High-strength steel plate with excellent impact resistance and manufacturing method of same

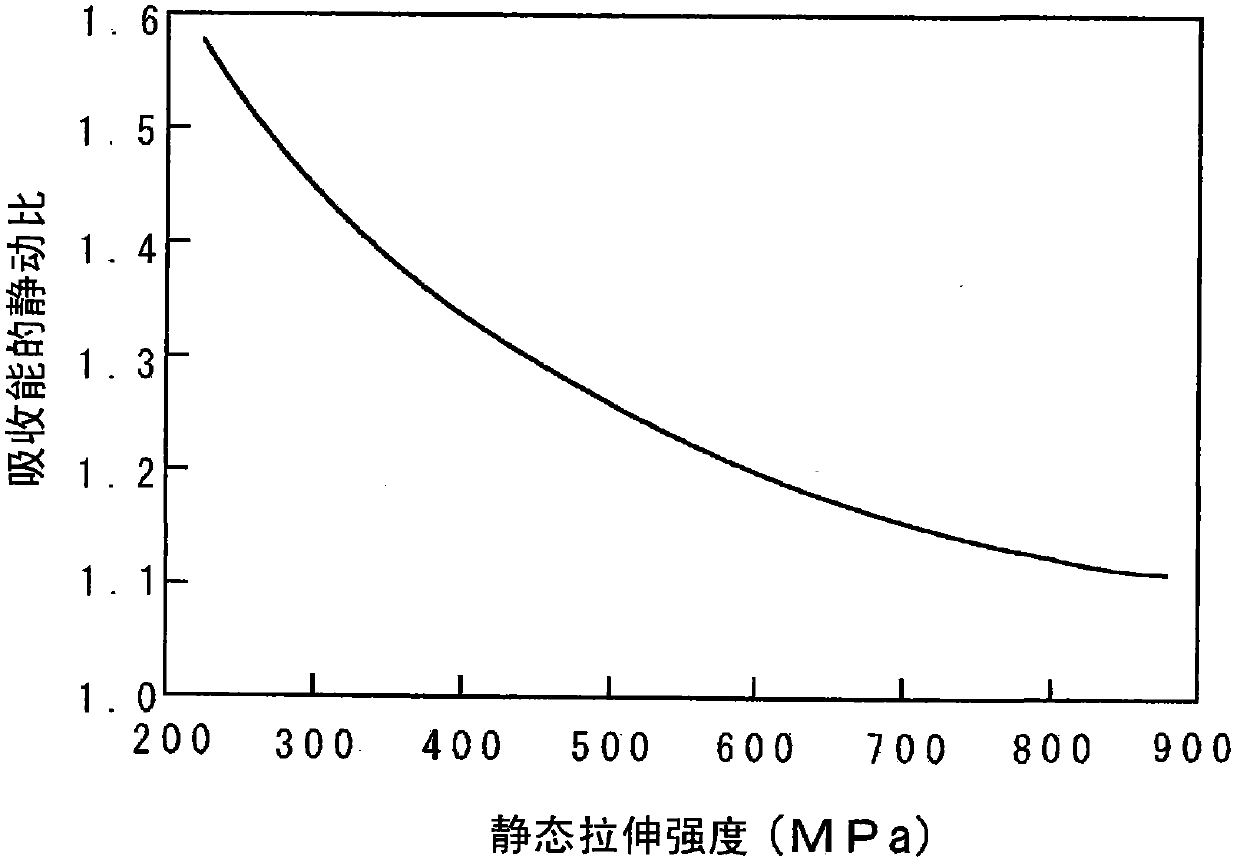

A technology of high-strength steel plate and impact resistance, applied in the field of high-strength steel plate and its manufacturing, can solve problems such as high-strength limitation, and achieve the effect of improving impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

