Polypropylene modified functional film and preparation method thereof

A technology of polypropylene film and polypropylene, which is applied in the field of surface modification and functionalization of all-light control polypropylene film, which can solve the problems of complex operation, high requirements for the reaction process, and easy peeling off of the surface coating, and achieve simple process , Improving the effect of hydrophilicity and antifouling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

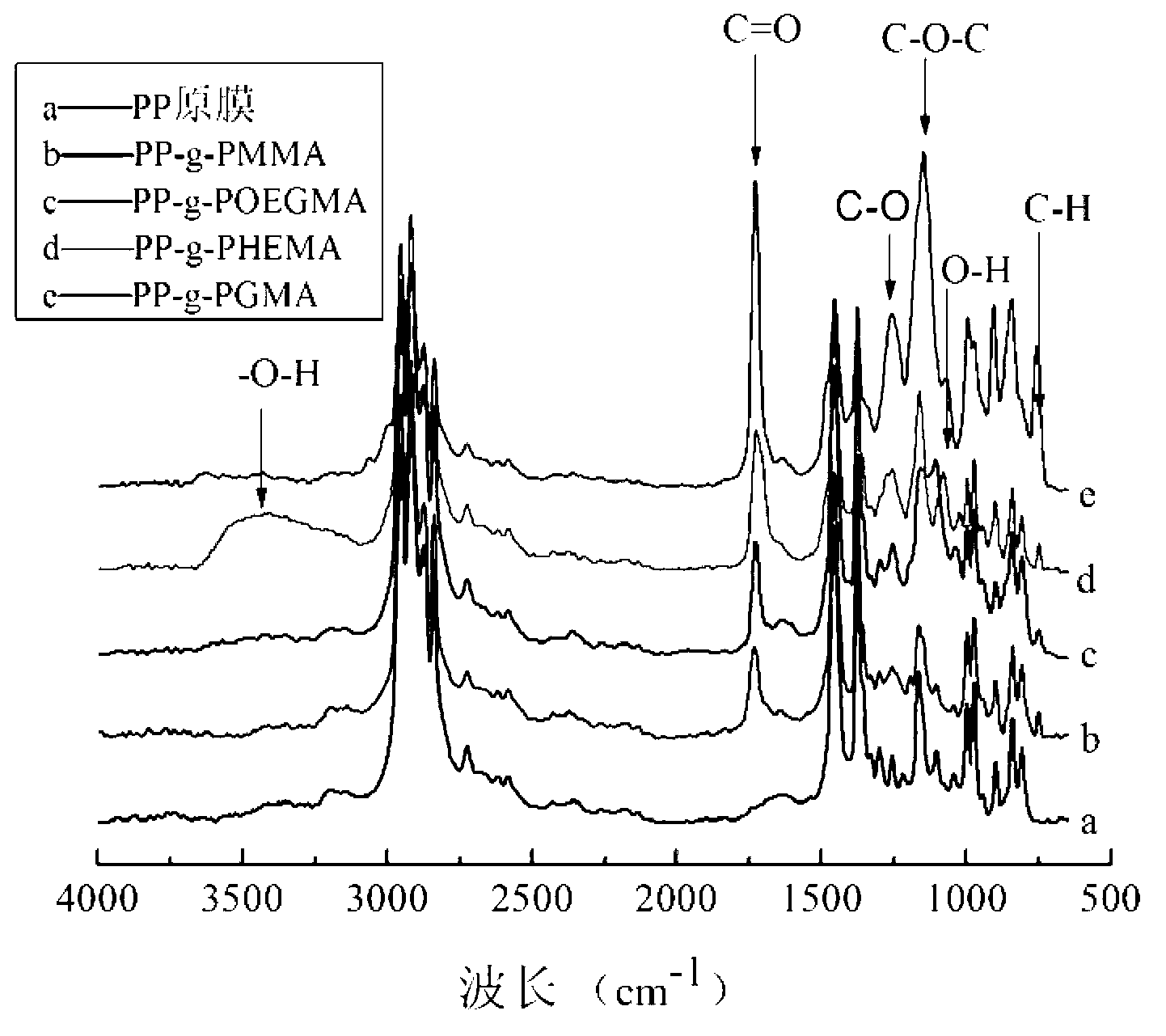

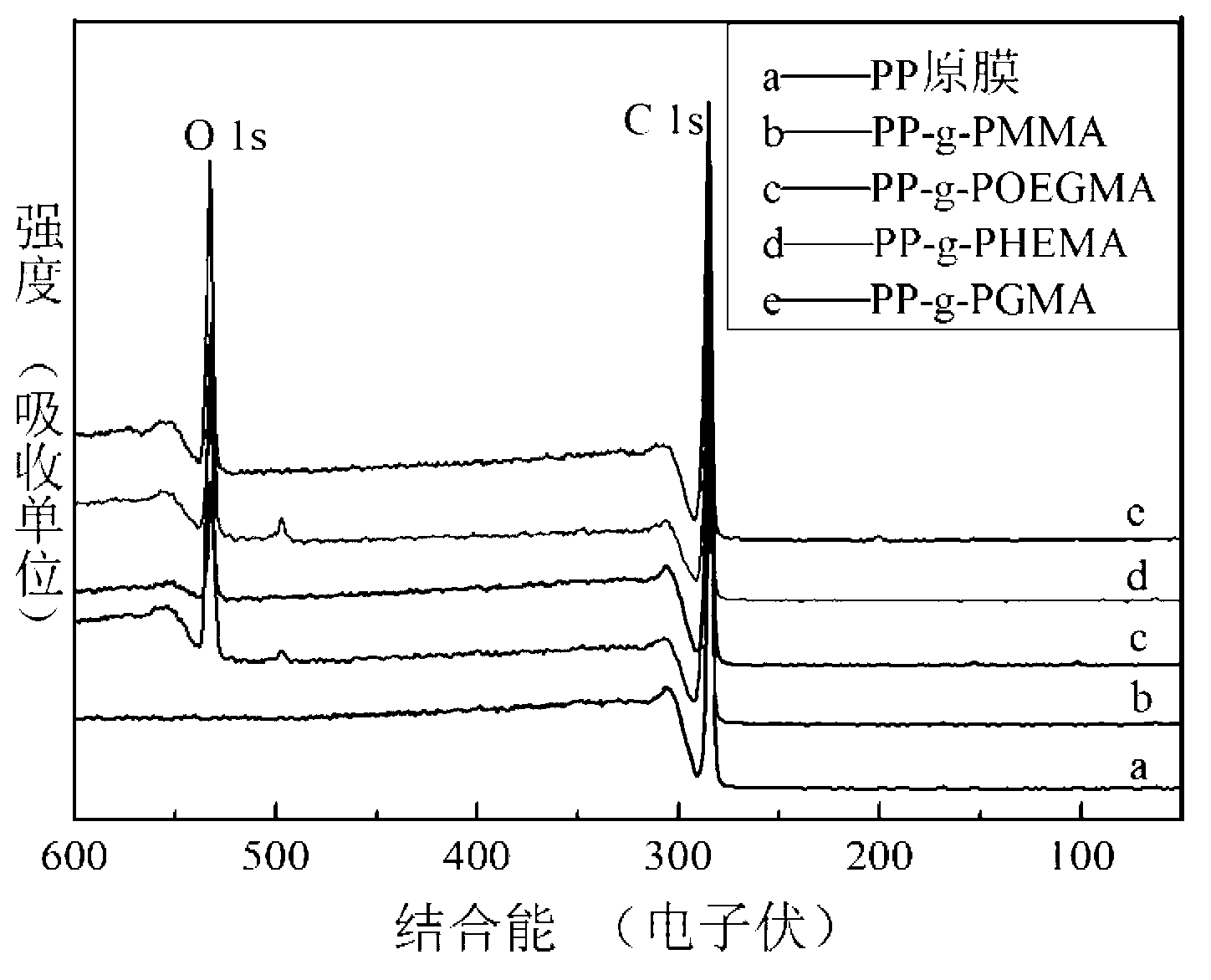

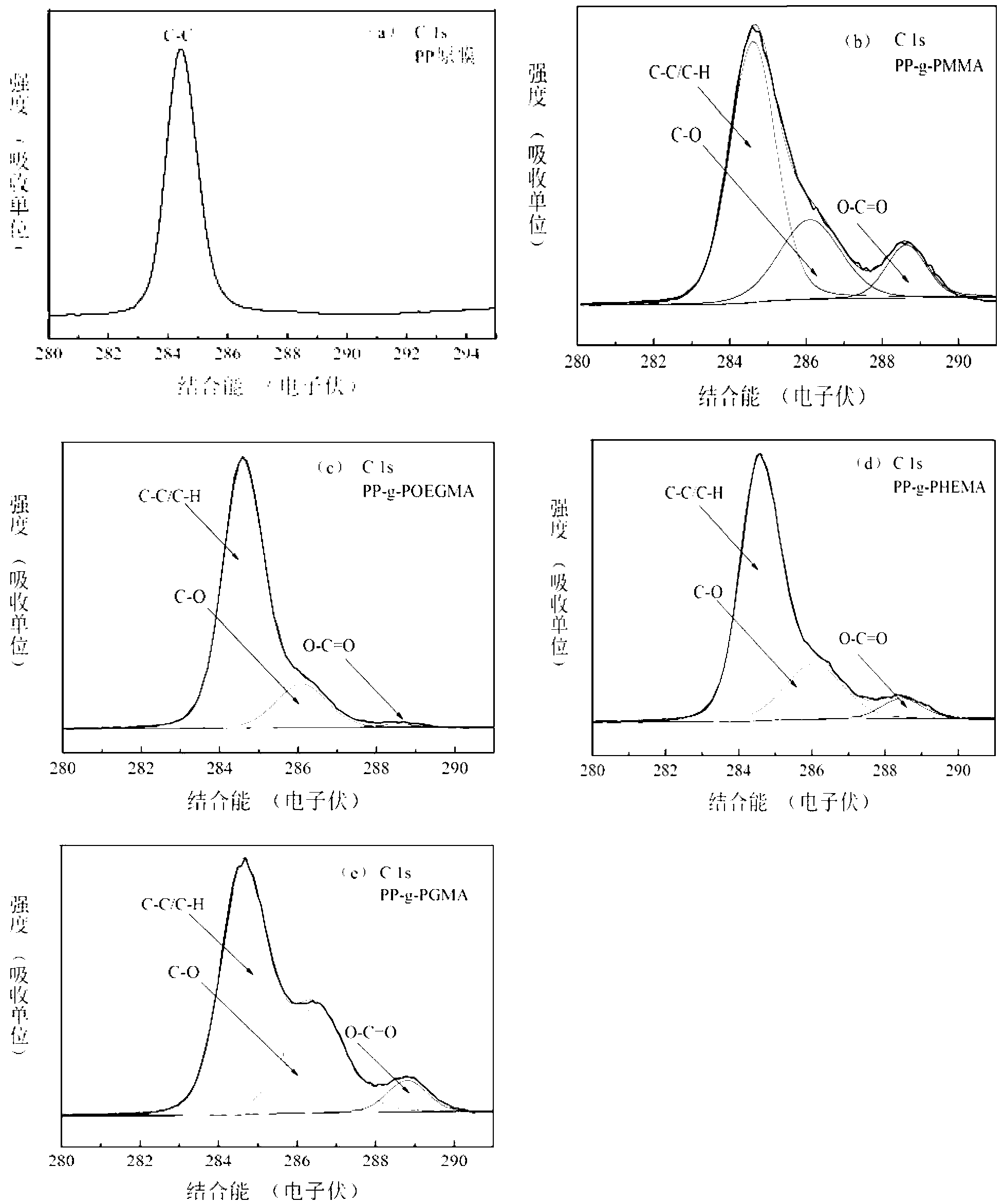

[0055] Polypropylene modified functional film, which is grafted with poly(polyethylene glycol) methacrylate on the surface of polypropylene film by a complete light control method.

Embodiment 2

[0057] Polypropylene modified functional film, the film is grafted with polymethyl methacrylate on the surface of the polypropylene film through the method of complete light control.

Embodiment 3

[0059] Polypropylene modified functional film, the film is grafted with polyglycidyl methacrylate on the surface of the polypropylene film through the method of complete light control.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com