Terminal tongue and manufacturing method thereof

A manufacturing method and tab technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, hybrid/electric double layer capacitor manufacturing, etc., can solve problems such as short circuit and inability to ensure insulation, and achieve the effect of high-efficiency manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

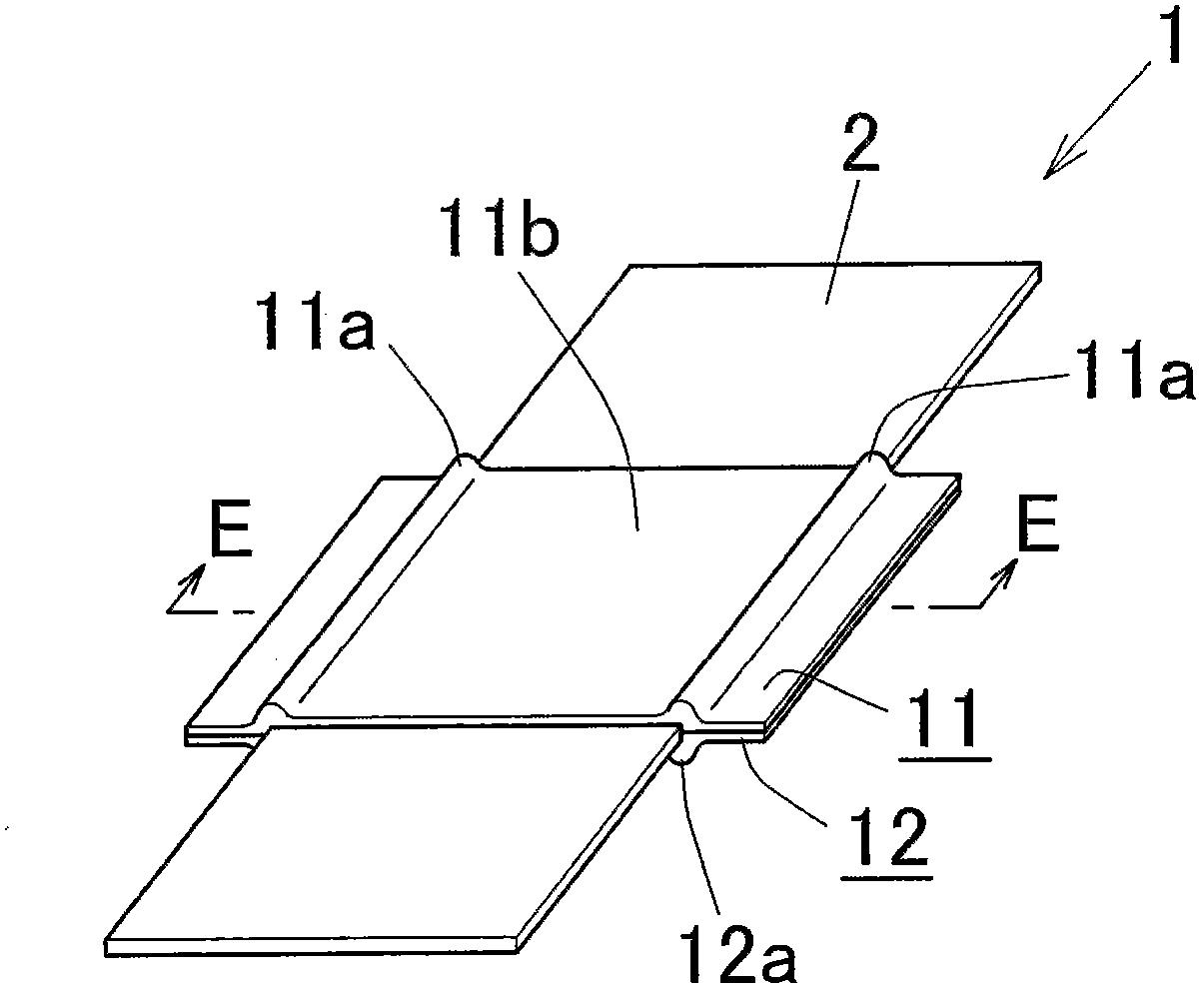

[0134] Prepare a metal plate (length 50 mm x width 50 mm) 2 formed by applying 2 μm thick nickel plating on the surface of a 200 μm thick copper plate, and two resin insulating films 11, 70 mm long x 10 mm wide x 100 μm thick. 12 (see Figure 4 ).