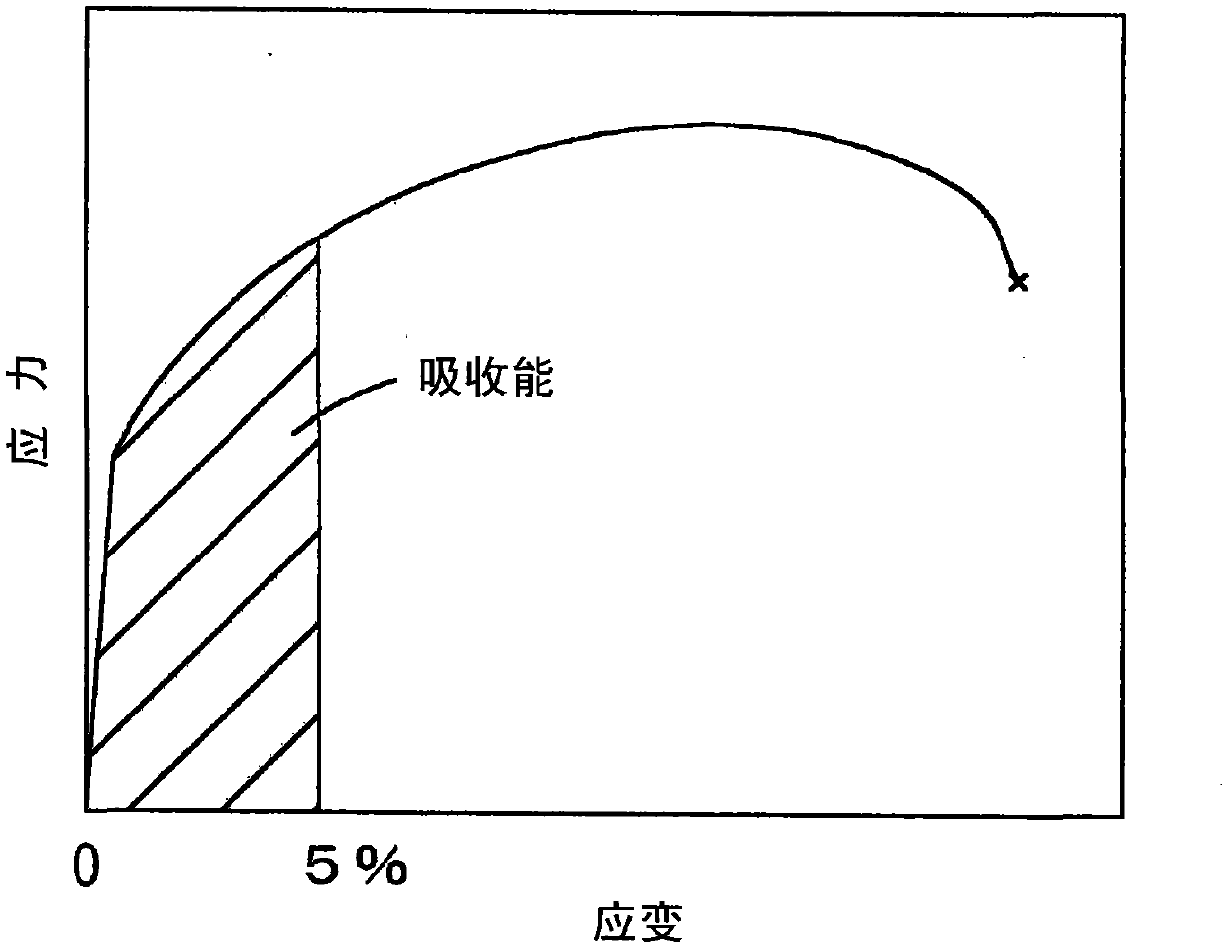

[0021] The steel plate of the present invention has a two-phase structure composed of a predetermined amount of martensite phase and the remainder substantially ferrite phase, and the hardness ratio of the two phases or the amount of solid solution C in ferrite is adjusted to the above-mentioned As for the predetermined value, by limiting the chemical components (mass %) to the following ranges, the impact resistance properties can be effectively improved without degrading various properties such as press formability.

