Preparation method of polyester substance, polyester substance, polyester chip and polyester film

A technology of polyester chips and polyester products, applied in the field of polyester materials, can solve the problems of low catalyst activity, affecting film quality, and failing to meet the requirements of optical films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

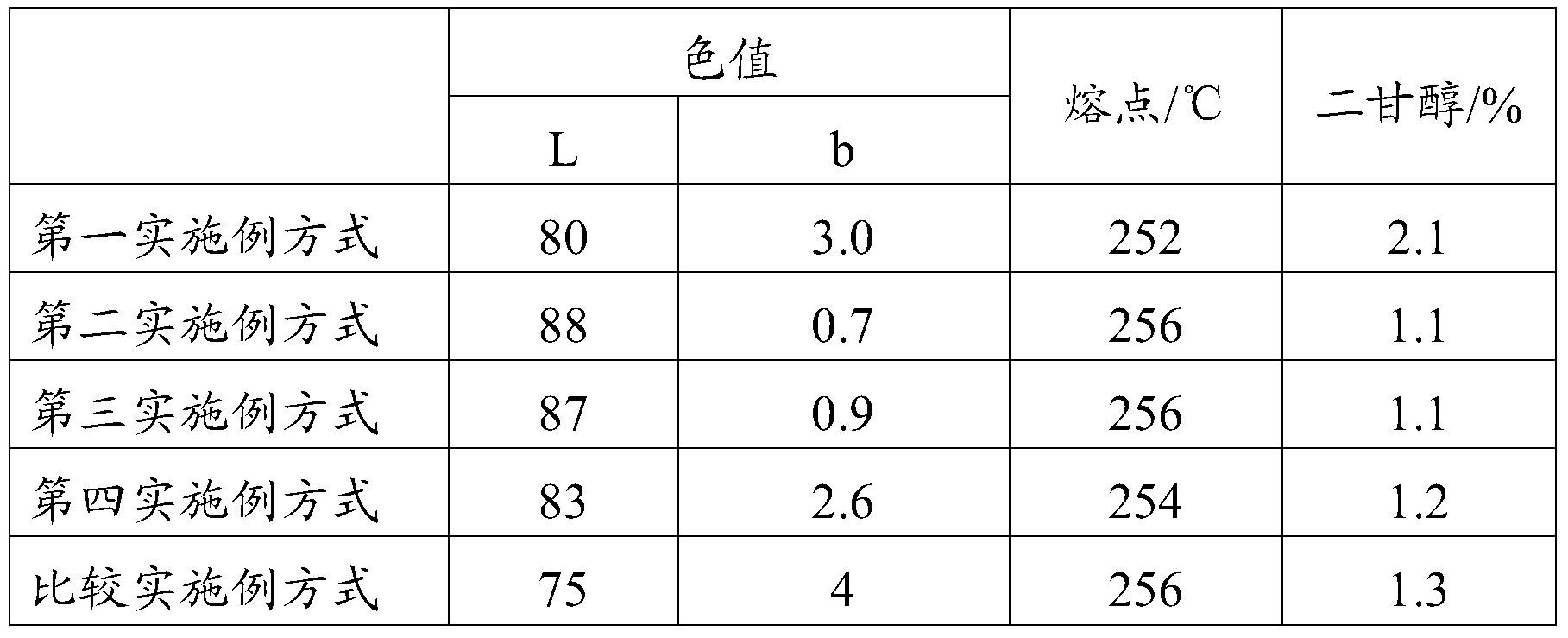

Examples

preparation example Construction

[0028] The embodiment of the present invention discloses a preparation method of a polyester product, the operation steps of which are as follows:

[0029] a) Mix the acid component and the alcohol component, and carry out esterification or transesterification to obtain an esterified product;

[0030] b) subjecting the esterified product obtained in step a) to a polycondensation reaction under the action of a catalytic system;

[0031] c) obtaining a polyester product from step b);

[0032] in,

[0033] The catalytic system adopts germanium dioxide catalyst, and the germanium dioxide is tetragonal or hexagonal or amorphous.

[0034] Preferably, relative to tetragonal or hexagonal germanium dioxide, the refractive index of the polyester is closest to that of amorphous germanium dioxide.

[0035]Preferably, the refractive index of the polyester is in the range of 1.61-1.64, specifically, the refractive index of the polyester is 1.62.

[0036] Preferably, the concentration ra...

no. 1 example approach

[0049] A kind of preparation method of polyester thing, its operating steps are specifically as follows:

[0050] First, 0.3g of amorphous germanium dioxide (purity: 99.99%) was evenly dispersed in 1Kg of ethylene glycol (fiber grade), and then 8.6Kg of terephthalic acid (fiber grade), 3.02Kg of ethylene glycol ( Fiber grade), 2.3g trimethyl phosphate (reagent grade), put the above materials into a polymerization reactor with a capacity of 20L.

[0051] After feeding the materials, start stirring, and replace the air in the polymerization reactor with nitrogen to ensure that the reaction atmosphere is always under the protection of nitrogen. First, start the esterification reaction, control the esterification reaction temperature to 230°C, and the esterification reaction pressure to 250Kpa. During the esterification reaction, try to ensure the normal water outlet of the cooling tower and avoid forced reflux. When the actual water output reaches or exceeds the theoretical valu...

no. 2 example approach

[0055] A kind of preparation method of polyester thing, its operating steps are specifically as follows:

[0056] First, 1.5g of amorphous germanium dioxide (purity: 99.99%) was evenly dispersed in 1Kg of ethylene glycol (fiber grade), and then 8.6Kg of terephthalic acid (fiber grade), 3.02Kg of ethylene glycol ( Fiber grade), 2.3g trimethyl phosphate (reagent grade), put the above materials into a polymerization reactor with a capacity of 20L; the rest of the preparation steps are the same as those in the first embodiment.

[0057] The method of the polyester chip and the polyester film in the second embodiment can also be the same as the first embodiment, and the obtained polyester film is especially suitable for manufacturing optical films.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com