[0135] In addition, a pair of upper and lower heated and pressurized molds 30 are prepared. The heated and pressurized molds 30 are laminated and integrated with a substantially plate-shaped metal hard body 31 by laminating resin sheets 33 made of fluorinated vinyl resin with a rubber hardness of 60 degrees. formed on one side (see Figure 4 ). On the non-laminated surface of the resin sheet 33 (the surface that comes into contact with the insulating film during hot pressing), a concave portion 34 having substantially the same shape as the insulating film in plan view is formed.

[0136] Next, the above-mentioned insulating films 11 and 12 are placed on both sides of the above-mentioned metal plate 2 so as to cover a part of the...

Embodiment 2

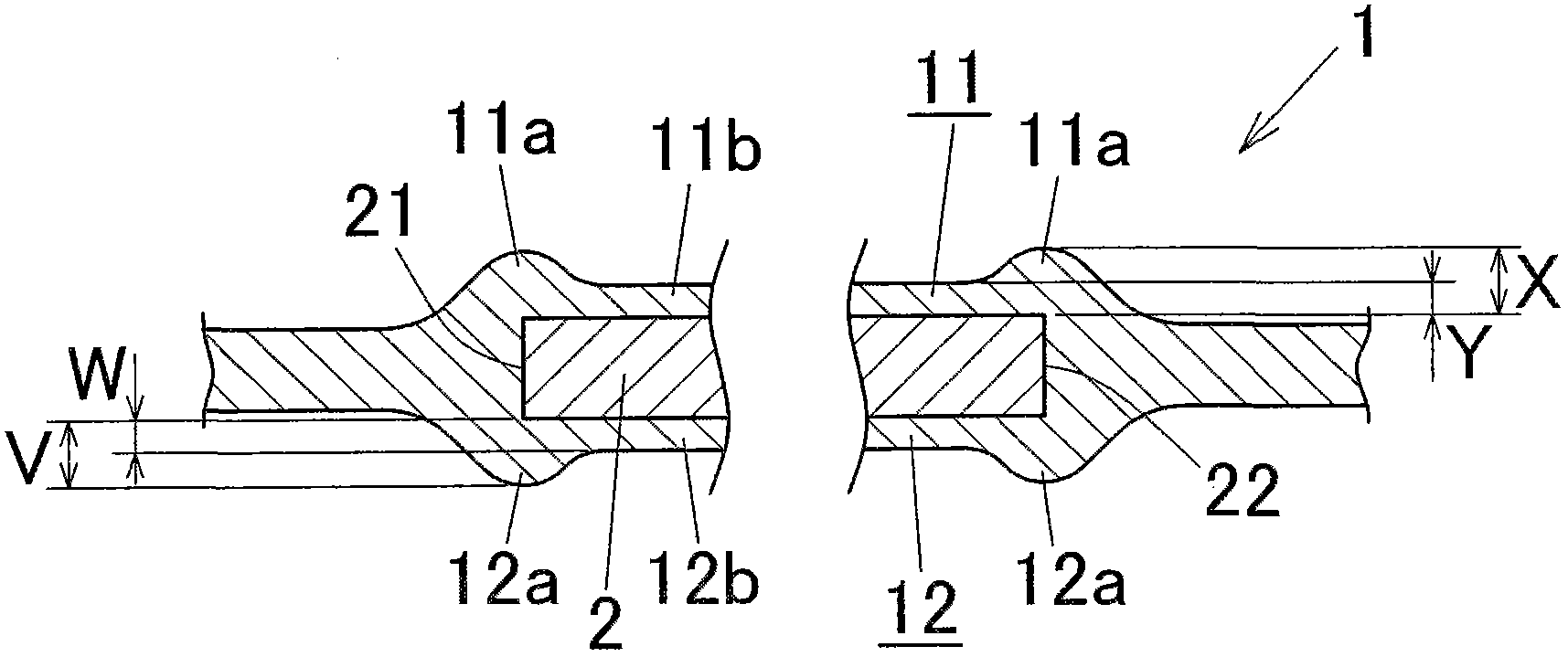

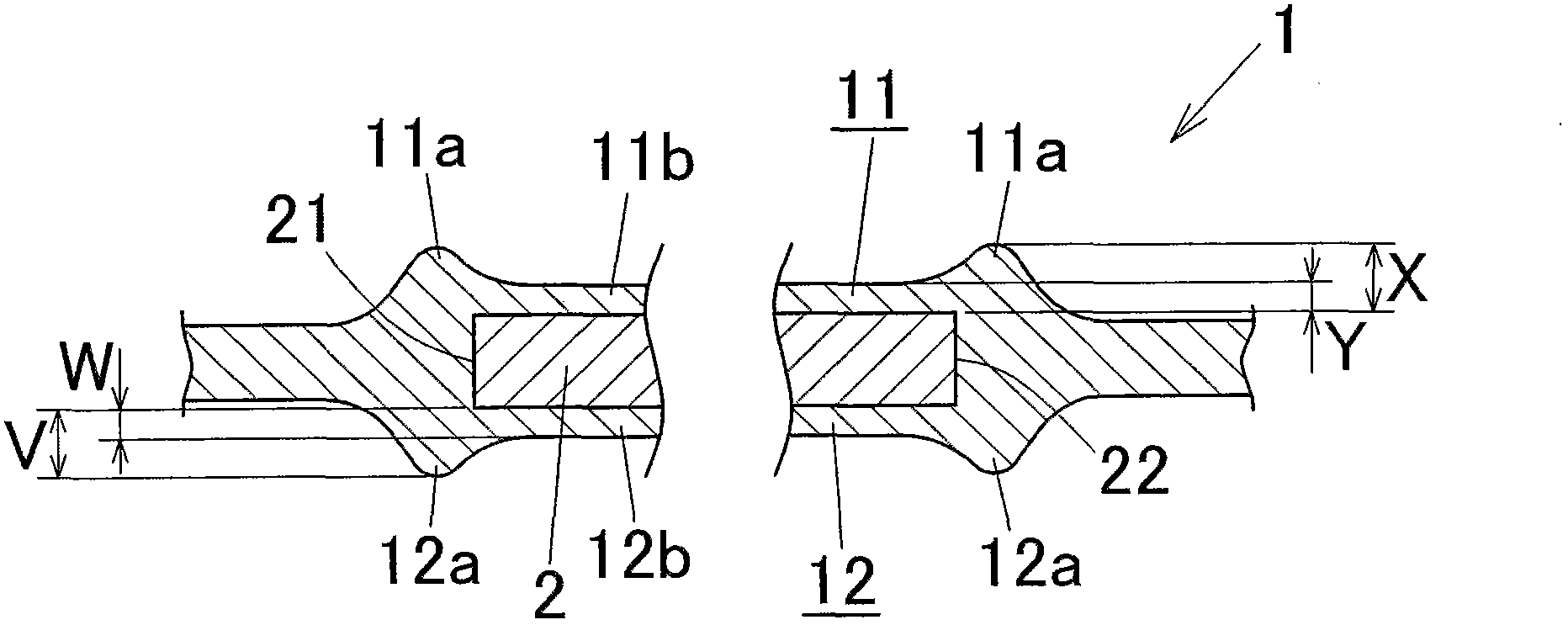

[0139] The temperature of the heating and pressing mold during hot pressing is 210°C, the pressing pressure applied by the heating and pressing mold is 1000N, and the hot pressing time is set to 7 seconds, except that it is the same as Example 1, thus obtaining image 3 Tab 1 of the structure shown.

[0140] An optical microscope photograph of the cross-section of the obtained tab 1 was taken, and the enlarged image revealed that the first swelling rate was 50%, and the second swelling rate was 50%.

Embodiment 3

[0142] The temperature of the heating and pressing mold during hot pressing is 240° C., the pressing pressure applied by the heating and pressing mold is 1000 N, and the hot pressing time is set to 7 seconds, except that it is the same as Example 1, thus obtaining image 3 Tab 1 of the structure shown.

[0143] An optical microscope photograph of the cross-section of the obtained tab 1 was taken, and the enlarged image showed that the first swelling rate was 90%, and the second swelling rate was 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rubber hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com