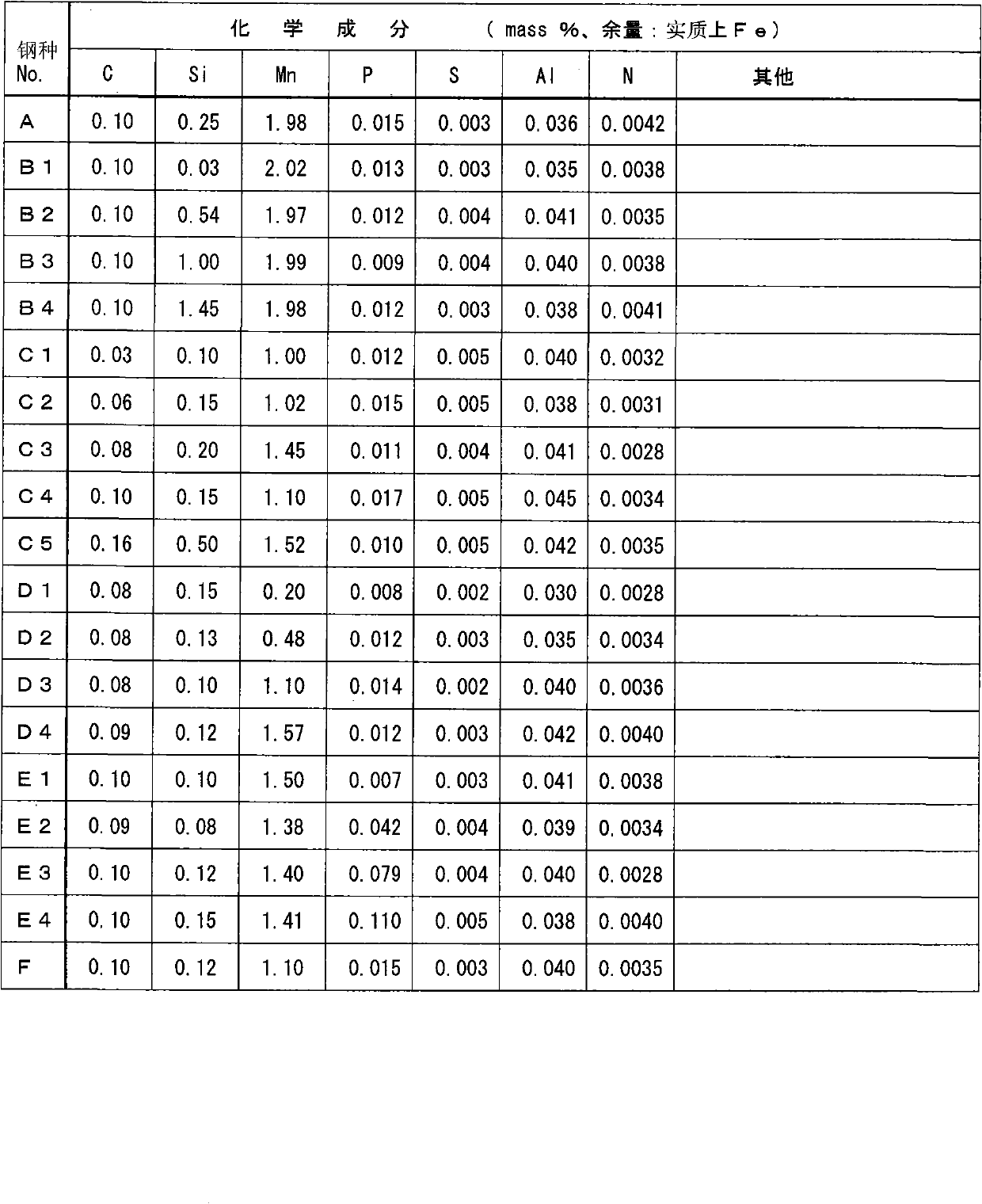

[0022] Contains C: 0.05-0.20%, Si: 2.0% or less, Mn: 0.3-3.0%, P: 0.1% or less, Al: 0.1% or less, and the balance is composed of Fe and unavoidable impurities.

[0023] Alternatively, in addition to the above basic components, any one or more of [Mo: 1.0% or less, Cr: 2.5% or less, B: 0.002% or less], and / or [Ti, Nb, Zr, V: The total amount is 0.4% or less, Cu: 2.5% or less, Ni: 1.5% or less, Ca: 0.02% or less].

[0024] Hereinafter, the reasons for limiting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com