Anti-bacterial finishing agent for textiles

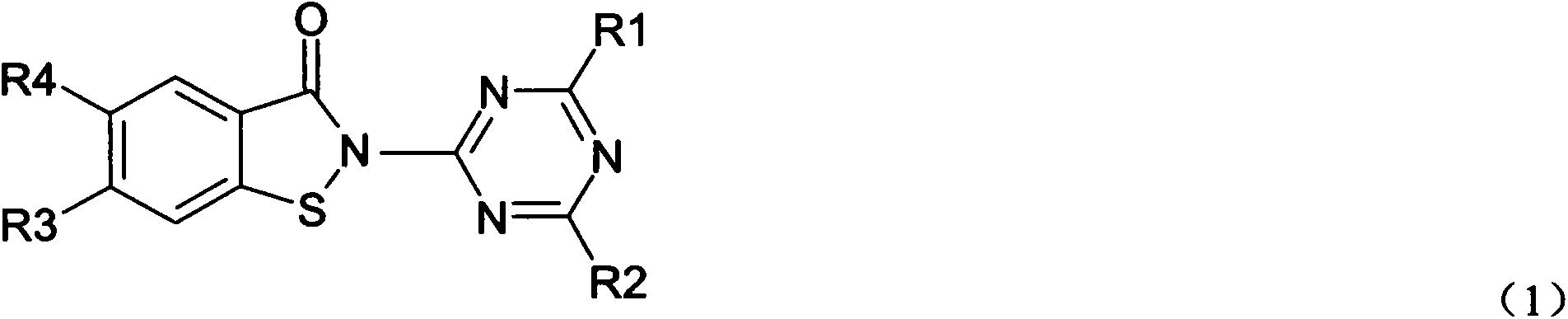

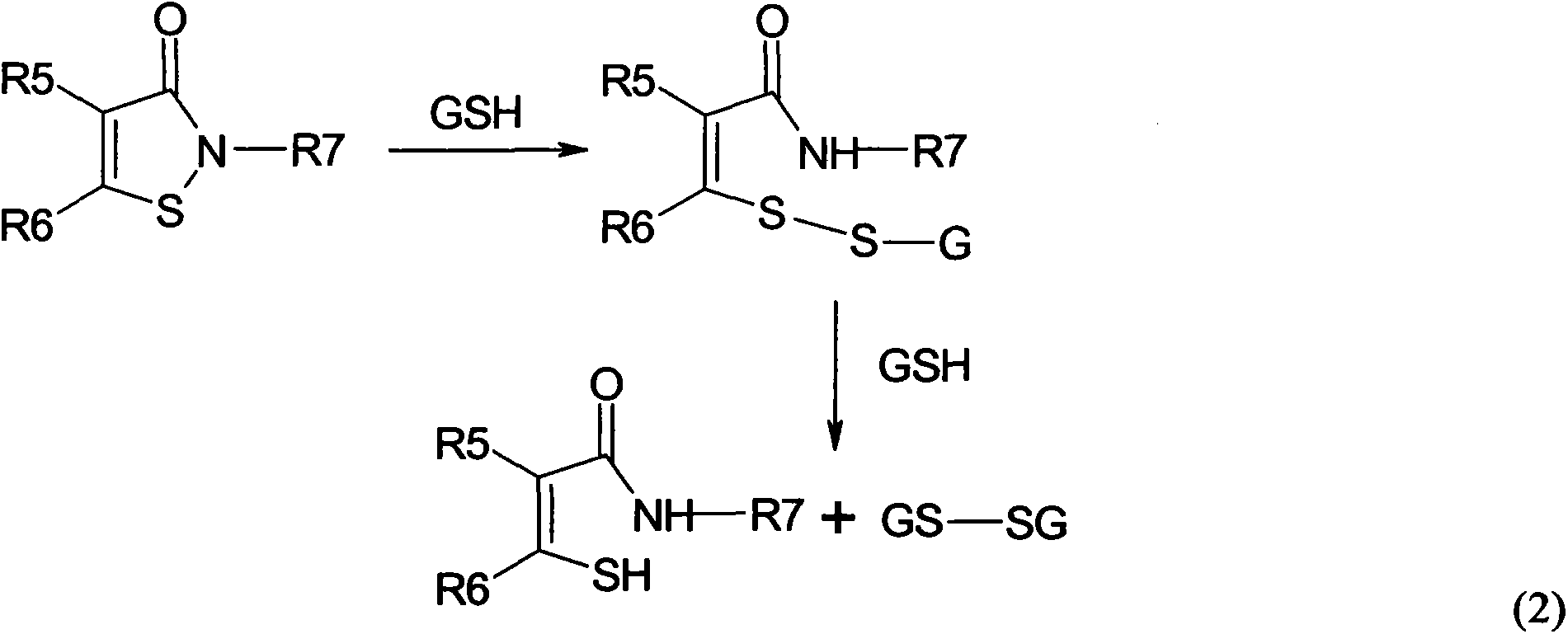

An antibacterial finishing agent and antibacterial finishing technology, applied in textiles and papermaking, fiber treatment, organic chemistry, etc., can solve the problems of poor affinity of cellulose fibers, less application, and easy washing off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

