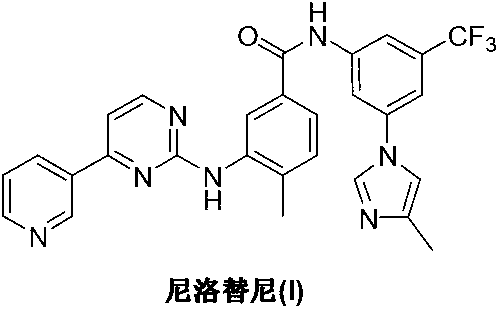

Preparation method of nilotinib

A technology of nilotinib and methyl, applied in the field of nilotinib preparation, can solve the problems of rare raw materials, high cost, long steps, etc., and achieve the effects of controllable production, improved product quality, and promotion of development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

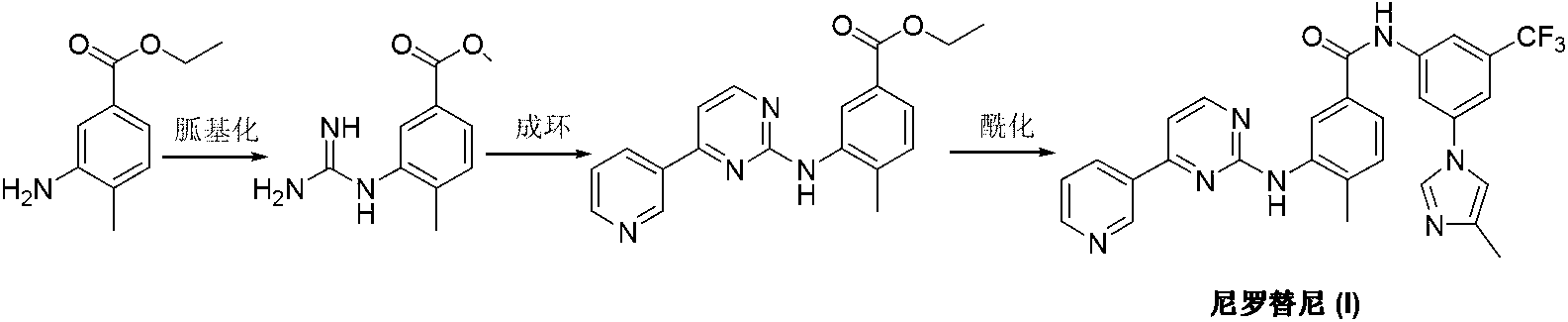

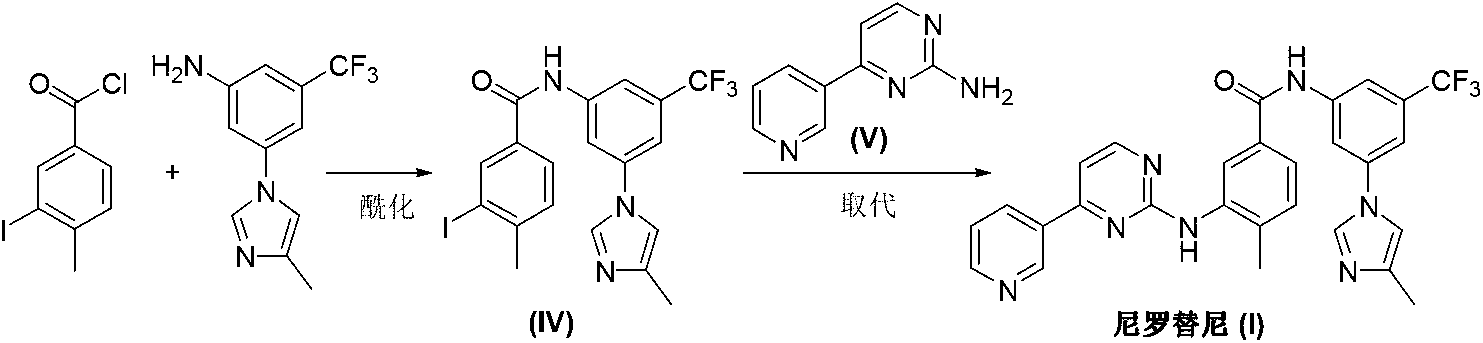

Method used

Image

Examples

Embodiment 1

[0024] Under nitrogen protection, 4-methyl-3-[[4-(3-pyridyl)-2-pyrimidinyl]amino]benzoic acid (II) (3.06g, 10mmol), benzotriazepam Azol-1-yloxytris(dimethylamino)phosphonium hexafluorophosphate (BOP) (6.63 g, 15 mmol) and acetonitrile 50 mL. Under stirring, 1,8-diazabicyclo[5.4.0]-undec-7-ene (DBU) (2.28 g, 15 mmol) was added dropwise, and the reaction was carried out at room temperature for 12 hours. The temperature was raised to 60° C., and the reaction was continued for 12 hours. The solvent was distilled off under reduced pressure, dissolved in 100 mL of ethyl acetate, and washed with 20 mL of 2M sodium hydroxide. The organic phase was separated, dried and concentrated under reduced pressure. The residue was dissolved in 100 mL of tetrahydrofuran, 5-(4-methyl-1H-imidazol-1-yl)-3-trifluoromethylaniline (3.13 g, 13 mmol) and sodium hydride (0.37 g, 15 mmol) were added, and the temperature was raised to 80° C., stirred for 5 hours, and TLC monitored the completion of the r...

Embodiment 2

