Processing technology of low-quality flue cured tobacco leaf

A technology for processing and treating tobacco leaves, which is applied in the fields of tobacco, tobacco preparation, and application, can solve the problems of high processing intensity, single process parameter setting, and reduced tobacco leaf quality, and achieves reduction of process temperature, flexible selection of process parameters, The effect of improving the processing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 400kg of low-quality flue-cured tobacco leaves, the processing techniques of which include:

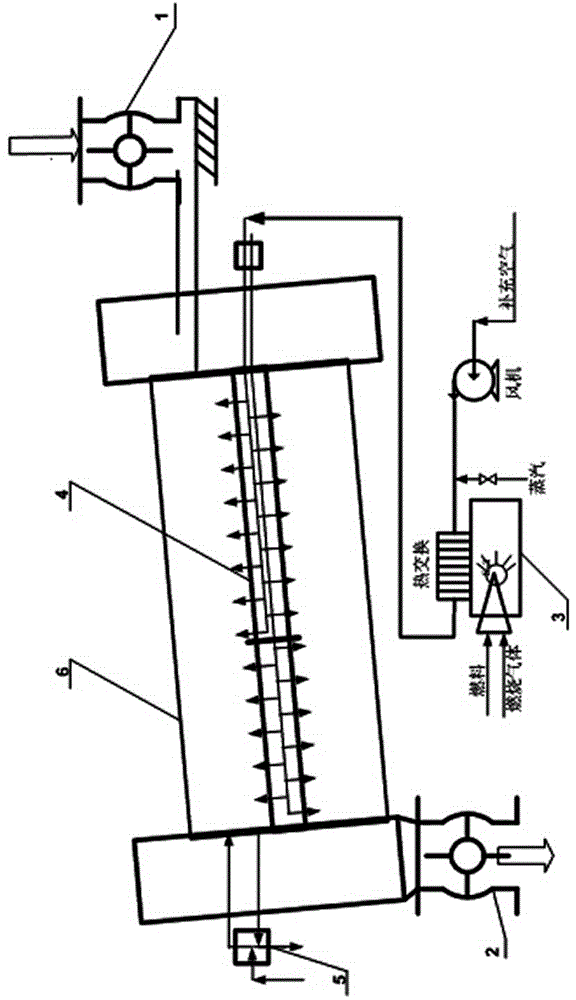

[0036] 1 loose slice shredded, and concrete process step is: 1. tobacco leaf is delivered in the loose moistening machine and carries out temperature increase and humidification. Among them, the material flow rate is set to 500kg / h before loosening and regaining moisture, the hot air temperature is set to 50°C, the moisture content of the tobacco sheet is set to 17% after moisture regaining, and the temperature of the smoke sheet is set to 50°C±3°C. ② Feeding of tobacco sheets: Use the rear-end feeding device of the loose moisture conditioner to add humectants and other components to the feed liquid to improve the processing resistance of tobacco leaves. The feed-liquid addition ratio is 1%. ③Slicing: Send the loosened tobacco slices to the shredding machine for shredding. Wherein, the shredded width and length are set to 1.0 mm, and the shredded length is set to 40 mm.

[0...

Embodiment 2

[0042] 500kg of low-quality flue-cured tobacco leaves, the processing techniques of which include:

[0043] 1 loose slice shredded, and concrete process step is: 1. tobacco leaf is delivered in the loose moistening machine and carries out temperature increase and humidification. Among them, the material flow rate is set to 500kg / h before loosening and regaining moisture, the hot air temperature is set to 50°C, the moisture content of the tobacco sheet is set to 18% after moisture regaining, and the temperature of the smoke sheet is set to 50°C±3°C. ② Feeding of tobacco sheets: Use the rear-end feeding device of the loose moisture conditioner to add humectants and other components to the feed liquid to improve the processing resistance of tobacco leaves. The feed ratio of feed liquid is 3%. ③Slicing: Send the loosened tobacco slices to the shredding machine for shredding. Wherein, the shredded width and length are set to 1.0 mm, and the shredded length is set to 40 mm.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com