Expanded graphite composite heat storage material as well as preparation method and application thereof

A technology of expanded graphite and composite materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of dehydration kinetics speed restricting large-scale application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

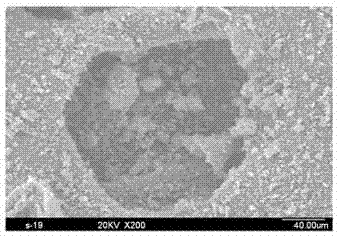

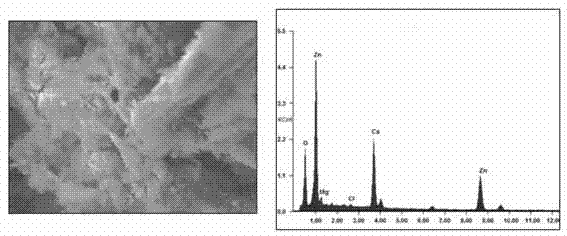

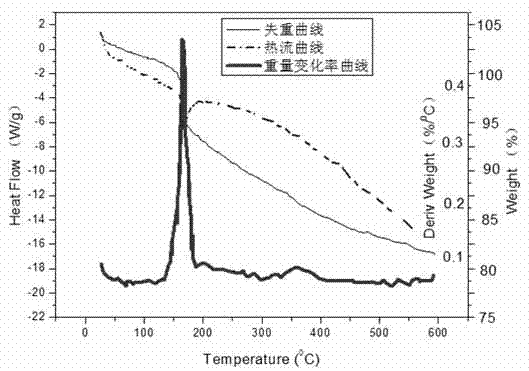

Image

Examples

Embodiment 1

[0022] Add 1000 mL of distilled water to the beaker and heat to 293 K, then add a sufficient amount of ammonium chloride into the beaker, stir well, filter to obtain a saturated ammonium chloride solution, weigh 144 mg of calcium hydroxide and add it to the beaker, stir Make it fully dissolved; weigh 162 mg of zinc oxide and add it to the calcium hydroxide solution, stir continuously, and react continuously for 12 h to obtain a milky white suspension; add 200 mg of powdered expanded graphite to the beaker, Ultrasonic vibration for 24 h; then the solution was left to stand at a temperature of 293 K for about 12 h, and the beaker was placed at a temperature of 353 K for about 10 h to exhaust ammonia and water. After drying, the expanded graphite was taken out and washed with distilled water. Heating to a temperature of 353 K and drying for 10 h, cyclic washing and drying repeated 2-3 times to obtain the final expanded graphite-based calcium-based nanocomposite solar heat storage ...

Embodiment 2

[0024] Add 1000 mL of distilled water to the beaker and heat to 293 K, then add a sufficient amount of ammonium chloride to the beaker, stir well, filter to obtain a saturated ammonium chloride solution, weigh 74 mg of calcium hydroxide and add it to the beaker, And stir to make it fully dissolved; weigh 162 mg of zinc oxide and add it to the prepared calcium hydroxide solution, stir continuously, and react continuously for 12 h to obtain a milky white suspension; place 200 mg of powdered expanded graphite in a beaker, Ultrasonic vibration at a temperature of K for 24 h; then the solution was left to stand at a temperature of 293 K for about 12 h, and the beaker was placed at a temperature of 353 K for about 10 h to exhaust ammonia and water, and the expanded graphite was taken out after drying And the surface was cleaned; the expanded graphite was cooled to room temperature and washed with distilled water; the sample was heated to a temperature of 353 K for about 10 h to dry t...

Embodiment 3

[0026] Add 1000 mL of distilled water to the beaker and heat to 293 K, then add a sufficient amount of ammonium chloride to the beaker, stir well, filter to obtain a saturated ammonium chloride solution, weigh 74 mg of calcium hydroxide and add it to the beaker, And stir to make it fully dissolved; weigh 150 mg of nickel oxide and add it to the prepared calcium hydroxide solution, stir continuously, and react continuously for 12 h to obtain a milky white suspension; place the powdered expanded graphite in a beaker, and heat it at 293 K Ultrasonic vibration at a temperature of 24 h; then the solution was left to stand at a temperature of 293 K for about 12 h, and the beaker was placed at a temperature of 353 K for about 10 h to exhaust ammonia and water. After drying, the expanded graphite was taken out and Clean the surface; cool the removed expanded graphite to room temperature and wash it with distilled water; heat the sample to 353 K for about 10 h to dry the sample. The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com