Core-shell structure type composite flame retardant and preparation method thereof

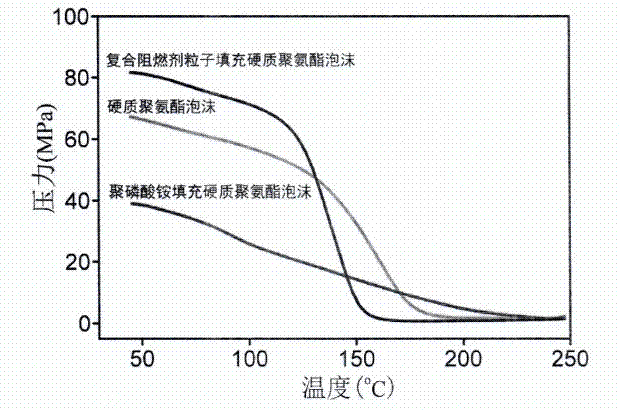

A technology of composite flame retardant and shell structure, which is applied in the field of functionalized core-shell structure composite flame retardant and its preparation, can solve the problem of surface modification of the coating layer, difficulty in compatibility, and damage to the mechanical properties of the polymer matrix and other issues, to achieve the effect of low price, improved water resistance, stable and long-term water resistance and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

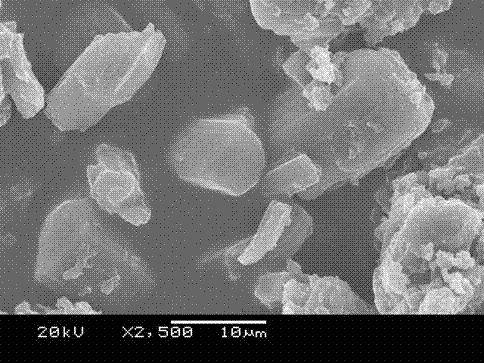

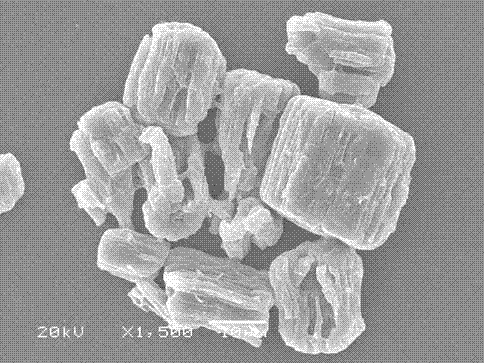

Embodiment 1

[0039] (1) First mix ammonium polyphosphate and distilled water at a mass ratio of 1:10, then add sodium lauryl sulfate whose mass is 1% of the mass of ammonium polyphosphate, and then ultrasonically stir the mixture at 60°C for 1 hour to fully Emulsification, that is, to obtain a stable ammonium polyphosphate suspoemulsion;

[0040] (2) Weigh potassium persulfate whose mass is 1.25% of the mass of ammonium polyphosphate, dissolve it in distilled water to prepare an aqueous solution with a concentration of 0.5% by mass, and then add it to the stable emulsion obtained in step (1) At the same time, feed nitrogen to protect the reaction system in a nitrogen atmosphere, keep the reaction temperature at 60°C, continue mechanical stirring and carry out condensation and reflux. After potassium persulfate is completely decomposed in the system, add a mass of ammonium polyphosphate dropwise. Quality 15% glycidyl methacrylate, the dropping time is controlled at 45 minutes;

[0041] (3)...

Embodiment 2

[0044] (1) First mix ammonium polyphosphate and distilled water at a mass ratio of 1:8, then add sodium dodecylbenzene sulfate whose mass is 2% of the mass of ammonium polyphosphate, and then ultrasonically stir the mixture at 60°C for 1 hour to Fully emulsified to obtain a stable ammonium polyphosphate suspoemulsion;

[0045] (2) Weigh ammonium persulfate whose mass is 2% of the mass of ammonium polyphosphate, and dissolve it in distilled water to prepare an aqueous solution with a concentration of 1% by mass, and then add it to the stable emulsion obtained in step (1) At the same time, feed nitrogen to protect the reaction system in a nitrogen atmosphere, keep the reaction temperature at 60°C, continue mechanical stirring and carry out condensation and reflux. After potassium persulfate is completely decomposed in the system, add a mass of ammonium polyphosphate dropwise. Quality 25% glycidyl methacrylate, the dropping time is controlled within 1 hour;

[0046] (3) React th...

Embodiment 3

[0049] (1) First mix ammonium polyphosphate and distilled water at a mass ratio of 1:9, then add sodium lauryl sulfate with a mass of 1.5% of the mass of ammonium polyphosphate, and then ultrasonically stir the mixture at 60°C for 1 hour to fully Emulsification, that is, to obtain a stable ammonium polyphosphate suspoemulsion;

[0050] (2) Weigh potassium persulfate whose mass is 1% of the mass of ammonium polyphosphate, and dissolve it in distilled water to prepare an aqueous solution with a concentration of 0.75% by mass, and then add it to the stable emulsion obtained in step (1) At the same time, feed nitrogen to protect the reaction system in a nitrogen atmosphere, keep the reaction temperature at 60°C, continue mechanical stirring and carry out condensation and reflux. After the reaction initiator is completely decomposed in the system, add a mass of ammonium polyphosphate dropwise. Quality 20% glycidyl methacrylate, the dropping time is controlled within 30 minutes;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com