Preparation method for ethanol gas sensor based on vanadium pentoxide multilevel nanometer network structure

A vanadium pentoxide nanometer and gas sensor technology, which is applied in the direction of material resistance, etc., can solve the problem that the sensitive performance of nanostructured gas sensitive materials can be fully exerted, which affects the performance stability and reliability of gas sensor elements, and is unfavorable for device miniaturization and integration. to avoid the secondary transfer process, improve the application range and application field, and achieve good response-recovery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of alumina interdigitated platinum electrode

[0038] The aluminum oxide sensor substrate was ultrasonically cleaned in acetone solvent, absolute ethanol, and deionized water, and then thoroughly dried, and then placed in the vacuum chamber of the ultra-high vacuum magnetron sputtering equipment with high-purity metal platinum as the target material. Argon gas with a mass purity of 99.999% is used as the working gas, the sputtering working pressure is 2.0Pa, the sputtering power is 80-90W, the sputtering time is 8-10min, the substrate temperature is room temperature, and interdigitated platinum electrodes are formed on the surface of alumina ;

[0039] (2) Preparation of seed solution

[0040] Dissolve an appropriate amount of ammonium metavanadate in deionized water, stir magnetically until the solution turns light yellow, add an appropriate amount of dilute nitric acid to control the pH of the solution at about 2.1-2.5, and form an orange-red color wi...

