Device and method for realizing synchronous anaerobic ammonia oxidation and denitrification anaerobic methane oxidation

A technology of nitrifying anaerobic methane and anaerobic ammonia oxidation, which is applied in anaerobic digestion treatment, waste fuel and other directions, can solve the problems of slow growth and difficulty in enrichment and cultivation of Anammox bacteria and N-DAMO bacteria, and achieves the solution of organic carbon source. insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

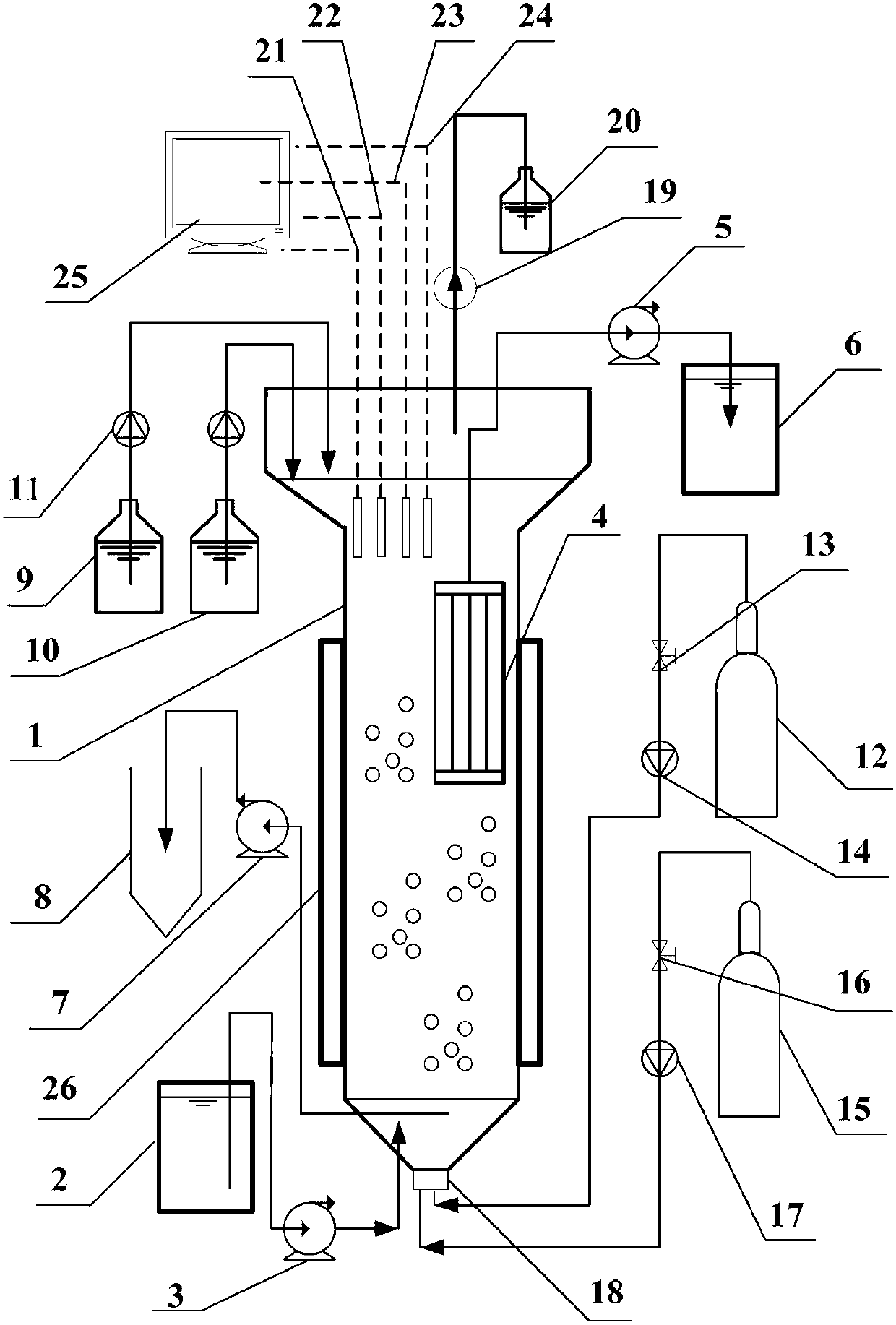

[0042] see figure 1 As shown in the figure, a device based on the synergistic effect of Anammox and N-DAMO bacteria to achieve greenhouse gas emission reduction in sewage biological treatment, mainly set up a membrane biofilm reactor 1, and configure an inlet tank 2, an automatic control system 25 and an outlet tank 6. The water inlet tank 2 is connected to the membrane biofilm reaction 1 through the inlet water pump 3 . The membrane biofilm reactor 1 is provided with a membrane module 4 , and the outlet end above the membrane module is connected to the outlet pump 5 through a pipeline, and the outlet water finally enters the outlet tank 6 . The acid-base solution in the acid buffer bottle 9 and the alkaline buffer bottle 10 are respectively added into the membrane biofilm reactor 1 through the acid-base dosing peristaltic pump 11 to adjust the pH level in the membrane biofilm reactor 1 . The methane in the methane gas storage tank 12 is adjusted by the pressure reducing val...

