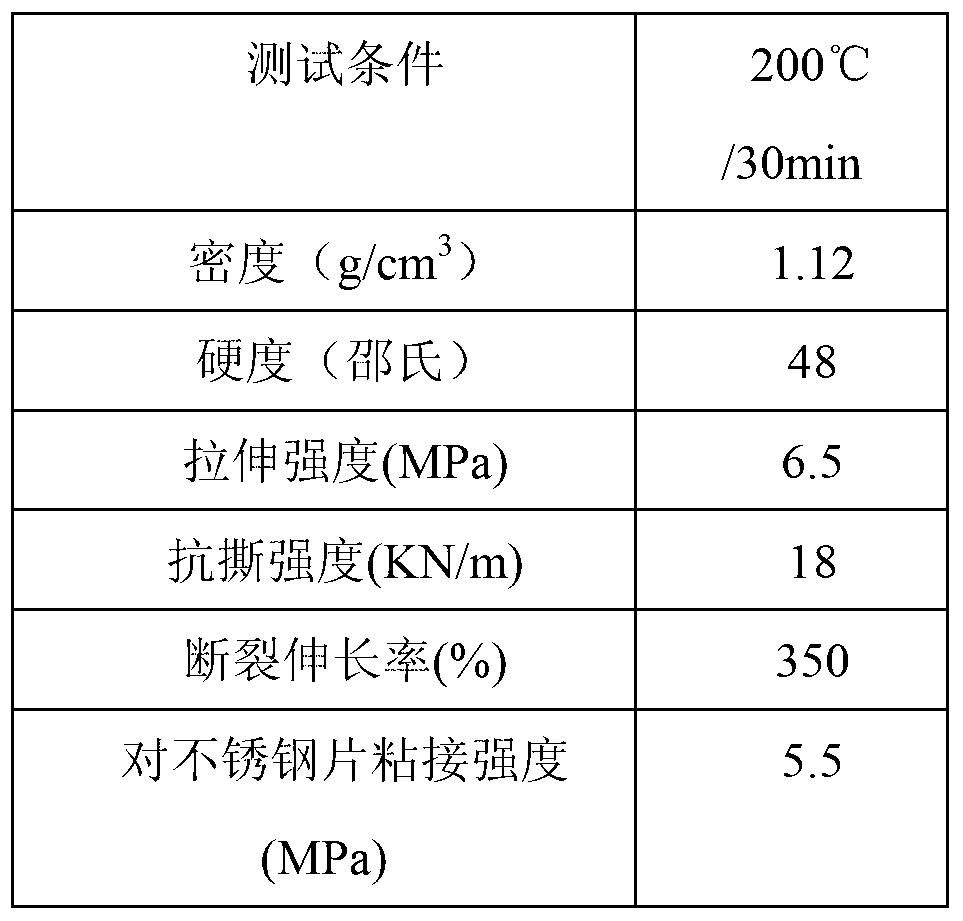

Examples

preparation example Construction

[0036] The preparation method of the polysiloxane II described in the embodiment is: from 100 parts by mass of octamethylcyclotetrasiloxane, 0.2 to 0.3 parts by mass of tetravinylmethyldivinyldisiloxane, in tetramethyl Under the catalysis of ammonium hydroxide, polymerize at a constant temperature of 100°C for 2.5 hours, then raise the temperature to 150°C to equilibrate for 1 hour, then raise the temperature to 180°C, and release low-molecular substances under a vacuum of 200 poises. The prepared viscosity is 8000~ 10000cp, vinyl-terminated organopolysiloxane with a vinyl content of 2.5-5.0mol.%.

[0037] The platinum-gold complex is coordinated and synthesized by chloroplatinic acid and isopropanol, and the platinum content therein is 500-3000ppm. The preparation method of the platinum complex described in the examples is as follows: add 5 grams of chloroplatinic acid hydrate and 200 ml of isopropanol into a 500 ml four-necked flask, and heat up and reflux for 1 hour under n...

Embodiment 1

[0050] a. Preparation of base glue

[0051] ①In a 500L kneader, add 140kg of polysiloxane I with a viscosity of 1000cp (25°C) and a vinyl content of 1.2mol.%, and 100kg of fumed silica treated with a silane coupling agent for hydrophobic treatment, and knead it into Continue kneading at room temperature for 1 hour after dough;

[0052] ②Raise the temperature to 150-160°C, then knead at constant temperature for 1 hour;

[0053] ③ Vacuumize to a vacuum degree of 0.8MPa, continue kneading at 150-160°C for 3 hours under vacuum conditions, then stop vacuuming, cool down to 120°C, add 100kg with a viscosity of 1000cp (25°C) and vinyl content of 1.2mol .% polysiloxane I and 16kg of polysiloxane II with a viscosity of 10000cp (25°C) and a vinyl content of 5.0mol.%, mixed evenly to obtain the base glue;

[0054] b. Preparation of one-component addition type liquid silicone rubber

[0055] In a 300L planetary mixer, add 200kg of the base glue prepared above, 4.5kg of prepared hydroge...

Embodiment 2

[0061] a. Preparation of base glue

[0062] ①In a 500L kneader, add 140kg of polysiloxane I with a viscosity of 1000cp (25°C) and a vinyl content of 1.2mol.%, and 100kg of fumed silica treated with a silane coupling agent for hydrophobic treatment, and knead it into Continue kneading at room temperature for 1 hour after dough;

[0063] ②Raise the temperature to 150-160°C, then knead at constant temperature for 1 hour;

[0064] ③ Vacuumize to a vacuum degree of 0.8MPa, continue kneading at 150-160°C for 3 hours under vacuum conditions, then stop vacuuming, cool down to 120°C, add 80kg .% polysiloxane I and 36kg of polysiloxane II with a viscosity of 10000cp (25°C) and a vinyl content of 5.0mol.%, mixed evenly to obtain the base glue;

[0065] b. Preparation of one-component glue

[0066] In a 300L planetary mixer, add 200kg of the base glue prepared above, 6.2kg of prepared hydrogen-containing polysiloxane and 0.08kg of acetylenic alcohol inhibitors, stir and mix for 30min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com