Embodiment 2

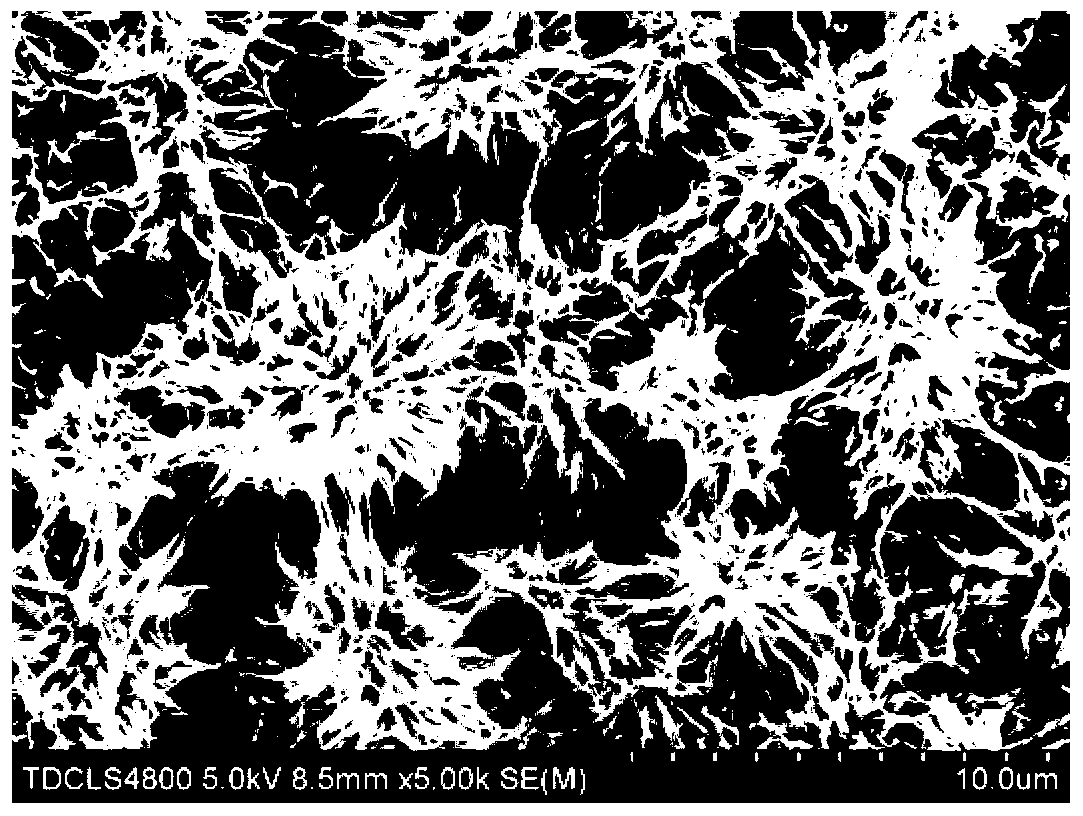

[0051] The difference between this example and Example 1 lies in that the concentration of ammonium metavanadate in the hydrothermal reaction solution in step (5) is changed to 0.06M, and the vanadium oxide multilevel nano-network gas-sensing material is prepared. Scanning electron microscopy analysis of the surface morphology showed that image 3 As shown, there are a large number of dispersed nanoflowers, showing a porous structure, and are closely connected by overlapping nanowires and nanobelts, and the nanoflowers are radial structures composed of nanoneedles and nanowires, with a large specific surface area , can make ethanol gas "in and out" freely, so that it has higher sensitivity and faster dynamic response. Figure 5-8 It further reflects its dual working temperature for ethanol gas, as well as faster response / recovery characteristics and selectivity characteristics.

Embodiment 3

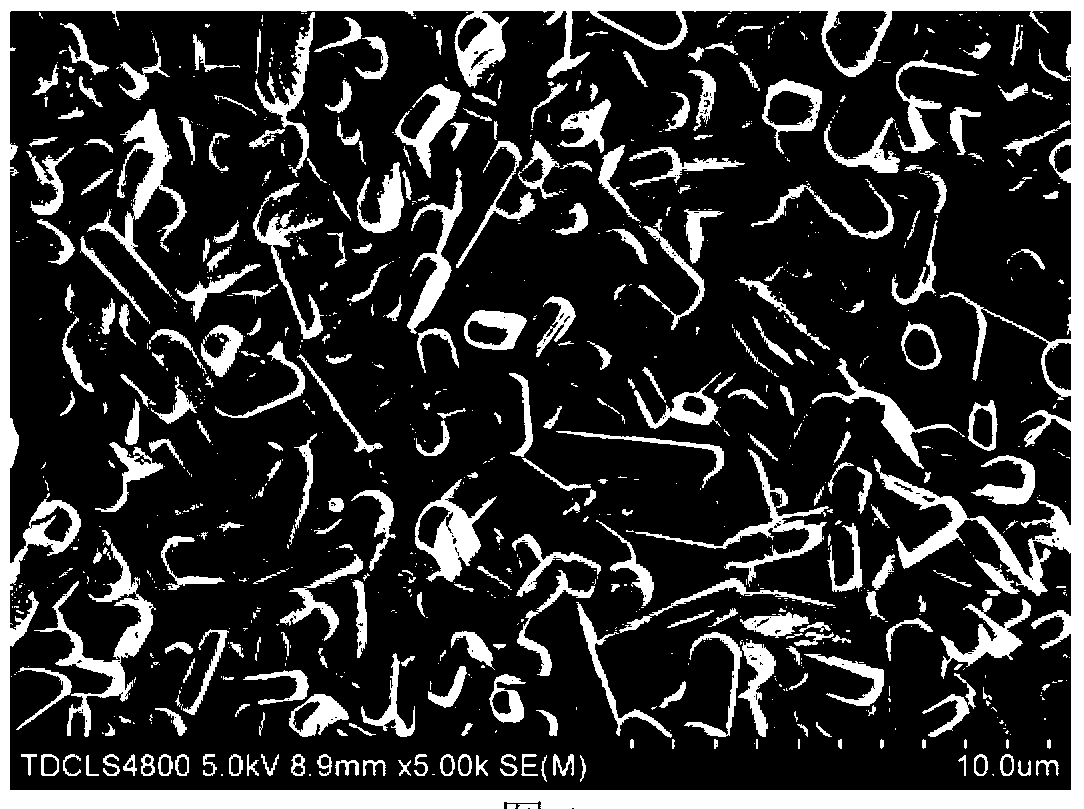

[0053] The difference between this example and Example 1 lies in that the concentration of ammonium metavanadate in the hydrothermal reaction solution in step (5) is changed to 0.08M, and the vanadium oxide multilevel nano-network gas-sensing material is prepared. Scanning electron microscopy analysis of the surface morphology showed that Figure 4 As shown, there are spherical honeycomb-shaped nanoflowers in close contact with each other, with an average diameter of about 3-5 μm, and also presents a porous structure.

[0054] The invention adopts the static gas distribution method to measure the sensitivity characteristics of vanadium pentoxide multi-level nano-network structure sensor elements to ethanol gas within the temperature range from room temperature to 300°C, and defines the sensitivity S=Rg / Ra of the gas sensor element, wherein Rg, Ra are the resistance values of the element in the detection gas and dry air, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com