Embodiment 2

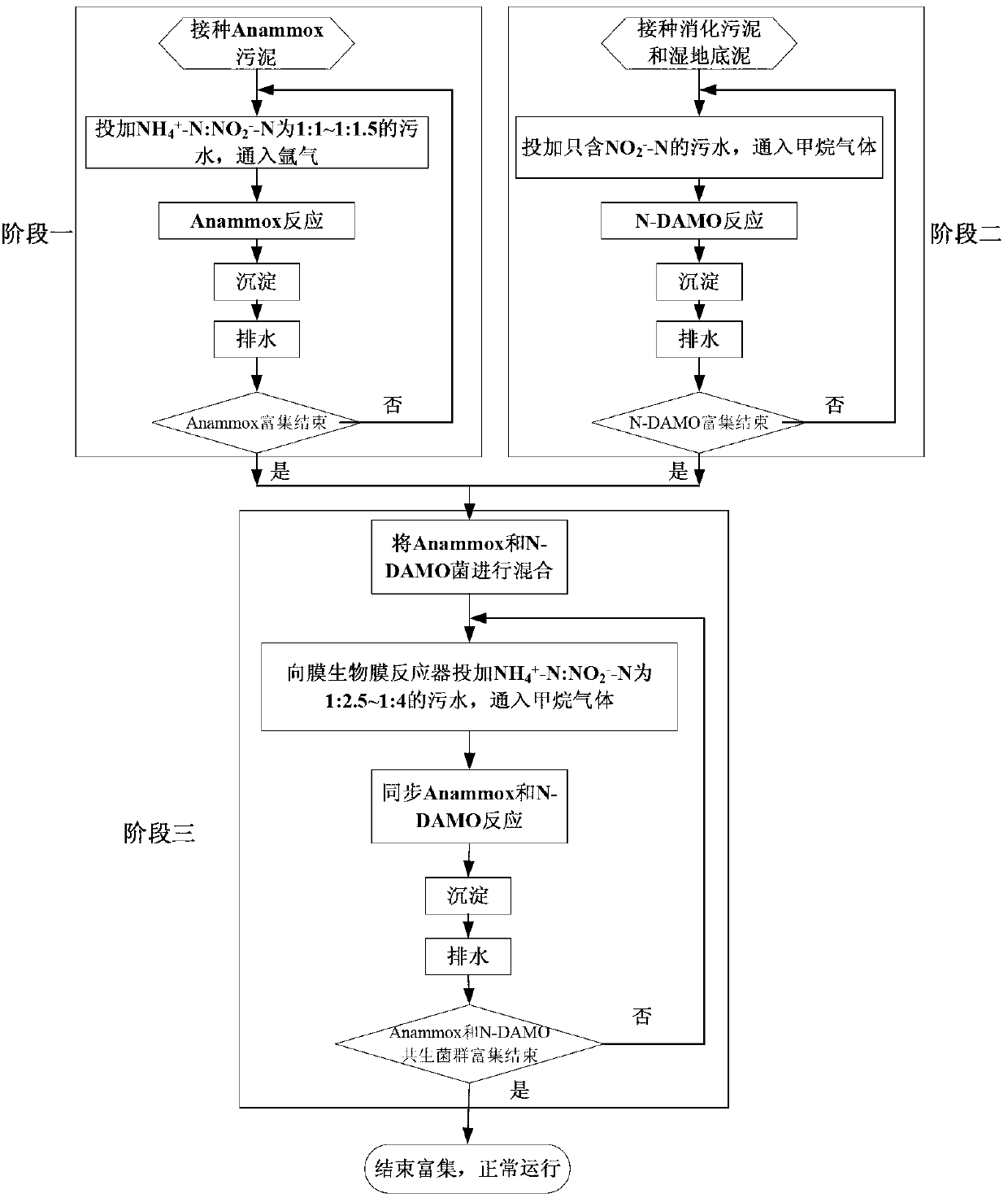

[0044] see figure 2 As shown, a method to achieve simultaneous anammox and denitrification anaerobic methane oxidation, using the first culture strategy of culturing separately and then co-cultivating, cultivating and domesticating the symbiotic flora of Anammox and N-DAMO bacteria, To achieve simultaneous anammox and denitrification anaerobic methane oxidation processes, the strategy is divided into the following three stages:

[0045] Stage 1: First inoculate the sludge containing Anammox strains into the membrane biofilm reactor, and extract the NH containing 4+ -N and NO 2 - -N sewage is added to the membrane biofilm reactor. After the water inflow is completed, only the argon gas flowmeter is turned on instead of the methane gas flowmeter to ensure anaerobic conditions so that Anammox bacteria can metabolize NH 4 + -N and NO 2 - -N grows and reproduces; after the anammox reaction is over, turn on the outlet water pump to discharge the supernatant liquid filtered by...

