Method for preparing 12-hydroxy stearic acid through utilizing hydrogenerated castor oil as raw material

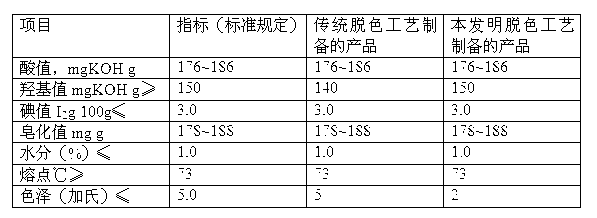

A technology of hydrogenated castor oil and hydroxystearic acid, applied in chemical instruments and methods, preparation of oxygen-containing compounds, preparation of organic compounds, etc., can solve the problems of yellowing in appearance color, yellowing in color of 12-hydroxystearic acid, etc. , to achieve the effect of color appearance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Taking hydrogenated castor oil as the method for raw material preparation 12-hydroxystearic acid, specifically comprises the following steps:

[0028] Raw material selection: hydrogenated castor oil is used as raw material; the hydrogenated castor oil is obtained from castor beans through hot pressing, and then hydrogenated to obtain hydrogenated castor oil;

[0029] Saponification: add alkali to saponify hydrogenated castor oil, add alkali until the pH of the solution reaches 12, and obtain saponified product; the alkali added is sodium hydroxide; the alkali used in the following examples is sodium hydroxide;

[0030] Acidification: add acid to the saponified product, add dilute sulfuric acid until the pH reaches 2; the acid added is dilute sulfuric acid, and the dilute sulfuric acid is obtained by diluting 98% concentrated sulfuric acid with one volume of water; used in the following examples The added acid that arrives is dilute sulfuric acid, and described dilute su...

Embodiment 2

[0043] Taking hydrogenated castor oil as the method for raw material preparation 12-hydroxystearic acid, specifically comprises the following steps:

[0044] Raw material selection: hydrogenated castor oil is used as raw material; the hydrogenated castor oil is obtained from castor beans through hot pressing, and then hydrogenated to obtain hydrogenated castor oil;

[0045] Saponification: add alkali to hydrogenated castor oil for saponification, add alkali until the pH of the solution reaches 12, and obtain saponified products;

[0046] Acidification: add acid to the saponified product, add dilute sulfuric acid until the pH reaches 2;

[0047] Washing: add the same volume of water as hydrogenated castor oil, and wash with water until neutral to obtain 12-hydroxystearic acid;

[0048] Decolorization: add hydrogen peroxide for decolorization, the concentration of the hydrogen peroxide is 15%, its addition is 2% of the weight of hydrogenated castor oil, and the decolorization t...

Embodiment 3

[0052] Taking hydrogenated castor oil as the method for raw material preparation 12-hydroxystearic acid, specifically comprises the following steps:

[0053] Raw material selection: hydrogenated castor oil is used as raw material; the hydrogenated castor oil is obtained from castor beans through hot pressing, and then hydrogenated to obtain hydrogenated castor oil;

[0054] Saponification: add alkali to hydrogenated castor oil for saponification, add alkali until the pH of the solution reaches 12, and obtain saponified products;

[0055] Acidification: add acid to the saponified product, add dilute sulfuric acid until the pH reaches 2;

[0056] Washing: add the same volume of water as hydrogenated castor oil, and wash with water until neutral to obtain 12-hydroxystearic acid;

[0057] Decolorization: add hydrogen peroxide for decolorization, the concentration of the hydrogen peroxide is 30%, its addition is 2-8% of the weight of hydrogenated castor oil, and the decolorization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com