[0026] Under nitrogen protection, 4-methyl-3-[[4-(3-pyridyl)-2-pyrimidinyl]amino]benzoic acid (II) (3.06g, 10mmol), benzotriazepam Azol-1-yloxytris(dimethylamino)phosphonium hexafluorophosphate (BOP) (6.63 g, 15 mmol) and acetonitrile 50 mL. Under stirring, 1,5-diazabicyclo[4.3.0]-non-5-ene (DBN) (1.86 g, 15 mmol) was added dropwise, and the reaction was carried out at room temperature for 12 hours. The temperature was raised to 60° C., and the reaction was continued for 12 hours. The solvent was distilled off under reduced pressure, dissolved in 100 mL of ethyl acetate, and washed with 20 mL of 2M sodium hydroxide. The organic phase was separated, dried and concentrated under reduced pressure. The residue was dissolved in 100 mL of tetrahydrofuran, 5-(4-methyl-1H-imidazol-1-yl)-3-trifluoromethylaniline (3.13 g, 13 mmol) and sodium hydride (0.37 g, 15 mmol) were added, and the temperature was raised to 50° C., stirred for 5 hours, and TLC monitored the completion of the rea...

Embodiment 3

[0028] Under nitrogen protection, 4-methyl-3-[[4-(3-pyridyl)-2-pyrimidinyl]amino]benzoic acid (II) (3.06g, 10mmol), benzotriazepam Azol-1-yloxytris(dimethylamino)phosphonium hexafluorophosphate (BOP) (6.63g, 15mmol), 5-(4-methyl-1H-imidazol-1-yl)-3-tri Fluoromethylaniline (3.13 g, 13 mmol) and N,N-dimethylformamide 50 mL. Under stirring, 1,8-diazabicyclo[5.4.0]-undec-7-ene (DBU) (4.56 g, 30 mmol) was added dropwise, and the reaction was carried out at room temperature for 12 hours. The temperature was raised to 60° C., and the reaction was continued for 12 hours. The solvent was distilled off under reduced pressure, dissolved in 100 mL of ethyl acetate, and washed with 20 mL of 2M sodium hydroxide. The organic phase was separated, dried and concentrated under reduced pressure. The residue was recrystallized from tetrahydrofuran / ethyl acetate (4:1) to obtain 4.32 g of off-white solid nilotinib (I), with a yield of 81.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com