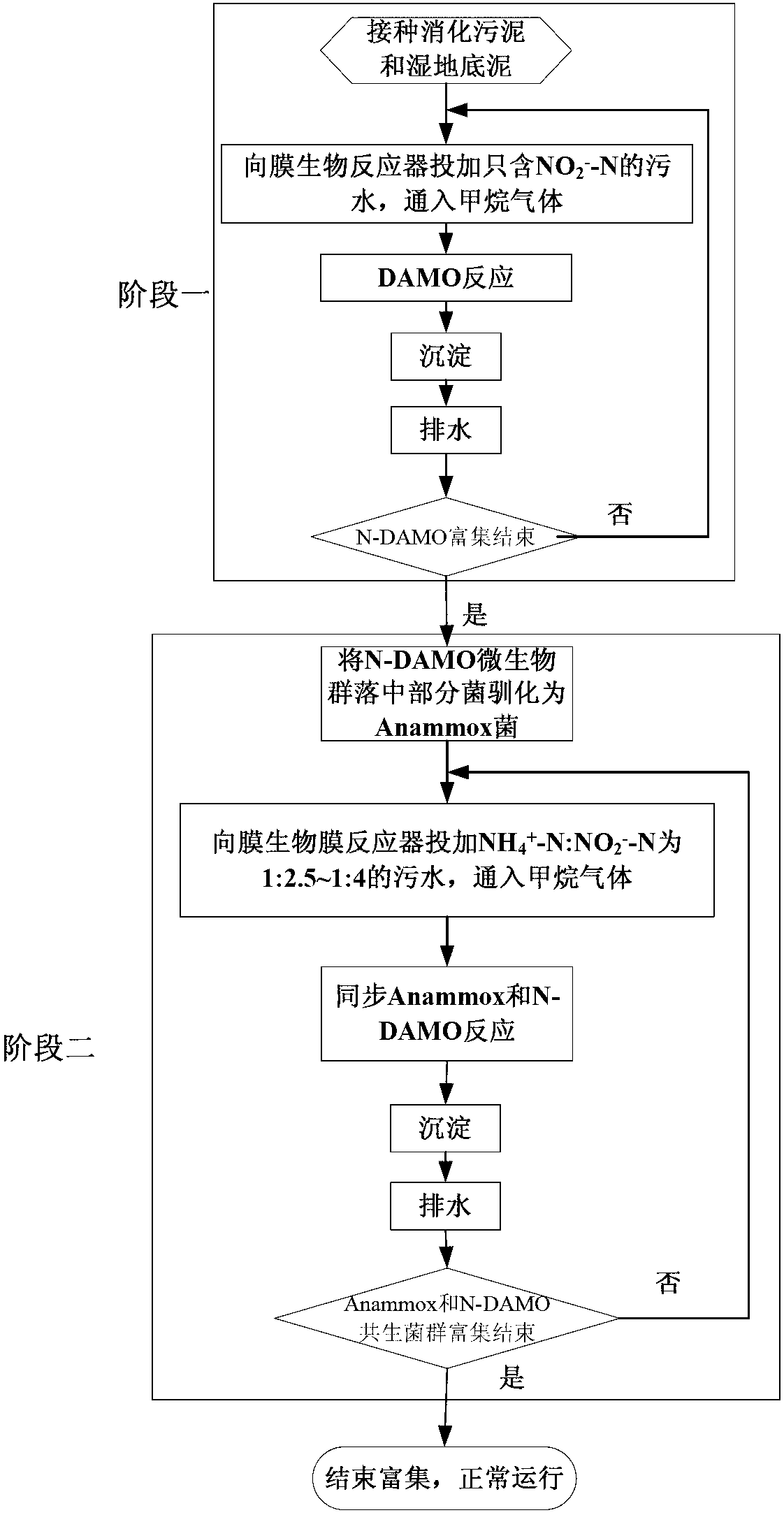

Embodiment 3

[0049] The inoculated sludge for start-up and acclimation came from the sludge in the anaerobic sludge digester and the bottom sludge of a natural wetland. Anammox and N-DAMO bacteria were cultivated and acclimated using the first culture strategy of separate cultivation and then co-cultivation. The symbiotic flora can realize the simultaneous anaerobic ammonia oxidation and denitrification anaerobic methane oxidation process, and the realization process is divided into the following three stages.

[0050] In the first stage, the NO 2 - -N concentration is 50-120mg / L, NH 4 + - Sewage with a N concentration of 50-100mg / L was added to the 10L membrane biofilm reactor SMBR. After the water inflow was completed, only the argon gas flowmeter was turned on instead of the methane gas flowmeter, and samples were taken every 2 hours for analysis NH in SMBR reactor 4 + -N and NO 2 - -N concentration, when the test result shows NH 4 + -N or NO 2 - - When the N concentration is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com