Manufacturing method and application for phosphorous composition coated nanometer silicon slurry

A technology of nano-silicon and composition, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of difficult to achieve the best effect, affect the photoelectric conversion efficiency of the light-receiving area, and affect the current of the silver grid line. Export efficiency and other issues, to achieve the effect of high adhesion, high line definition, and prevention of nano-silicon oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

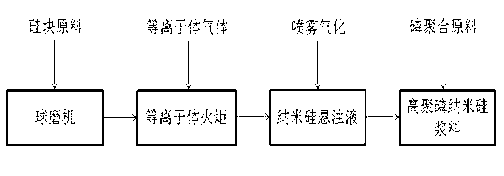

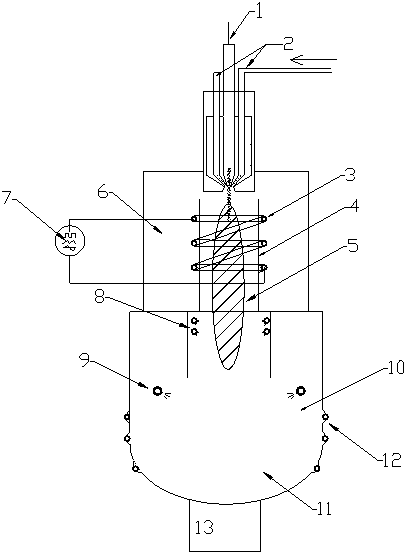

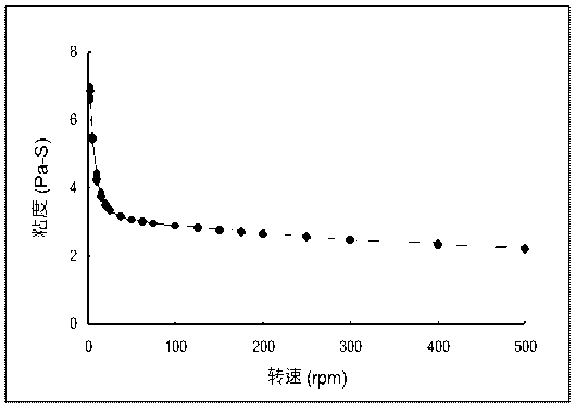

[0032] Preparation: use a high-energy ball mill to grind the silicon material for 1 hour to obtain small silicon particles of 10-100 microns; vacuumize the system and fill it with argon. After several cycles, the system is argon atmosphere. Adjust the working gas pressure of the system between 0.1-0.5MPa. Turn on the power supply of the plasma generator, the power is 100 kilowatts, the frequency is 10 MHz, and the voltage and current are adjusted in the range of 100-200V and 50-200A respectively to stabilize the plasma torch; start the powder feeder and use the argon flow to The speed of 200 grams of silicon powder per hour brings micron-sized silicon particles into the plasma torch, and forms nano-silicon with a particle size of 10-100 nm through gasification, nucleation, and growth steps. When the temperature drops to 60-120 o At C, spray the solution at a rate of 900 grams per hour to collect the powder. The powder collection solution is mixed with 1:1 hexamethyldisiloxan...

Embodiment 2

[0035] Preparation: Use a high-energy ball mill to grind silicon particles for 1-4 hours to obtain small silicon particles with a size of 10-100 microns; prepare nano-scale silicon powder: vacuumize the system and fill it with argon. After several cycles, the system is argon atmosphere. Adjust the working gas pressure of the system between 0.1-0.5MPa. Turn on the power supply of the plasma generator, the power is 100 kilowatts, the frequency is 10 MHz, and the voltage and current are adjusted in the range of 100-200V and 50-200A respectively to stabilize the plasma torch; start the powder feeder and use the argon flow to The speed of 100 grams of silicon powder per hour brings micron-sized silicon particles into the plasma torch, and forms nano-silicon with a particle size of 10-100nm through gasification, nucleation, and growth steps. When the temperature drops to 60-120 oAt C, spray the solution at a speed of 900 grams per hour to collect the powder. The powder collection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com