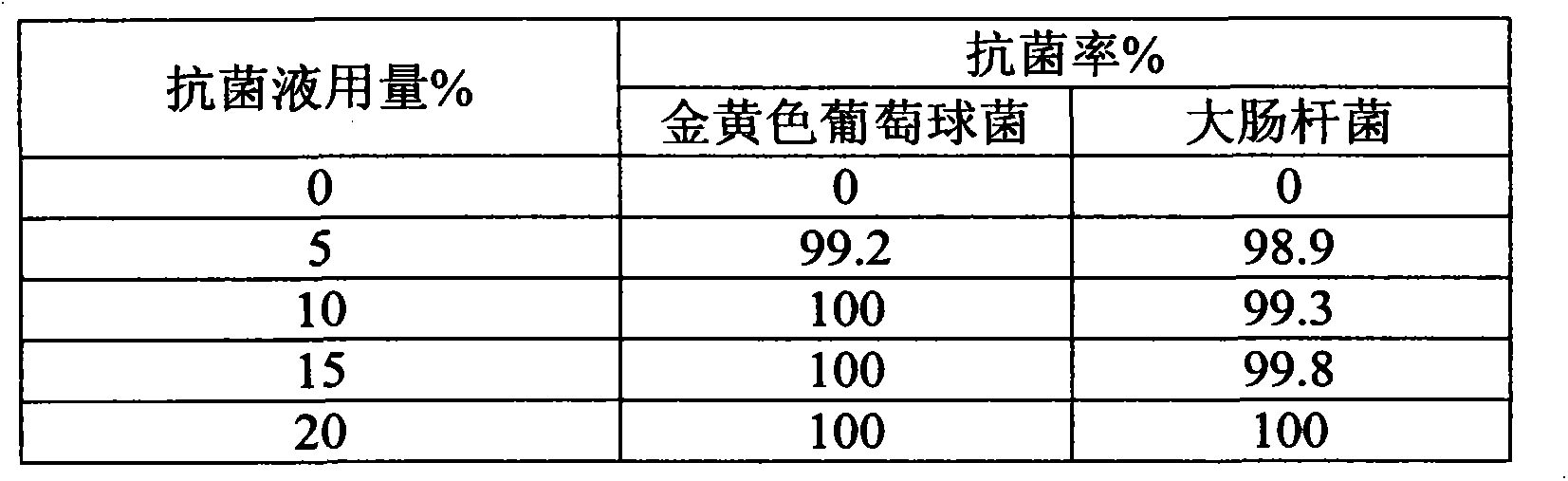

[0022] In a 500mL four-neck flask equipped with an electric stirrer and a thermometer, add 7.5g of benzisothiazolinone and 150mL of chloroform, stir to dissolve, cool to 0-5°C, and dropwise add 100mL of cyanuric chloride in chloroform ( Which contains cyanuric chloride 11.5g), after the dropwise addition, react at room temperature for 1h, pour the reaction solution into a separatory funnel, wash 3 times with distilled water, add anhydrous sodium sulfate to dry overnight, filter to remove sodium sulfate , Distilled under reduced pressure to obtain a white solid, which is a reactive benzisothiazolinone fungicide, and the product yield is 94.6%.

[0023] Add an appropriate amount of the antibacterial agent obtained in the first step, 3 g of nonylphenol polyoxyethylene ether, and 2.5 g of polyoxyethylene ether sorbitan ester into 95 g of deionized water to prepare an emulsified working solution. According to the liquor ratio of 1:15, the pure cotton white knitted fabric was impreg...

Embodiment 2

[0033] In a 500mL four-neck flask equipped with an electric stirrer and a thermometer, add 7.5g of benzisothiazolinone and 150mL of chloroform, stir and heat to dissolve, raise the temperature to 40°C, and drop 55g / L of 1-amino 3 , 180mL of chloroform solution of 5 dichloro-s-triazine, after the dropwise addition, react at 40°C for 2h, pour the reaction solution into a separatory funnel, wash with distilled water 3 times, add anhydrous sodium sulfate to dry overnight, filter The sodium sulfate was removed, and a white solid was obtained by distillation under reduced pressure, which was a reactive benzisothiazolinone bactericide, and the product yield was 86.4%.

[0034] Add 12g of the antibacterial agent obtained in the first step, 3.5g of nonylphenol polyoxyethylene ether, and 3.5g of polyoxyethylene ether sorbitan ester into 90g of deionized water to prepare an emulsified working solution. According to the liquor ratio of 1:15, the pure cotton white knitted fabric was impreg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com